Shutter with large aperture

It is a technology of light and shutter, which is applied in the direction of shutter, optics, camera, etc. It can solve the problems of no practical operability, cumbersome overall structure, and low space utilization rate, and achieve good rigidity, simple structure, easy overall installation and The effect of disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

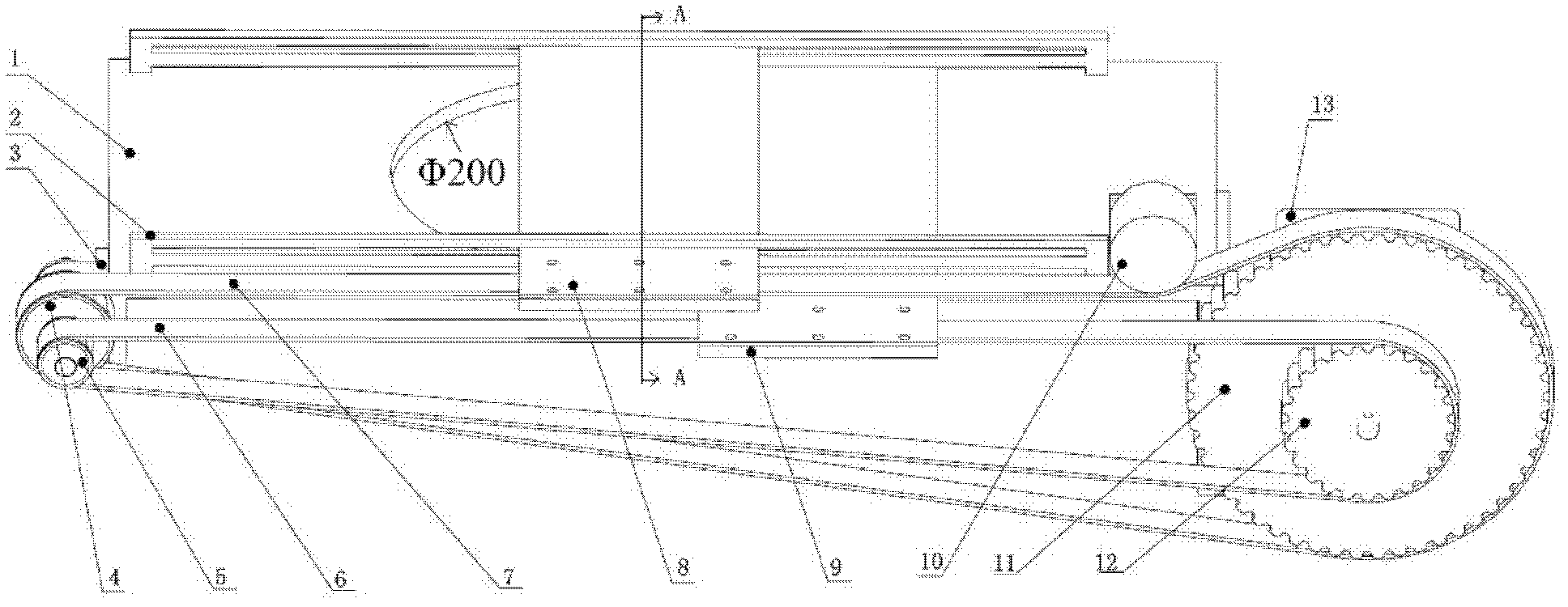

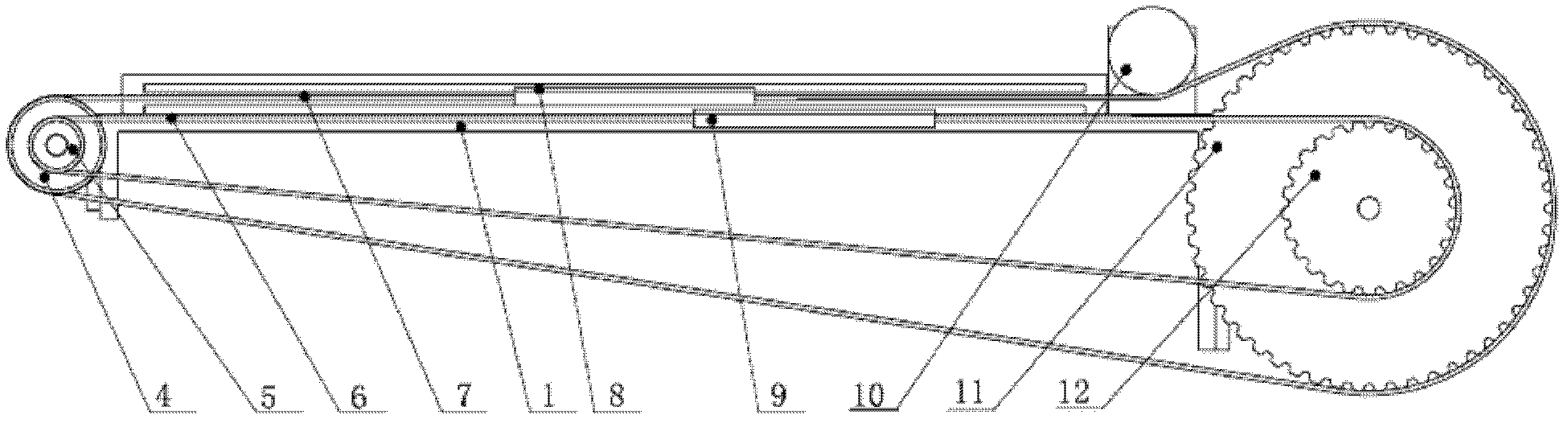

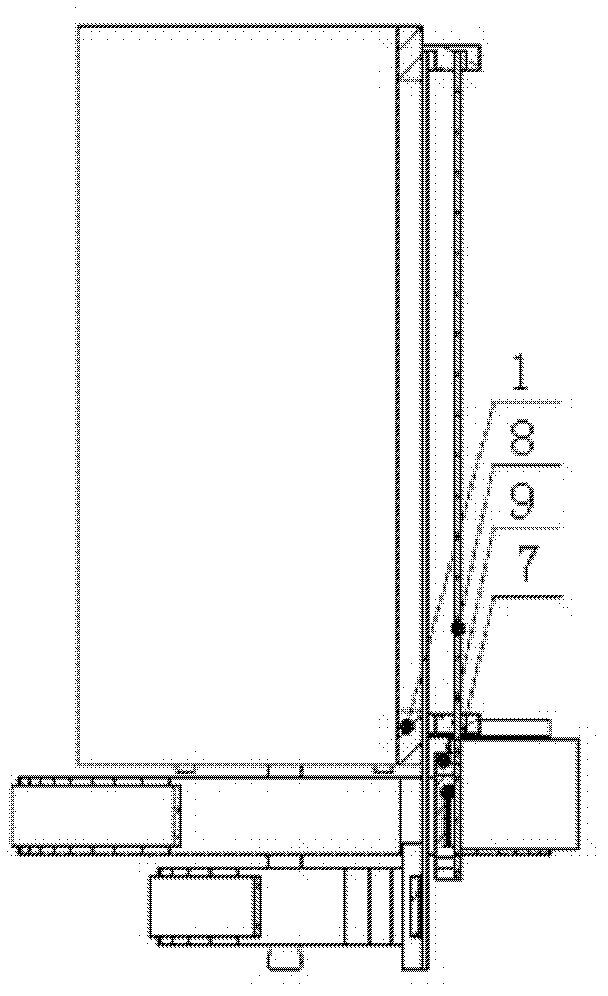

[0018] like figure 1 As shown, including base 1 is the base of the whole mechanism, 1 motor base 13, 1 driven wheel base 3, 1 tensioning wheel seat 10, 1 driving wheel one 11, one driving wheel two 12, 1 slave Driving wheel one 4, one driven wheel two 5, one pair of synchronous transmission one 7, one pair of synchronous belt two 6 are installed on one side of the base. Motor base 13 and driven wheel base 3 are installed on base 1 left and right sides, driving wheel one 11 and driving wheel two 12 concentric shafts are fixed on the motor base 13, driven wheel one 4 and driven wheel two 5 concentric shafts are fixed on slave On the driving wheel base 3, adjust the motor base 13 and the waist hole on the driven wheel base 3 to ensure that the upper part of the synchronous conveyor belt 26 is connected to the pulley and the upper part is horizontal and at the same level as the upper surface of the base 1. Here, in order to reduce the quality of the shutter, the active The first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com