Mixed enzyme for preparing instant rice and application of same

A technology of instant rice and mixed enzymes, applied in the fields of application, food preparation, food science, etc., to achieve the effects of simple and easy optimization process, good stability, good fast food performance and anti-retrogradation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

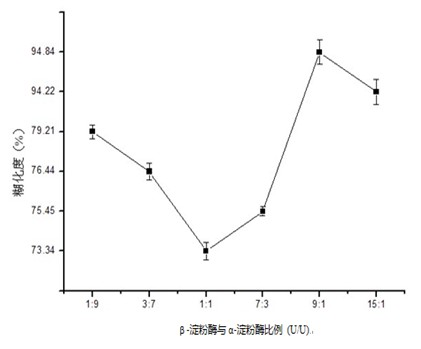

[0032] Example 1 Effect of the Ratio of β-amylase and α-amylase on the Gelatinization Degree of Instant Rice

[0033] Method: Add 1.4 times the mass ratio of water to the washed rice, soak it in a constant temperature water bath at 50°C for 30 minutes, and cook the rice in an electric steam sterilizer for 12 minutes at a temperature of 116°C. Divided into experimental groups 1-6, each group sprayed 10mL of mixed enzyme liquid in the cooked rice, among which the experimental group 1 mixed enzyme was composed of 15U β-amylase and 1U α-amylase based on the enzyme activity of the rice. 2 groups of mixed enzymes are composed of 9Uβ-amylase and 1Uα-amylase based on the enzyme activity of the rice, the experimental group 3 mixed enzymes are composed of 5Uβ-amylase and 1Uα-amylase based on the enzyme activity of the rice, and the experimental group 4 The mixed enzyme is composed of 1U β-amylase and 1U α-amylase based on the enzyme activity of the rice, the experimental 5 groups of m...

Embodiment 2

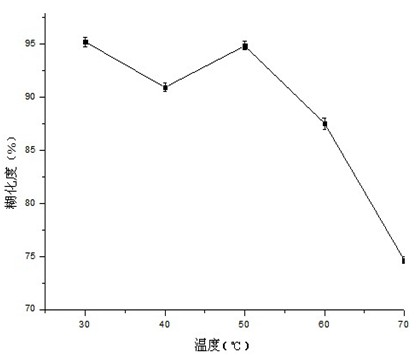

[0037] Embodiment 2, the influence of enzyme action temperature on the gelatinization degree of instant rice

[0038] Method: Add 1.4 times (mass ratio) of water to the washed rice, soak in a constant temperature water bath at 50°C for 30 minutes, and cook the rice in an electric steam sterilizer for 12 minutes at a temperature of 116°C. Spray 10mL of mixed enzyme solution in the cooked rice again, the mixed enzyme is composed of 9Uβ-amylase and 1Uα-amylase in terms of the enzyme activity of the rice, and the action temperature is 30°C, 40°C, 50°C, 60°C, respectively. ℃, 70 ℃, and the action time is 36 minutes, the instant rice samples are prepared, and the gelatinization degree of the instant rice is calculated.

[0039] The result is as figure 2 As shown, when the enzyme activity ratio of β-amylase and α-amylase solution is 9:1, the enzyme action time is 36 minutes, and the enzyme action temperature rises from 30°C to 50°C, the gelatinization degree of instant rice shows...

Embodiment 3

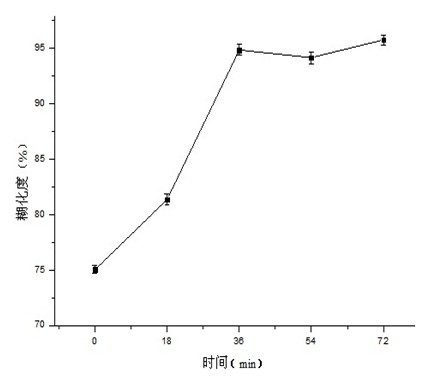

[0040] Embodiment 3, the influence of enzyme action time on the gelatinization degree of instant rice

[0041]Method: Add 1.4 times (mass ratio) of water to the washed rice, soak in a constant temperature water bath at 50°C for 30 minutes, and cook the rice in an electric steam sterilizer for 12 minutes at a temperature of 116°C. Then spray 10mL of mixed enzyme with a concentration ratio (β-amylase / α-amylase) of 9:1 in the cooked rice, the enzyme action temperature is 50°C, and the action time is 0min, 18min, 36min, 54min, 72min When , instant rice samples were prepared, and the gelatinization degree of instant rice was calculated.

[0042] The result is as image 3 As shown, when the enzyme activity ratio of β-amylase and α-amylase solution is 9:1 (U / U), and the enzyme action temperature is 50°C, in a short period of time (0-36min), with the extension of time , the gelatinization degree of instant rice showed a significant increase trend. After 36 minutes, the value of g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com