Thin film high-temperature friction and wear testing device

A friction and wear test, high temperature technology, applied in the direction of testing wear resistance, test sample preparation, etc., can solve the problems of limited heating temperature, large energy consumption, slow heating speed, etc., to achieve small thermal influence, high power density, The effect of high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

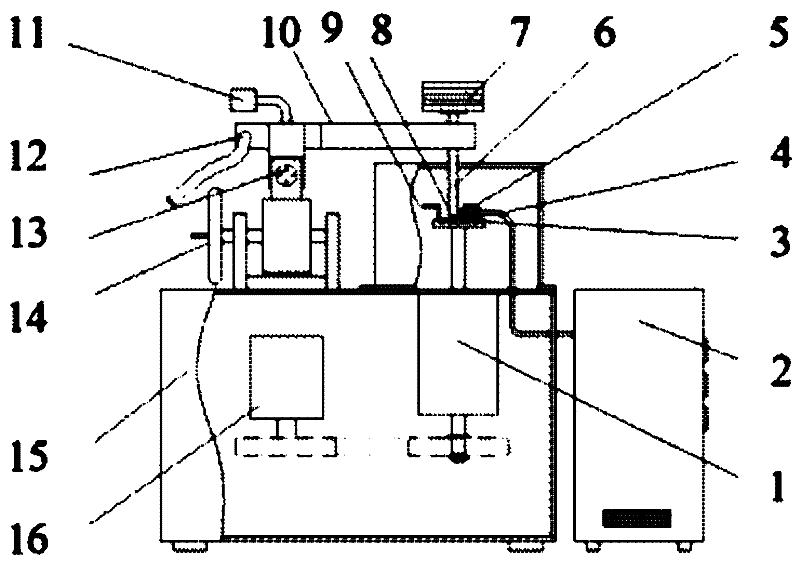

[0016] The structural principle and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] see figure 1 , a thin film high-temperature friction and wear test device, including a casing 15, a driving machine 16 is arranged in the casing 15, a moving sample disc 3 is arranged on the driving shaft 1 of the driving machine 16, and the driving shaft 1 drives the moving sample circle The disk 3 rotates, and a magnetizer 5, an induction heating coil 4, and an infrared thermometer 9 are arranged on the top of the moving sample disk 3 in a non-contact manner, and the magnetizer 5 and the induction heating coil 4 perform non-contact heating on the moving sample disk 3 , the infrared thermometer 9 measures the surface temperature of the moving sample disk 3, and a fixed sample 8 is arranged in contact with the top of the moving sample disk 3, and the fixed sample 8 is fixed by the fixed sample clamp 6, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com