Drilling, expanding and cleaning integrated reverse-circulation rotating squeezed branch pile machine

A technology of squeezing and expanding branched piles and reverse circulation, which is applied in sheet pile walls, buildings, infrastructure engineering, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

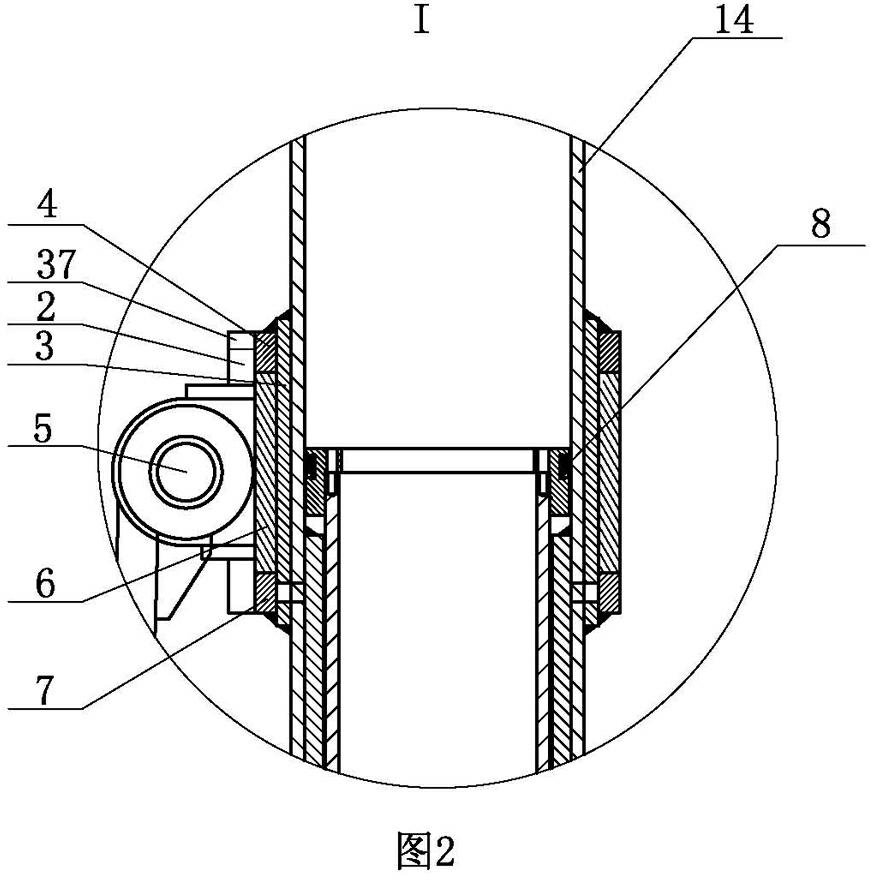

[0009] The drilling, expanding and clearing integrated reverse circulation rotary extruded and expanded branch pile machine according to the present invention includes an outer tube 14 and an inner tube 15, the inner tube 15 is located in the outer tube 14, and the inner tube 15 and the outer tube 14 are connected to form a telescopic Rod; the inner wall of the outer tube 14 is provided with an outer tube guide strip 11. The outer wall of inner tube 15 is provided with vertical guide groove, is provided with vertical guide block in the guide groove, and the part between guide groove near one end of outer pipe 14 to guide block is rotating groove 38, and guide groove is positioned at guide block one. The side and the part that can cooperate with the outer tube guide bar 11 is the vertical movement groove 30. The outer tube guide bar 11 cooperates with the vertical movement groove 30, and the outer tube guide bar 11 can move vertically in the vertical movement groove 30. The ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com