Method and device for regulating linear density of glass fiber through correcting drawing flow in real time

A glass fiber and linear density technology, which is applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of temperature sensor accuracy influence, temperature sensor is easy to age, and glass fiber linear density cannot be guaranteed to remain unchanged, so as to achieve accurate adjustment and accurate The effect of drawing flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

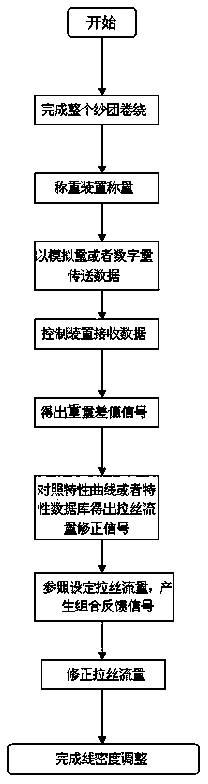

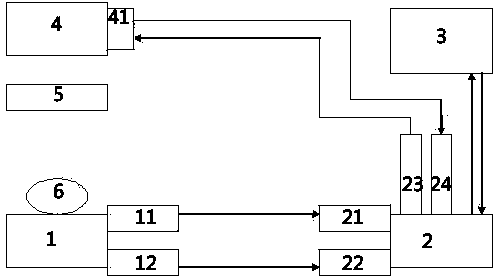

[0026] Such as figure 1 and figure 2 As shown, the method for adjusting the linear density of glass fibers by correcting the drawing flow in real time in this embodiment is characterized in that it includes the following steps:

[0027] a. Make the glass liquid pass through the small hole formed on the bushing 5 to form glass fibers, and wind the glass fibers with rotating winding wires to make yarn clusters 6;

[0028] b, generating a signal representing the weight of the yarn cluster 6;

[0029] c. In response to the weight signal of the yarn cluster 6, referring to the set weight value, a weight difference signal indicating the degree of difference between the weight of the yarn cluster 6 and the set weight is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com