Preparation method of pigment preparations containing superfine phthalocyanine pigment particles

A technology of pigment preparation and phthalocyanine pigment, applied in the direction of organic dyes, etc., can solve the problems of large particle size, poor adsorption, wide distribution, etc., and achieve the effects of simple and easy preparation method, avoiding large particle size and simple use method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Pigment preparations were prepared as follows:

[0049] a). Take 1000 grams of 98.0wt.% concentrated sulfuric acid, put in 200 grams of phthalocyanine blue (P.B.15:1) pigment at 35°C and a stirring speed of 300r / min for dispersion, and dissolve the pigment completely to form a homogeneous solution Finally, filter the pigment solution with a glass filter element filter bucket to obtain a homogeneous pigment solution, wherein the phthalocyanine blue comes from Jiangsu Shuangle Chemical Pigment Co., Ltd.;

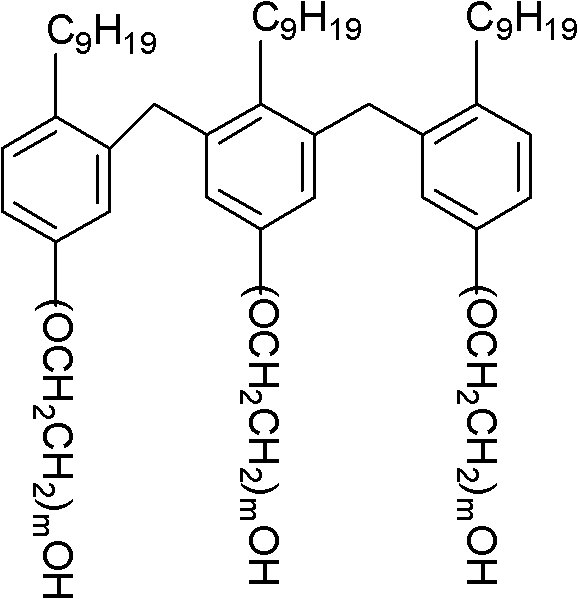

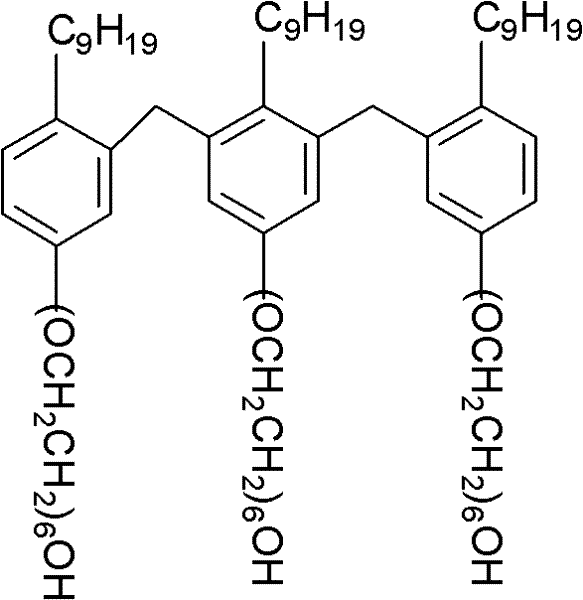

[0050] b). The homogeneous pigment solution obtained in step a) and 0.4 gram of phthalocyanine derivative A are added to 1000 gram of dispersant aqueous solution (this dispersant aqueous solution contains 50 gram of dispersant DS-A, and the balance is deionized water), Disperse at a stirring speed of 70°C and 300r / min for 20 minutes until the dispersion is uniform, then lower it to 45°C, keep the temperature and let stand for 3 hours to facilitate the precipitation of the...

Embodiment 2

[0055] Pigment preparations were prepared as follows:

[0056] a). Take 1000 grams of 90wt.% concentrated sulfuric acid, at 70 ° C and a stirring speed of 1000r / min, drop into 400 grams of phthalocyanine green (P.G.7) pigments to disperse, after the pigments are completely dissolved to form a homogeneous solution, use Filter the pigment solution with a glass filter hopper to obtain a homogeneous pigment solution, in which the phthalocyanine blue comes from Jiangsu Shuangle Chemical Pigment Co., Ltd.;

[0057] b). The homogeneous pigment solution obtained in step a) and 4 grams of phthalocyanine derivatives B are added to 2000 grams of dispersant aqueous solution (the dispersant aqueous solution contains 100 grams of dispersant DS-B, and the balance is deionized water), Disperse at a stirring speed of 95°C and 300r / min for 20 minutes until the dispersion is uniform, then lower it to 55°C, keep the temperature and let stand for 8 hours to facilitate the precipitation of the prod...

Embodiment 3

[0062] Pigment preparations were prepared as follows:

[0063] a). Take 1000 grams of 95.0wt.% concentrated sulfuric acid, put in 300 grams of phthalocyanine blue (P.B.15:3) pigment at 55°C and a stirring speed of 300r / min for dispersion, and dissolve the pigment completely to form a homogeneous solution Finally, filter the pigment solution with a glass filter element filter bucket to obtain a homogeneous pigment solution, wherein the phthalocyanine blue comes from Shanghai Jiehong Pigment Chemical Group Co., Ltd.;

[0064] b). The homogeneous pigment solution obtained in step a) and 6 grams of phthalocyanine derivative C are added to 2000 grams of dispersant aqueous solution (the dispersant aqueous solution contains 50 grams of dispersant DS-B, and the balance is deionized water), Disperse at 80°C and a stirring speed of 300r / min for 20 minutes until the dispersion is uniform, then lower to 50°C, keep the temperature and let stand for 3 hours to facilitate product precipitati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com