Energy recycling device for excavator hydraulic system

A technology of energy recovery device and hydraulic excavator, which is applied in the direction of earth mover/shovel, construction, etc., can solve the problems of shortening the service life of components, large damage of hydraulic system, increasing fuel consumption, etc., to reduce the scope and reduce Energy loss, effect of improving fuel economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

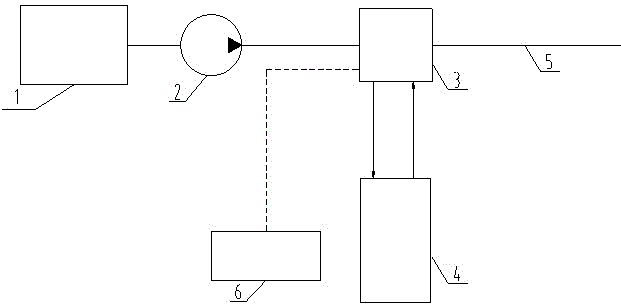

[0013] The present invention will be further described below in combination with principle diagrams and specific operation examples.

[0014] Such as figure 1 As shown, the energy recovery device used in the rear side of the hydraulic excavator main pump includes an engine 1, a main pump 2, a controllable valve group 3, an accumulator 4, a main oil circuit 5, and a controller 6. The energy recovery device Located behind the main pump 2, the main pump 2 is connected to the engine 1, the controllable valve group 3 is located on the main oil circuit 5, and one end is connected to the main pump 2. The oil inlet port and the oil return port of the accumulator 4 are respectively connected with corresponding ports on the controllable valve group 3 . The energy recovery device of the present invention also includes a signal acquisition device (not shown in the figure), and the signal acquisition device can be a common sensor on the market that can measure liquid pressure, such as a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com