Method and device for adjusting linear density of glass fiber through correcting bushing temperature in real-time manner

A technology of glass fiber and linear density, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of keeping unchanged, easy aging of temperature sensor, influence of temperature sensor accuracy, etc., and achieve the effect of optimal adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

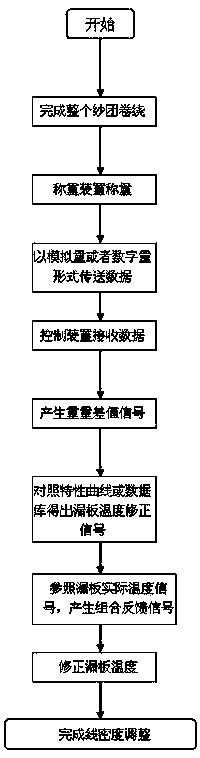

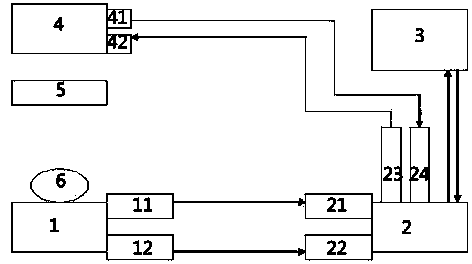

[0031] Such as figure 1 and figure 2 shown. In this embodiment, the method for adjusting the glass fiber linear density by correcting the bushing temperature in real time comprises the following steps:

[0032] a. Let the glass liquid pass through the small holes formed on the bushing to form glass fibers, and wind a certain length of glass fibers with rotating winding wires to make yarn balls;

[0033] b. Generate a signal representing the weight of the yarn ball;

[0034] c. Responding to the bobbin weight signal, referring to the set weight value, generating a weight difference signal indicating the degree of difference between the bobbin weight and the set weight;

[0035] d. Respond to the weight differenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com