Two-dimensional laser cutting machine

A two-dimensional laser and laser cutting head technology, applied in the field of improvement, can solve the problems of large motion inertia, bulkiness, and low operating accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

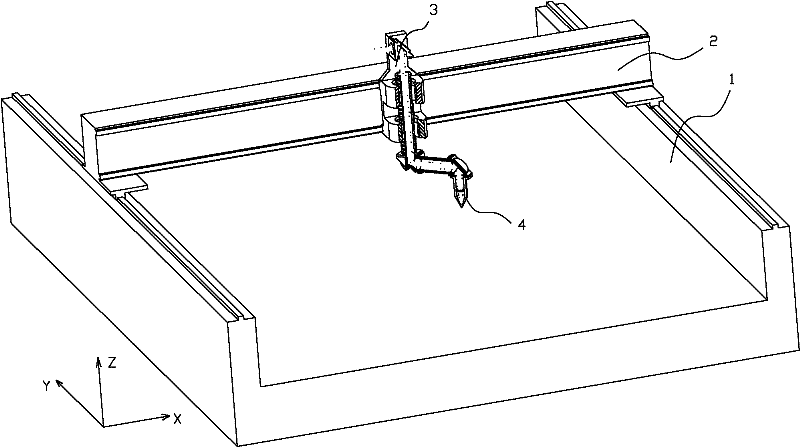

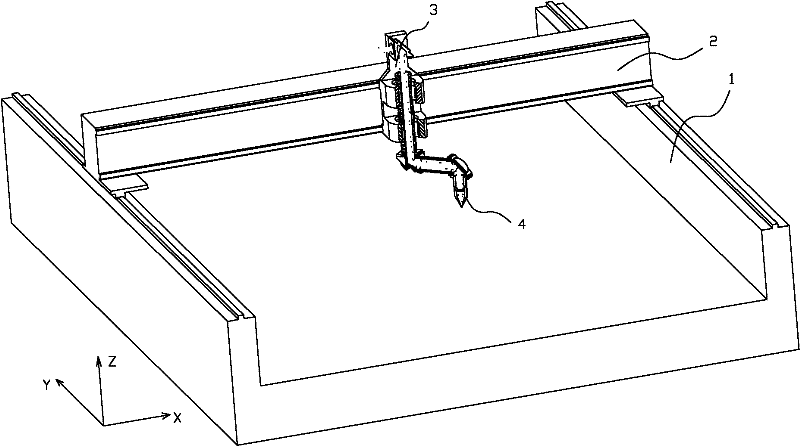

[0016] The invention as figure 1 , 2 As shown, the laser cutting machine includes a body 1, a beam 2, a laser cutting head 4 and a laser generator. The body 1 and the beam 2 are connected to each other through an X-guiding guide provided on the body, and the side of the beam is provided with a Y Guide rail, the laser cutting head 4 is movably connected to the Y guide rail on the side of the beam 2 through the local motion mechanism 3 (in figure 1 The X, Y, Z coordinate system is marked in the middle);

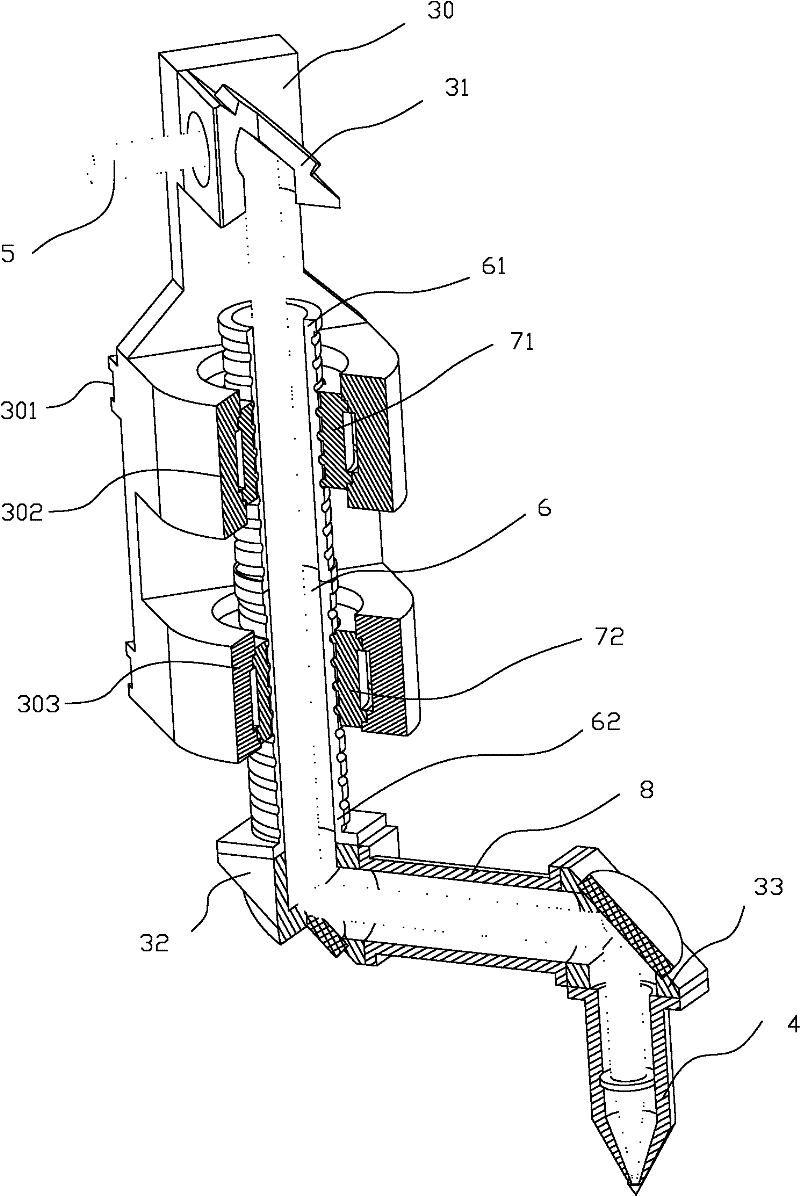

[0017] The local motion mechanism includes a Y-direction motion support 30, a bidirectional hollow screw shaft 6, a light guide cylinder 8, a screw nut 1 71, a drive motor 1, a screw nut 2 72, a drive motor 2 and at least two mirror groups (reflector mirror group one 32, mirror group two 33);

[0018] The back side of the Y-direction movement support 30 is provided with a chute 301 for connecting the Y guide rail; the front side of the Y-direction movement support 30 is prov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com