Conductive slip-ring dynamic contact resistance measuring tool

A technology of dynamic contact resistance and conductive slip rings, which is applied in measuring devices, measuring electrical variables, measuring resistance/reactance/impedance, etc., can solve problems such as inability to monitor changes in loop resistance and non-stationary resistance measurement points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

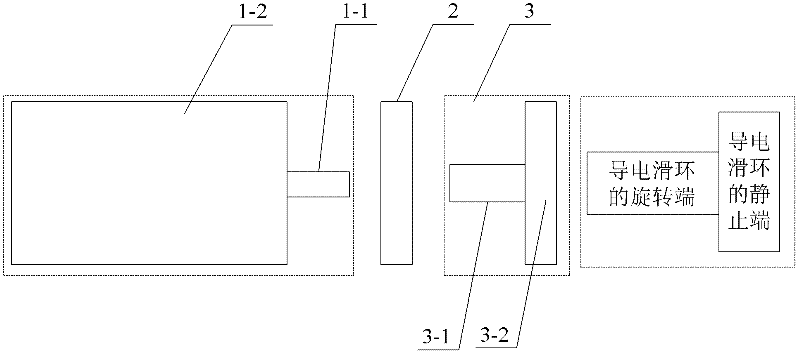

[0022] Specific implementation mode one: the following combination Figure 1 to Figure 3 Describe this embodiment, the conductive slip ring dynamic contact resistance measuring tool of this embodiment, it includes a rotating device, it also includes a static crimping device 2 and a rotary crimping device 3,

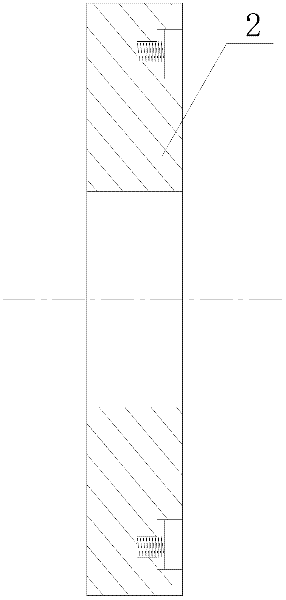

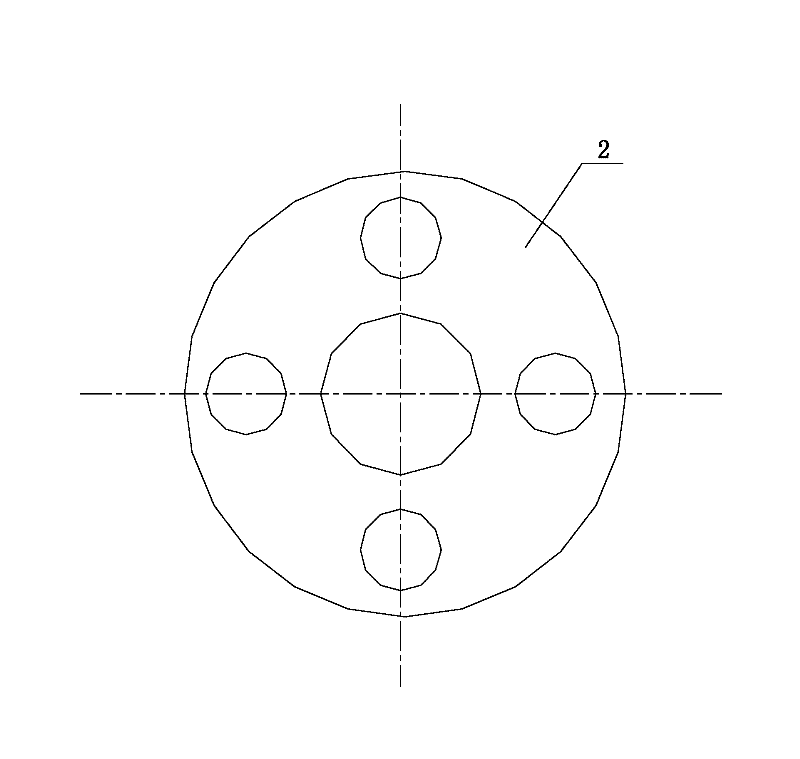

[0023] The static crimping device 2 is a disc with a central through hole. On one side of the static crimping device 2, a plurality of circular grooves are evenly distributed along the circumferential direction, and each circular groove is provided with a spring and a brass pressing device. Connecting block, the groove bottom surface of the circular groove is fixedly connected with one end of the spring, and the other end of the spring is fixedly connected with one end of the brass crimping block;

[0024] The rotary crimping device 3 is composed of a concentrically connected cylinder 3-1 and a disc 3-2, and the center of the disc 3-2 corresponding to the cylinder 3-1 has...

specific Embodiment approach 2

[0030] Embodiment 2: This embodiment is a further description of Embodiment 1. Both the static crimping device 2 and the rotary crimping device 3 in this embodiment are made of brass.

[0031] Brass is used to prepare the static crimping device 2 and the rotary crimping device 3, and since the brass is relatively soft, the tight connection of the entire tooling can be realized.

specific Embodiment approach 3

[0032] Embodiment 3: This embodiment is a further description of Embodiment 1 or 2. There are four circular grooves on one side of the static crimping device 2 .

[0033] Four circular grooves are used to embed the soft brass crimping block that provides friction and the spring that pushes the soft brass crimping block. After the wires, connect them together as a test point.

[0034] Through experiments, in the present invention, since the contact resistance produced by the crimping of the crimping device does not exceed 1 milliohm, the impact on the measurement results of the resistance is negligible, and the present invention cancels the slip ring through the friction of the crimping device The movement of the rotating end converts the rotating measuring point into a stationary measuring point. When the rotating device drives the slip ring to rotate, connect the test point with the milliohm meter to detect the resistance fluctuation of any ring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com