Food packing system

A food packaging and material inlet technology, which is applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of low weighing accuracy, increased labor intensity, and reduced production efficiency, and achieves simple structure and reduced labor. Strength and the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

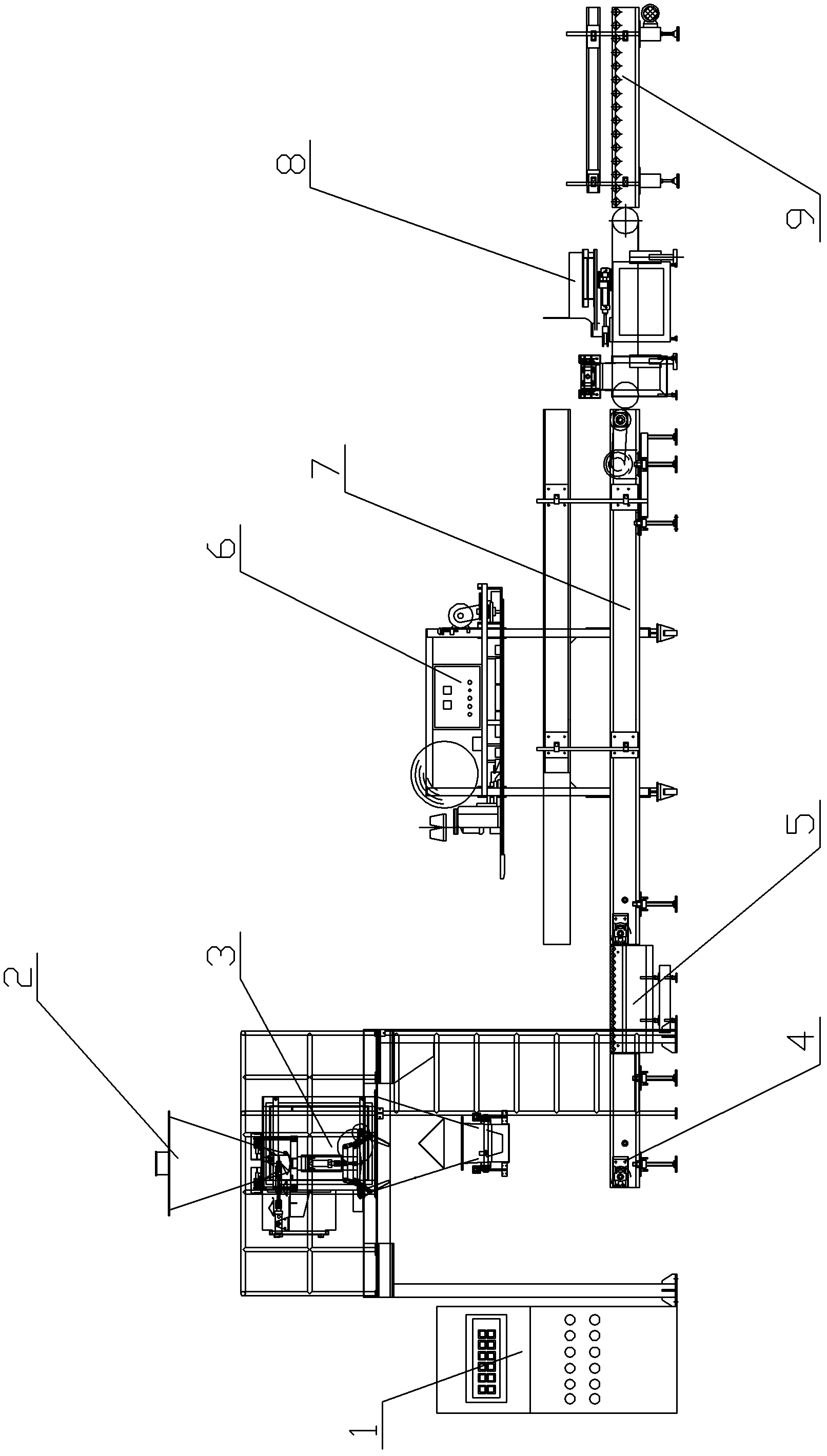

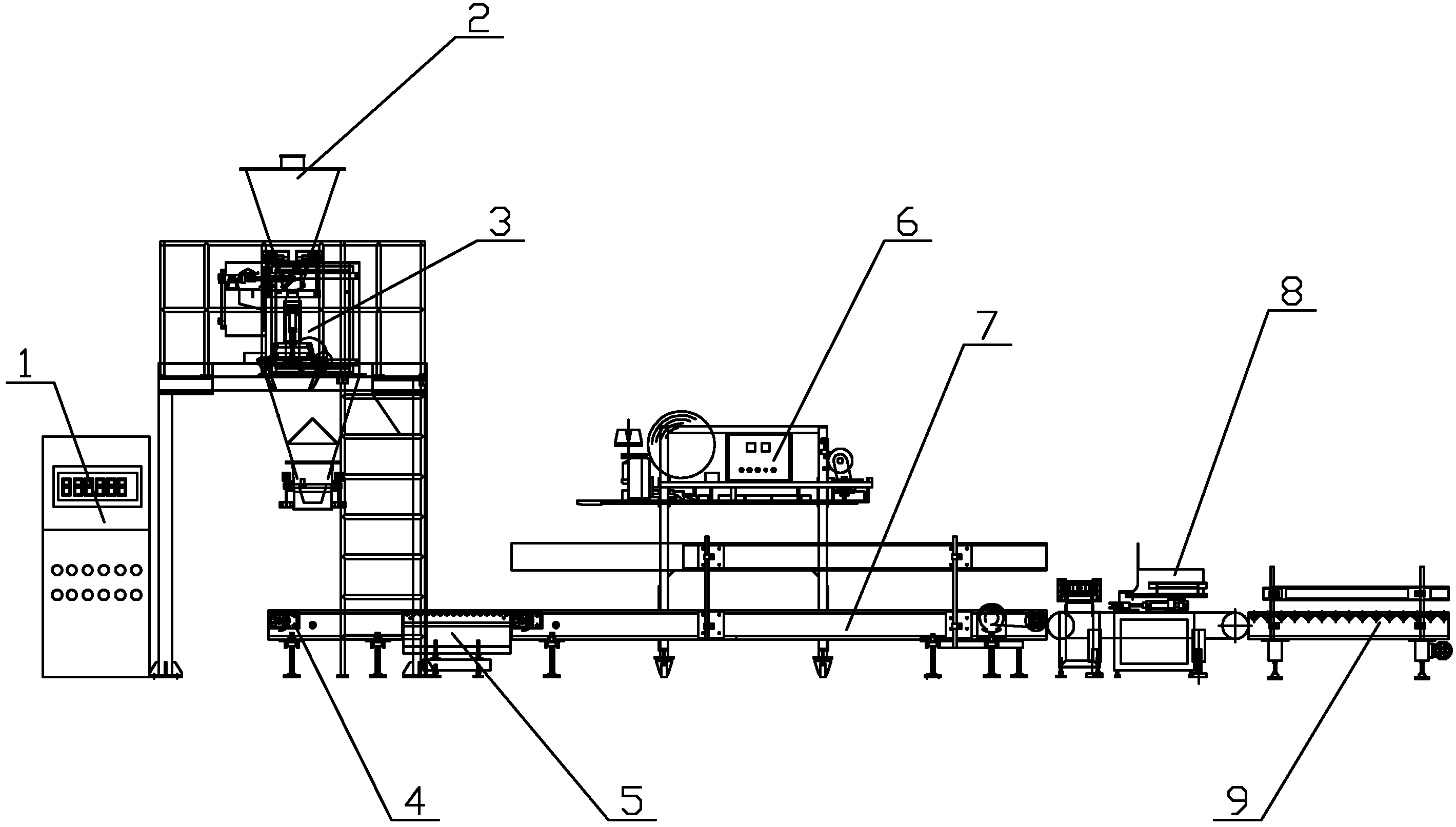

[0015] Please refer to figure 1 As shown, in this embodiment, a food packaging system includes a net weight scale 3, a verification scale 5, a heat sealing machine 6, a bag dumping machine 8, a shaping machine 9, and an electric control cabinet 1 for controlling the above-mentioned machines, The net weighing scale 3 is composed of a hanging load cell, a weighing body and a weighing display. The feeding port of the verification scale 5 is connected through the weighing conveyor 4, the transition bin 2 is a conical structure, and a slide valve is provided at the bin mouth, and the discharge port of the verification scale 5 passes through The heat sealing conveyor 7 is connected to the feed port of the bag dumping machine 8, and the heat seal conveyor 7 is provided with a heat sealer 6, and the discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com