Micro-robot driven by ciliary vibration

A micro-robot, vibration-driven technology, applied in the fields of vaccination, ovulation diagnosis, medical science, surgery, etc., can solve problems such as damage, application pipeline scratches, and robot application limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

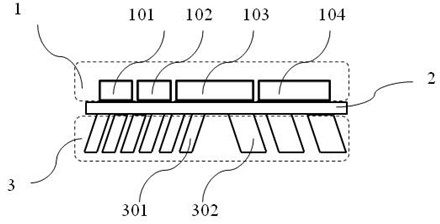

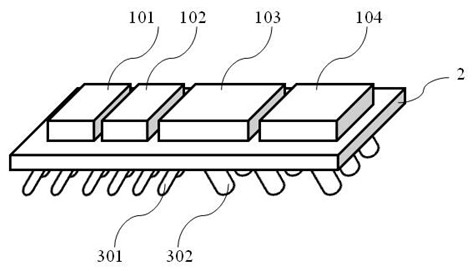

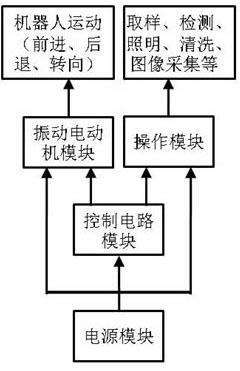

[0027] see figure 1 and figure 2 , the micro-robot is composed of a three-layer structure. The upper structure 1 includes a power supply module 101, a control circuit module 102, a vibration motor module 103 and an operation module 104; the middle layer structure 2 is a substrate for supporting and connecting; The functional cilia driving legs are divided into the first group of cilia driving legs 301 and the second group of cilia driving legs 302 . The two groups of ciliary driving legs in the lower structure 3 have different numbers, different diameters, and symmetrical inclination angles. They are processed under the middle layer structure 2 through abrasive infusion technology, and form a whole with the middle layer structure 2. The middle layer structure 2 and the lower structure 3 are all made of PDMS material, which has good flexi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com