Device and method for estimating performance degradation of equipment based on inspection system

A technology of equipment performance and inspection system, which is applied in the direction of instruments, character and pattern recognition, computer parts, etc., can solve the problems of unconnected enterprises, poor reliability, and increased equipment maintenance costs, so as to reduce economic losses and apply Wide-ranging, easy-to-focus effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

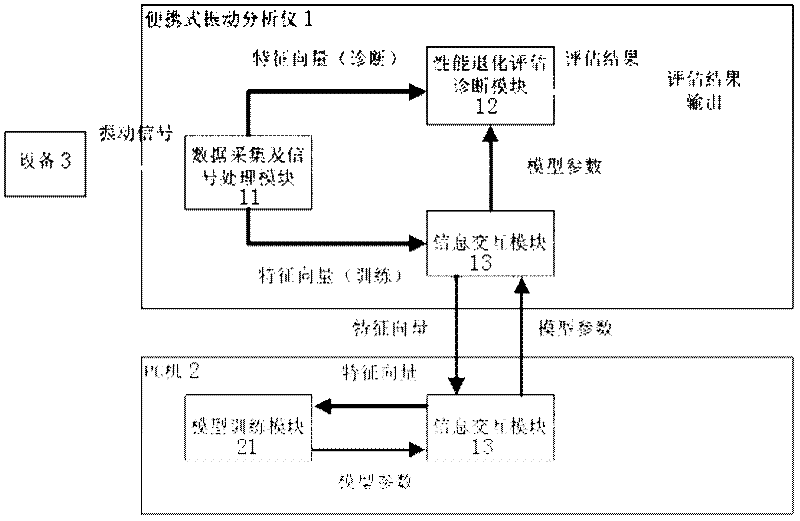

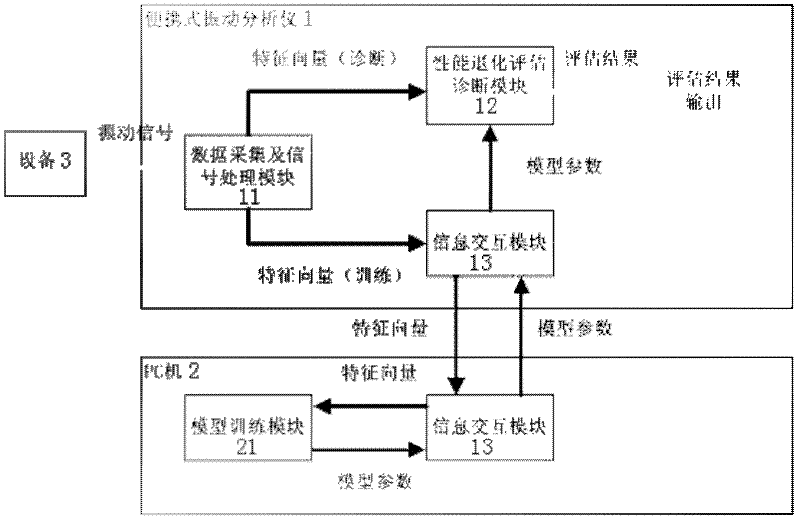

[0024] like figure 1 As shown, the equipment performance degradation assessment device based on the inspection system provided by the present invention includes a portable vibration analyzer 1 and a PC 2, both of which constitute the inspection system in the present invention. The portable vibration analyzer 1 includes a data acquisition and signal processing module 11 , a performance degradation assessment and diagnosis module 12 , and an information interaction module 13 , and the PC 2 includes an information interaction module 13 and a model training module 21 . The data acquisition and signal processing module 11 extracts feature vectors that reflect the degradation of equipment performance, including feature vectors of training data and feature vectors of diagnostic data, wherein the feature vectors of diagnostic data are output to the performance degradation assessment and diagnosis module 12, and the feature vectors of training data Output to the model training module 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com