Hot air concentrated processing system for drying dried noodles

A centralized processing and hot air technology, applied in the direction of dough processing, application, baking, etc., can solve the problems of high energy consumption loss, unexplained structure, and hidden hygiene hazards in dried noodles, so as to improve the utilization rate of heat energy, stabilize the temperature and humidity, and improve the quality. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

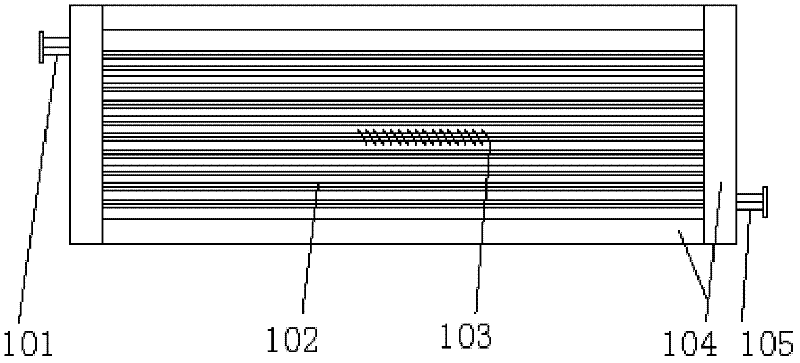

[0040] Such as figure 1 As shown, the present invention provides a kind of hot air centralized treatment system that is used for dry dried noodles, comprising: drying chamber 1, air supply and exhaust device, temperature and humidity adjustment device, centralized treatment box 8 and air filtering device, wherein the air supply and exhaust device , including exhaust fan 7 and air supply fan 19, exhaust fan 7 communicates with drying chamber 1 through exhaust duct 6, and air supply fan 19 communicates with drying chamber 1 through air supply duct 2; temperature and humidity adjustment device is used for all The temperature and humidity adjustment in the drying chamber is described; the centralized treatment box 8 is a closed structure, and the temperature and humidity adjustment device is arranged in the centralized treatment box 8, and an air inlet pipe 15 is arranged on it, and the two ends of the air supply pipe 2 are connected to the drying chamber 1 and the drying chamber r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com