Automatic outlet pressure regulating device for variable sprayer

An outlet pressure, automatic adjustment technology, applied in the direction of spray devices, spray devices with movable outlets, etc., can solve the problems of poor spray uniformity of variable nozzles, and achieve the effect of improving spray uniformity, reliable operation, and strong operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

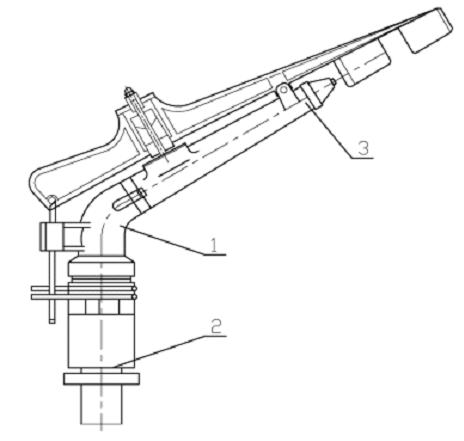

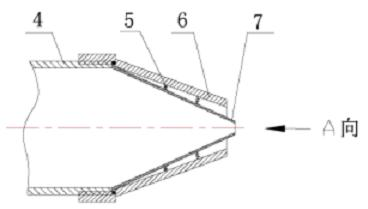

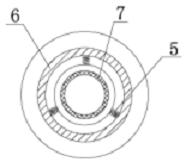

[0014] Such as figure 1 , 2 , 3, the present invention includes a nozzle 1, an inlet pressure regulator 2, an outlet pressure automatic regulator 3, a nozzle 4, a spring 5, a nozzle 6, and an elastic flow channel 7. The elastic flow channel 7 is a shrinkable conical shape, and its outlet diameter is 1 / 5 to 1 / 3 times of the inlet diameter. Sealing means. The nozzle 6 is an open conical cylinder, the bottom of the conical cylinder of the nozzle 6 is fixedly connected to one end of the nozzle 4; the elastic flow channel 7 is built inside the nozzle 6, and the built-in elastic flow channel 7 is connected to the inner wall of the nozzle 6 by a spring 5 , the spring 5 is located at 1 / 3 and 2 / 3 of the length of the nozzle 6, the spring 5 and the nozzle 6 are processed as one, and three springs 5 are evenly arranged on the cross section of each nozzle 6, the purpose of which is to make the elastic flow The stress of road 7 compression springs 5 is even. The elastic flow channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com