Grouting construction method for steel-structured base

A construction method and steel structure technology, which is applied in the direction of building structure, construction, and building material processing, can solve problems affecting the strength and expansion of slurry, slurry leakage, slurry bleeding and settlement, etc., and achieve good durability , high strength, dense slurry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

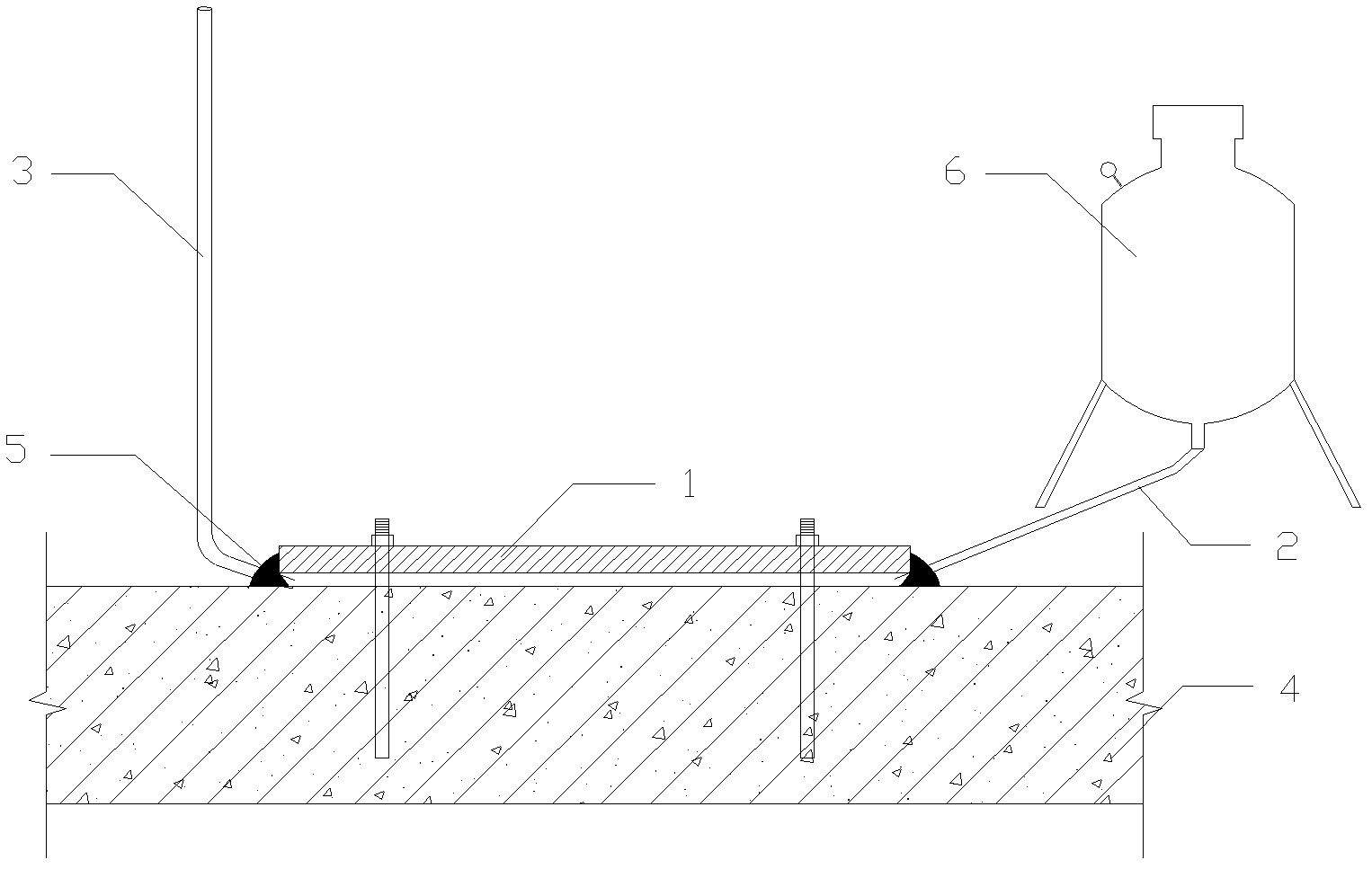

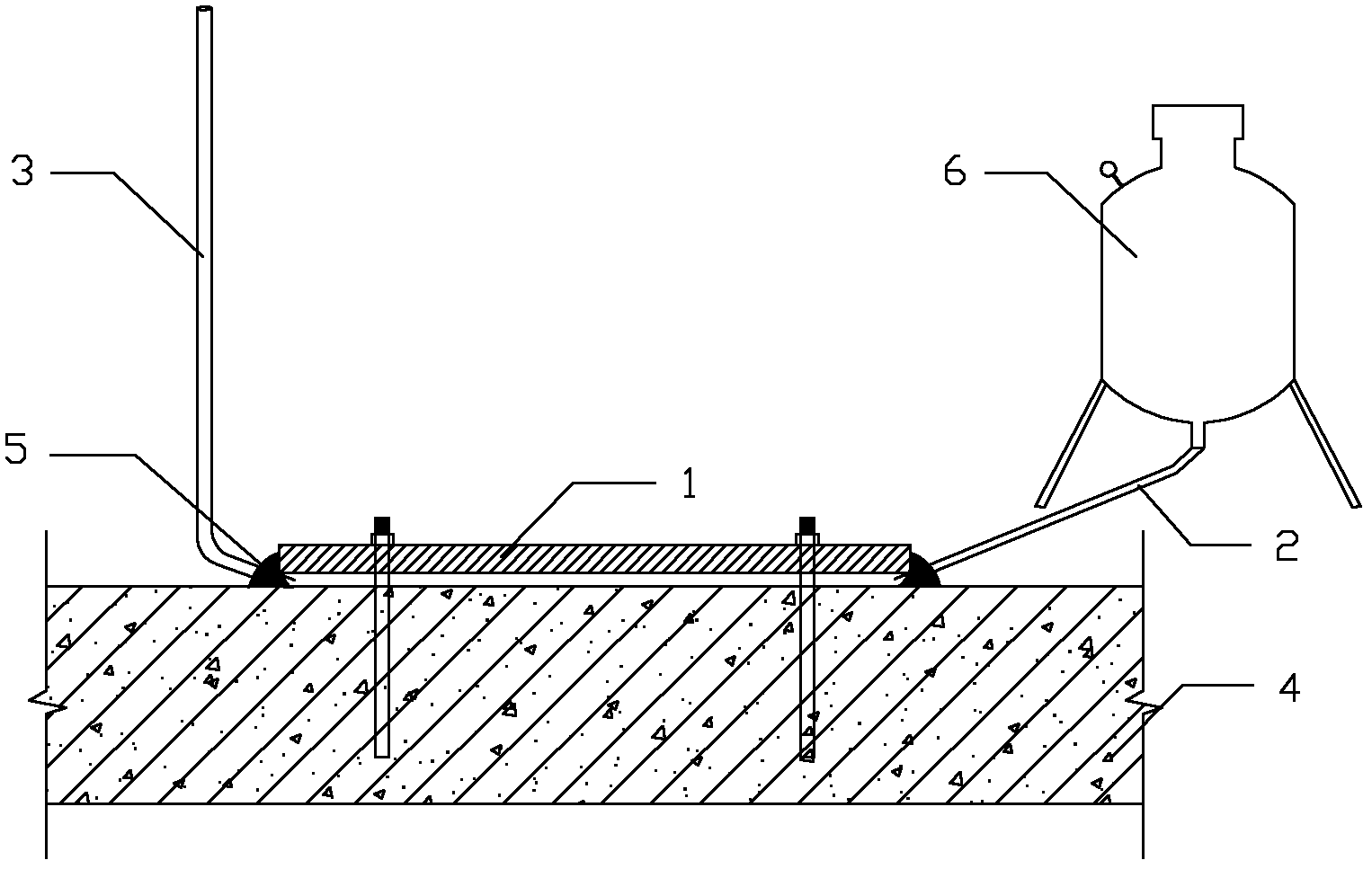

[0018] Such as figure 1 As shown, a steel base grouting construction method includes the following steps:

[0019] Step 1: Chisel away the concrete around the pre-embedded steel structure base 1 and remove the chiseled loose concrete, remove the laitance, and blow off the dust accumulation under the steel structure base 1 with a fan;

[0020] Step 2: bury the grouting pipe 2 and the overflow pipe 3 between the steel structure base 1 and the concrete base 4 with plugging Wang cement 5, and seal the edges around the steel structure base 1 with quick-drying cement, and the overflow The height of the pipe 3 is higher than the upper surface of the steel base 1;

[0021] Step 3: Carry out a ventilation test, the intake of the grouting pipe 2 and the outlet of the overflow pipe 3, to ensure that there is no air leakage in other parts except the grouting pipe 2 and the overflow pipe 3;

[0022] Step 4: Configure grouting materials and perform grouting, and stop grouting when the ove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com