High-precision spherical hinge structure for parallel machine tools

A high-precision, spherical joint technology, applied in the direction of couplings, mechanical equipment, elastic couplings, etc., can solve the problems of high machining accuracy and difficult installation, and achieve high tensile strength, convenient installation and debugging, and unstructured complex effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

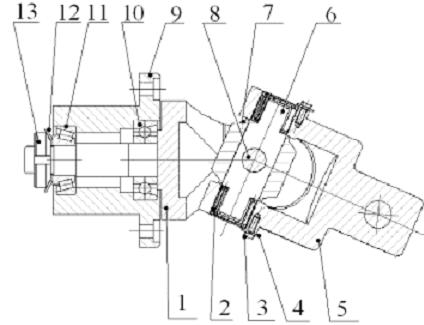

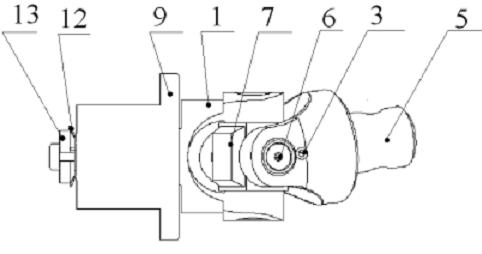

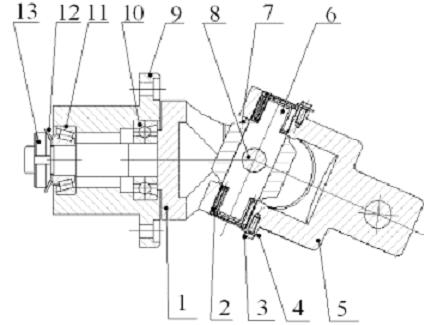

[0011] The invention is a high-precision spherical joint structure for a parallel machine tool, such as figure 1 , figure 2 As shown, it includes lock nuts, washers, ball hinge lower fork bearing seats, cylindrical pins, cross blocks, pin shafts, ball hinge upper forks, large washers, screws, needle bearings and ball hinge lower forks, etc.; the ball hinge The upper fork 5 takes the pin shaft 6 located in the cross block 7 as the rotating shaft, and the cylindrical pin 8 is inserted horizontally in the pin shaft 6 as the rotating shaft of the ball hinge lower fork 1, and the ball hinge lower fork 1 passes through the lock nut 13 and two pairs of bearings 10 , 11 cooperates with the lower fork bearing seat 9 of the ball hinge. This hinge structure can be used instead of the ball hinge in the parallel machine tool. Compared with the traditional ball hinge, it has a large independent rotation angle range, high tensile strength, convenient installation and debugging, and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com