Method for measuring emissivity of infrared temperature measurement target body

An infrared temperature measurement and measurement method technology, applied in the field of instrument measurement, can solve the problems of low thermocouple accuracy, lag in temperature data comparison, no measurement method, etc., and achieves the effects of low equipment cost, easy implementation and simple measurement method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] A method for measuring emissivity of an infrared temperature measurement target, comprising the following steps:

[0033] (1) Selection of infrared radiation thermometer: In a standard thermal laboratory with constant temperature and humidity, select an integral single-color or two-color infrared radiation thermometer that has passed the verification of the blackbody furnace as the infrared radiation characteristic of the measured object Test the main equipment.

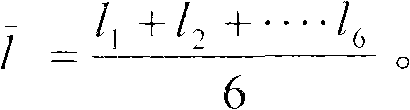

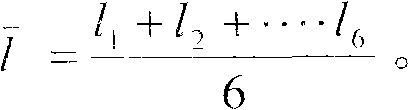

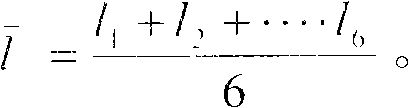

[0034] in:

[0035] The temperature range of the blackbody furnace is 300-1700°C, the accuracy is ±0.25%, and the effective emissivity is 0.98; the temperature range of the integral single-color or two-color infrared radiation thermometer is 700-1600°C, and its accuracy is better than ± 0.75% FS; repetition accuracy is better than ±0.3% FS; single-color emissivity range is 0.1-1.0, step size is better than 0.01; two-color slope range is 0.85-1.15, step size is better than 0.001; where FS is infrared radiation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com