Rope-binding prevention device for quickly changing head rope of mine hoist

A technology of mine hoist and head rope, which is applied in the direction of lifting equipment, transportation and packaging in mines, to achieve the effect of improving safety factor, saving labor intensity and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

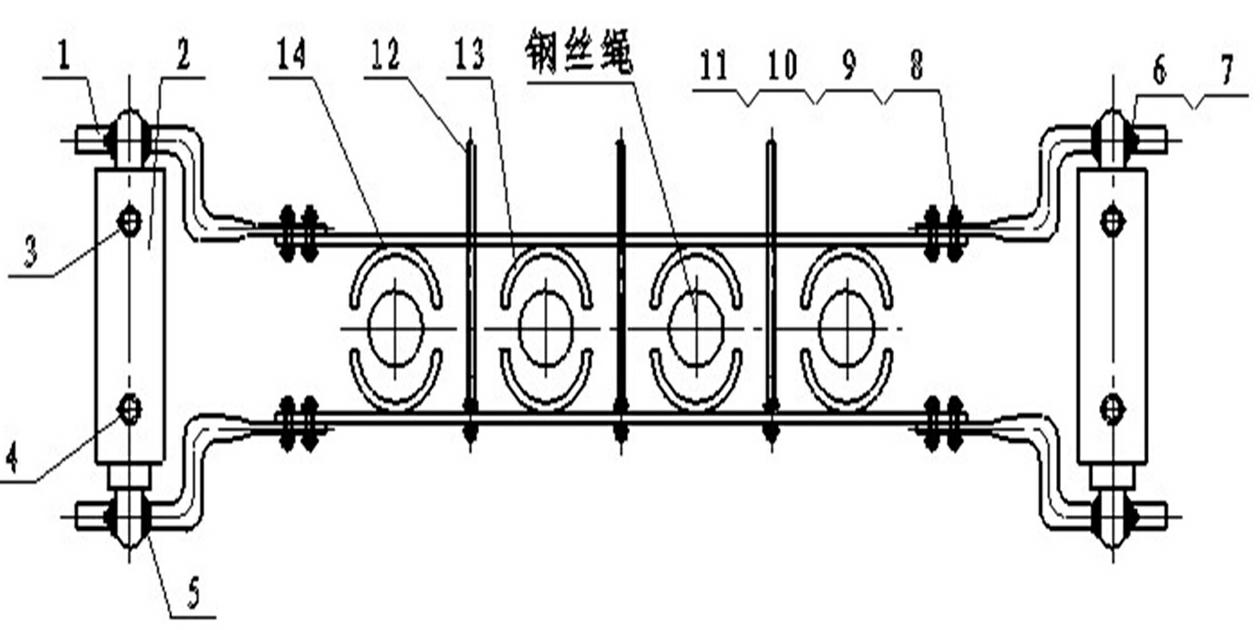

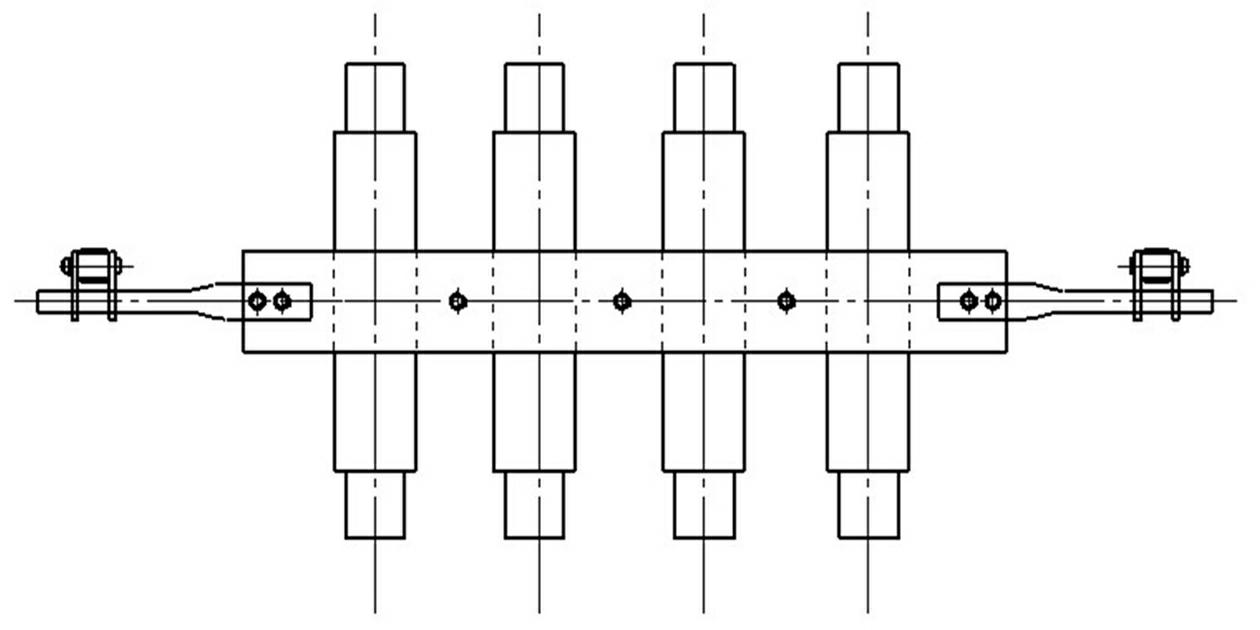

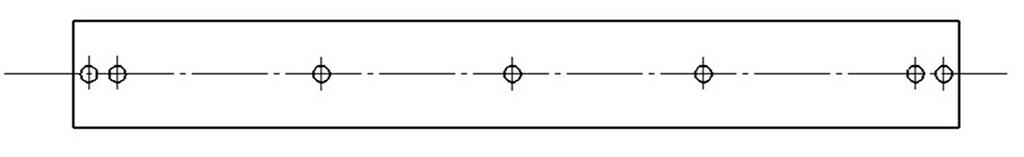

[0025] Steel pipes and steel plates are selected according to the wire rope diameter, spacing and length. Drill 7 holes respectively on the steel plate 14, then at one end of the steel plate 14, be respectively fixed with three guide rods 12 by nut, flat washer, spring washer. The selected steel pipe is cut into two halves, and then welded on the steel plate 14. At the same time, the baffle plate 5 is welded on the "Z" elbow 1, and the "Z" elbow 1 and the steel plate 14 are connected and fixed by bolts 8, nuts 9, flat washers 10, and spring washers 11. Steel plate 14, half-section steel pipe 12 and " Z " font elbow 1 are now connected into a whole, and it is buckled on the wire rope, then cylinder 2 is fixed on baffle plate 5 places with bearing pin 6, cotter pin 7.

[0026] When the steel wire rope is lowered normally, the steel wire rope is lowered in the two half-cut steel pipes 12. Since the air inlet and outlet passages of the cylinder are closed, even if the steel wire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com