Torsional spring fatigue tester

A technology of fatigue testing machine and testing machine, which is applied in the direction of testing the strength of materials, measuring devices, instruments, etc. by applying repeated force/pulsation force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

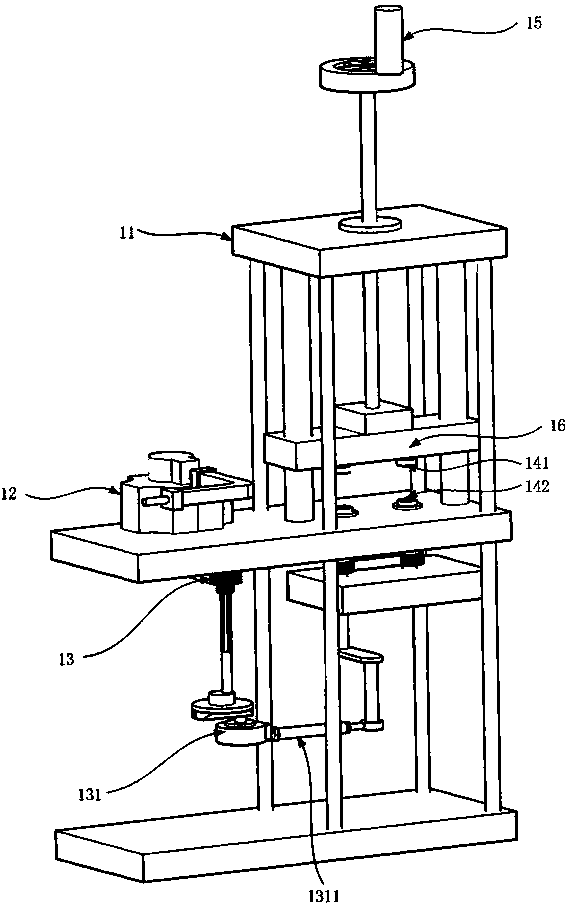

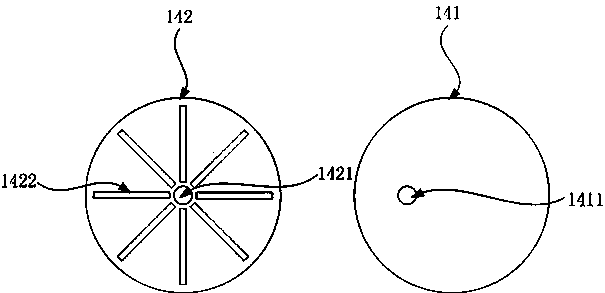

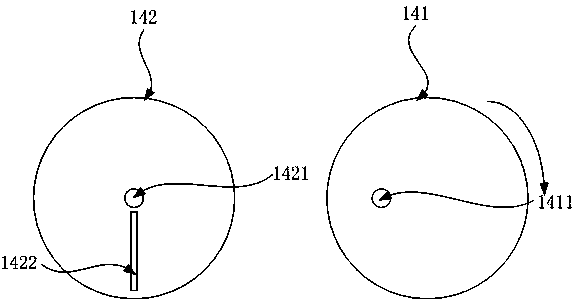

[0023] like Figure 1 to Figure 3 Shown, a kind of torsion spring fatigue testing machine, this testing machine comprises main body 11, motor 12, transmission mechanism 13, torsion spring fixture, lifting table 16 and rotary handle 15, and this main body 11 provides an installation foundation, motor 12, lifting table 16 and the torsion spring fixture are respectively fixedly connected to the main body 11; the motor 12 provides the driving force of the test, and the transmission mechanism 13 transmits the driving force. The moving direction of the lifting platform 16 is perpendicular to the swing plane of the torsion spring base 142 , and the torsion spring top base 141 is fixed on the lifting platform 16 . The torsion spring top seat 141 is arranged on the lifting platform 16, so that the distance between the torsion spring top seat 141 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com