Preparation method of infant livestock and poultry fructose probiotics feed

A fructose and feed technology, applied in the field of enzyme preparations, microorganisms, and feed, can solve the problems of low content of anti-nutritional factors, poor palatability, and unsound digestive function, and achieve low content of anti-nutritional factors, good palatability, and balanced amino acids Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

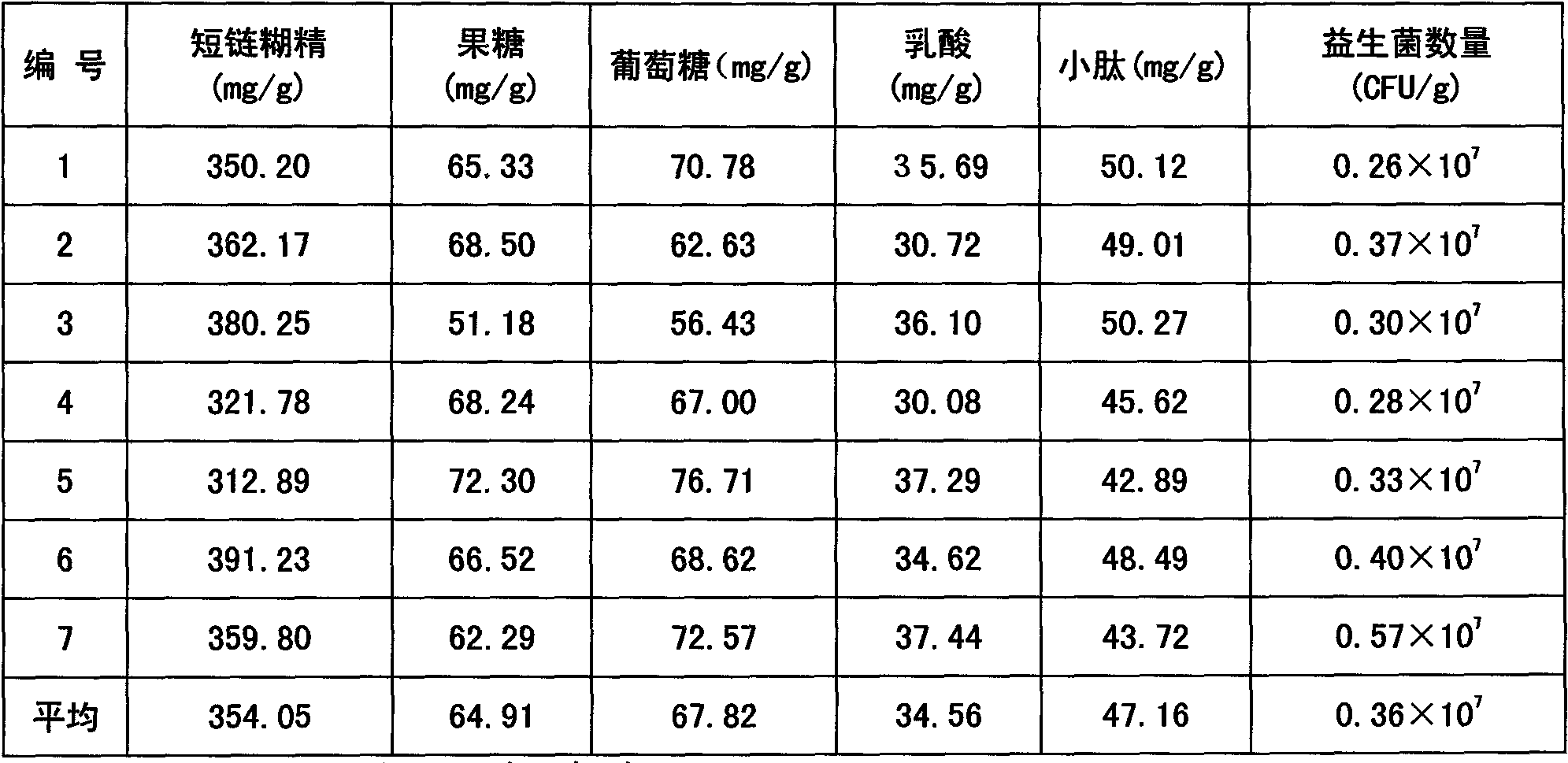

Examples

Embodiment 1

[0032] Remove impurities and crush 450kg corn, 50kg wheat, 100kg broken rice, 150kg glucose and 50kg soybean meal, mix well, then add 1500kg water, 20kg molasses and calcium chloride (just a small amount, the same below) and other nutrients, and use 20% hydrogen Adjust the pH of the calcium oxide solution to 6.5, prepare a fermented liquid, heat up to 95-120°C for sterilization, inoculate 40 kg of Bacillus licheniformis seed liquid when the temperature is lowered to 38-40°C, and ferment for 108 hours at a temperature of 38-40°C. Then the temperature was raised to 95-105°C for liquefaction and enzymatic hydrolysis for 2 hours. Then lower the temperature of the fermented liquid to 65-70°C, add 0.45 kg of glucose isomerase, perform isomerization at 60-70°C for 16 hours to obtain fructose liquid, and dry the fructose liquid to make A component.

[0033] After removing impurities and crushing 200kg of soybean meal, add 150kg of water, mix evenly and heat up to 38-40°C, add 10kg of ...

Embodiment 2

[0036] Remove impurities and pulverize 3000kg corn, 500kg wheat, 1000kg broken rice, 2500kg glucose and 500kg soybean meal, mix well, then add 20000kg water, 180kg molasses and a small amount of calcium chloride and other nutrients, adjust the pH to 6.5. Prepare fermentation broth, heat up to 95-120°C for sterilization, inoculate 500kg of Bacillus licheniformis seed liquid when the temperature drops to 38-40°C, ferment at 38-40°C for 108 hours, then heat up to 95-105°C Carry out liquefaction and enzymatic hydrolysis for 2.5h. Then lower the temperature of the fermented liquid to 65-70°C, add 6.0kg of glucose isomerase, and perform isomerase hydrolysis at 60-70°C for 15 hours. The grain dextrin liquid and fructose liquid produced by the above-mentioned fermentation enzymolysis are dried to make A component.

[0037]After removing impurities and crushing 2500kg of soybean meal, add 1200kg of water, mix evenly and heat up to 38-40°C, add 100kg of Saccharomyces cerevisiae seed li...

Embodiment 3

[0040] Remove impurities and grind 200kg corn, 30kg wheat, 50kg broken rice, 100kg glucose and 20kg soybean meal, mix them evenly, then add 750kg water, 12kg molasses and a small amount of calcium chloride and other nutrients, and adjust the pH to 6.5. Prepare fermentation broth, heat up to 95-120°C for sterilization, inoculate 20kg of Bacillus licheniformis seed liquid when the temperature drops to 38-40°C, ferment at 38-40°C for 108 hours, then heat up to 95-105°C Carry out liquefaction and enzymatic hydrolysis for 3h. Then lower the temperature of the fermented liquid to 65-70°C, add 0.5kg of glucose isomerase, and perform isomerase hydrolysis at 60-70°C for 18 hours. The grain dextrin liquid and fructose liquid produced by the above-mentioned fermentation enzymolysis are dried to make A component.

[0041] After removing impurities and crushing 100kg of soybean meal, add 120kg of water, mix evenly and heat up to 38-40°C, add 3kg of Saccharomyces cerevisiae seed liquid, 3k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com