Tobacco shred drying method

A drying method and shredded tobacco technology, applied in tobacco, tobacco preparation, application, etc., can solve the problems of loss of beneficial chemical components in shredded tobacco, and achieve the effects of good quality characteristics, economical use of heat energy, and low phase equilibrium temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

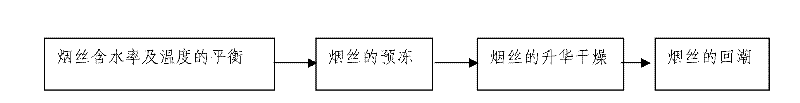

Method used

Image

Examples

Embodiment 1

[0019] The raw material is 2009 C2F tobacco leaves. The specific process steps are: ① balance of moisture content and temperature of cut tobacco: balance the moisture content of cut tobacco to 21%, and balance the temperature to 15°C; ② pre-freezing of cut tobacco: balance the balanced The shredded tobacco is quickly frozen to -40°C at a cooling rate of -0.6°C / min, and kept for 0.5h; ③Sublimation drying of shredded tobacco: put the pre-frozen shredded tobacco into a vacuum chamber for drying, where the absolute pressure in the vacuum chamber is 60Pa, heat The plate temperature is 35°C, and the time is 2 hours; ④Remoisture of shredded tobacco: Pass the freeze-dried shredded tobacco through the moisture resurgence equipment, and rehydrate the shredded tobacco until the moisture content of the shredded tobacco is 12.5%.

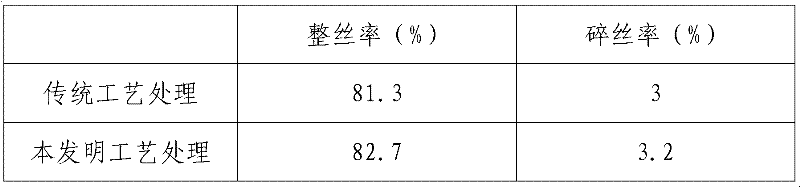

[0020] Table 1 shows the comparison of shredded tobacco structure between the conventional process and the process of the present invention, the comparison of sh...

Embodiment 2

[0029] The raw material is 2010 B2F tobacco leaves. The specific process steps are: ① balance of moisture content and temperature of cut tobacco: balance the moisture content of cut tobacco to 23%, and balance the temperature to 20°C; ② pre-freezing of cut tobacco: balance the balanced The shredded tobacco is quickly frozen to -40°C at a cooling rate of -0.8°C / min, and kept for 1.2h; ③Sublimation drying of shredded tobacco: put the pre-frozen shredded tobacco into a vacuum chamber for drying, where the absolute pressure in the vacuum chamber is 55Pa, and heat The temperature of the board is 35°C, and the time is 3 hours; ④Remoisture of shredded tobacco: Pass the freeze-dried shredded tobacco through a moisture resurgence device, and regain moisture until the moisture content of shredded tobacco is 12.0%.

[0030] Table 4 shows the comparison of shredded tobacco structure between the traditional process and the process of the present invention, the comparison of shredded tobacco...

Embodiment 3

[0038] Repeat Example 1, with the following differences: the moisture content of cut tobacco is balanced to 20%, and the temperature is balanced to 10°C; the balanced tobacco is quickly frozen to -35°C at a cooling rate of -0.9°C / min, and Keep for 1.5h; the absolute pressure in the vacuum chamber is 70Pa, the temperature of the heating plate is 20°C, and the time is 2h.

[0039] Table 7 shows the comparison of shredded tobacco structure between the traditional process and the process of the present invention, the comparison of shredded tobacco filling value is shown in Table 8, and the sensory quality evaluation of cigarettes after rolling is shown in Table 9.

[0040] Table 7 Shredded Tobacco Structure Comparison Table

[0041]

[0042] Table 8 Comparison table of shredded tobacco filling value

[0043] Filling value (cm 3 / g)

traditional process

4.7

Process treatment of the present invention

4.5

[0044] Table 9 Sensory Qual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com