Double heat energy heating biogas system

A technology of biogas and thermal energy, which is applied in the field of biogas engineering, can solve the problems of high investment and operation cost, low gas production rate, low cost performance, etc., and achieve the effect of good warming effect, low cost and strong environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

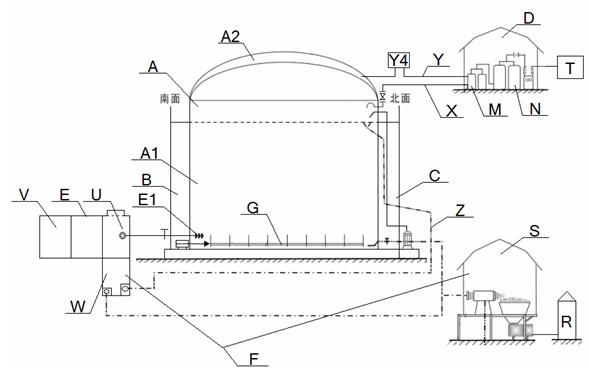

[0149] A biogas system with dual heat energy heating, including a fermenter A, a feeding device E, a biogas purification device D, and a biogas residue treatment device F. A stirring device G is installed inside the fermenter A, and a temperature increasing device is arranged outside the fermenter A. The heating device includes a solar heating device B and an auxiliary thermal heating device C; the feeding device E includes a deployment tank U and at least two sedimentation tanks V, and the biogas purification device D includes a multifunctional automatic regulator M and a purifier N, the biogas residue treatment device F includes a biogas slurry waste heat conduction pool W and a solid-liquid separator S, and the slag outlet of the solid-liquid separator S is connected to the biological fertilizer equipment R;

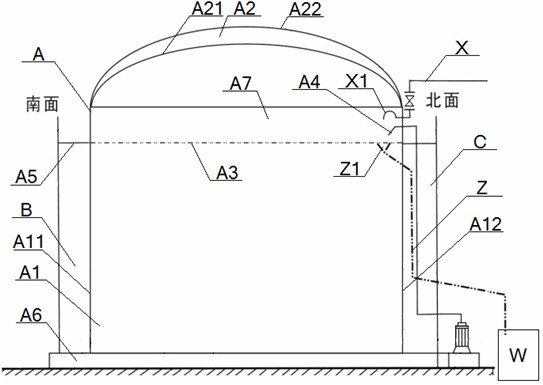

[0150] The fermenter A includes a tank body A1 and an air film A2 provided on its top. The air film A2 includes an inner film A21 and an outer film A22. The inside of ...

Embodiment 2

[0169] The basic situation is the same as that of Example 1, the difference is that: the solar heating device B is the No. The solar heating room J is connected with the direct heating room K of the fully enclosed boiler. The width of the direct heating room K of the fully enclosed boiler is 0.6 meters, and the width of the No. 2 solar heating room J is 0.5 meters;

[0170] The No. 2 solar warming room J includes an arc-shaped transparent glass wall H1 and a closed door H2. The transparent glass wall H1 is arranged around the south side wall A11. The two ends of the transparent glass wall H1 are respectively connected to the closed door H2 and the No. The wall K1 is connected, and the top of the transparent glass wall H1 is provided with a platform A5; the fully enclosed boiler direct heating room K includes a curved No. 2 thermal insulation brick wall K1, entry I2 and a fully enclosed safe and energy-saving biogas boiler L , the No. 2 thermal insulation brick wall K1 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com