Lattice type single-row reinforcement T-shaped cross section concrete column and construction method thereof

A technology of concrete columns and lattice structures, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of weak earthquake resistance, poor thermal insulation performance, poor integrity of houses in villages and towns, etc., and achieve simple construction, less steel reinforcement, Effects of Improving the Seismic Ductility of Columns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

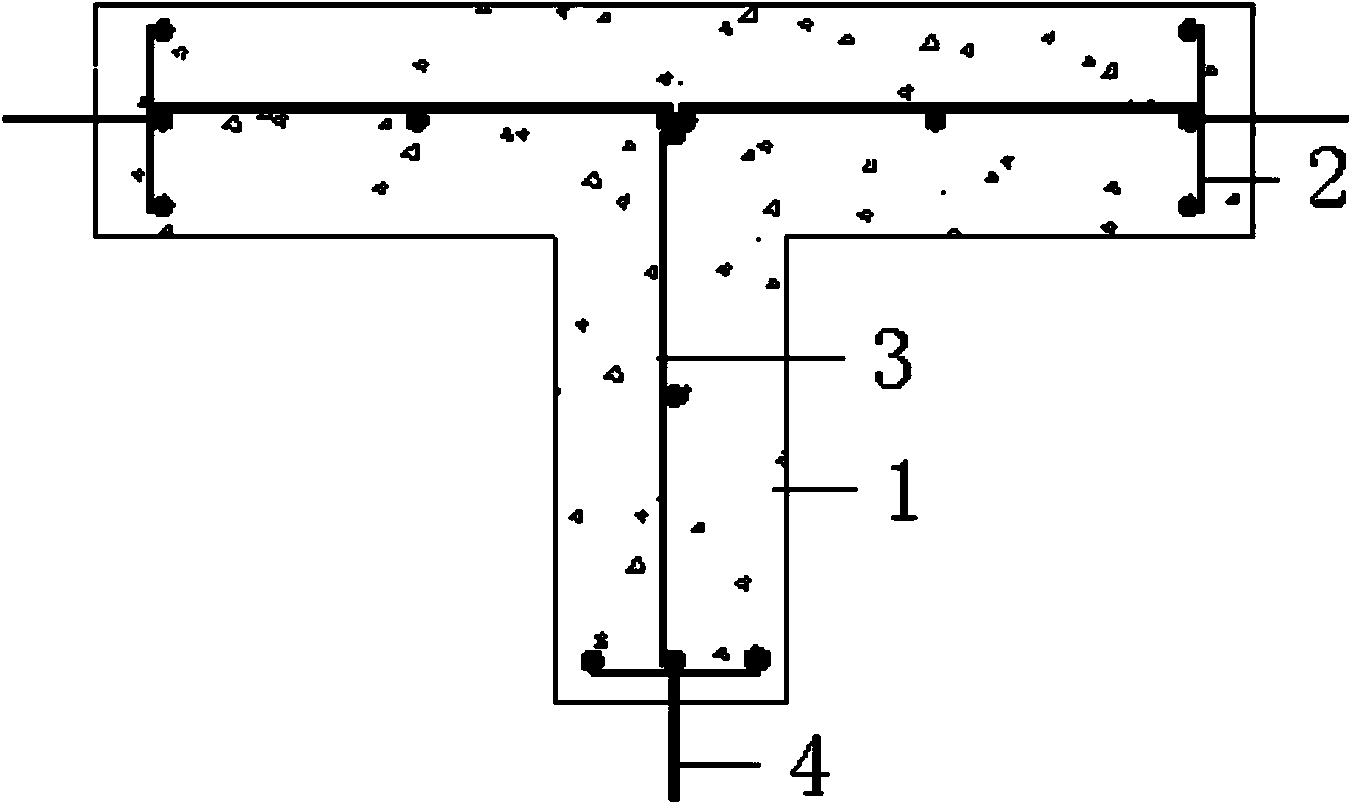

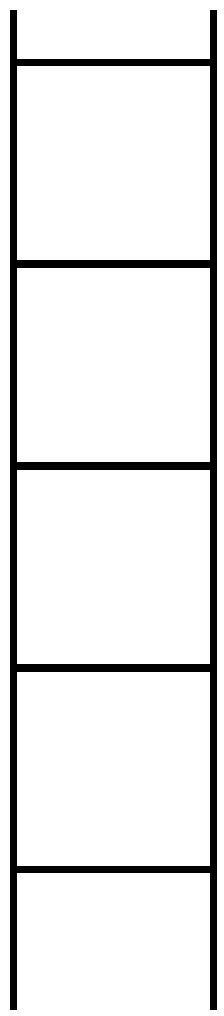

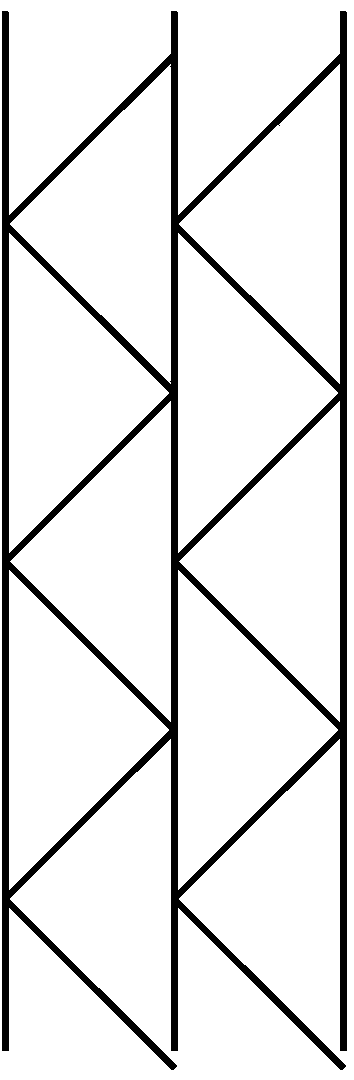

[0030] Such as Figure 1 to Figure 5 The lattice-type single-row reinforcement T-shaped concrete column is composed of concrete 1, ladder grid reinforcement mesh 2, lattice single-row reinforcement mesh 3, and tie reinforcement 4. It is characterized in that: the T-shaped The column steel skeleton is T-shaped, and three pieces of lattice single-row reinforcement mesh 3 are welded into T-shaped three limbs; The plane of the single-row reinforcing mesh 3 passes through the central axis of the ladder-like reinforcing mesh 2; the ladder-like reinforcing mesh 2 is welded into a ladder-like shape by two vertical reinforcing bars and several transverse horizontal reinforcing bars; The reinforcing mesh 3 is located on the center line of the concrete column section, and is composed of vertical steel bars and W-shaped oblique web bars between the vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com