Annular ejector for high altitude environment simulation test

An environmental simulation test and ejector technology, which is used in the testing of instruments, engines, and testing of machine/structural components, can solve the problems of experimental research, high test costs, and many connecting pipes, etc., to improve work efficiency, The effect of reducing trial costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

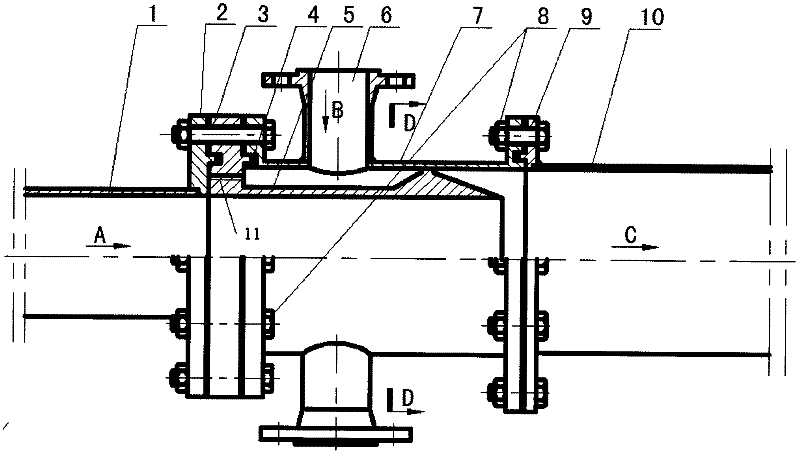

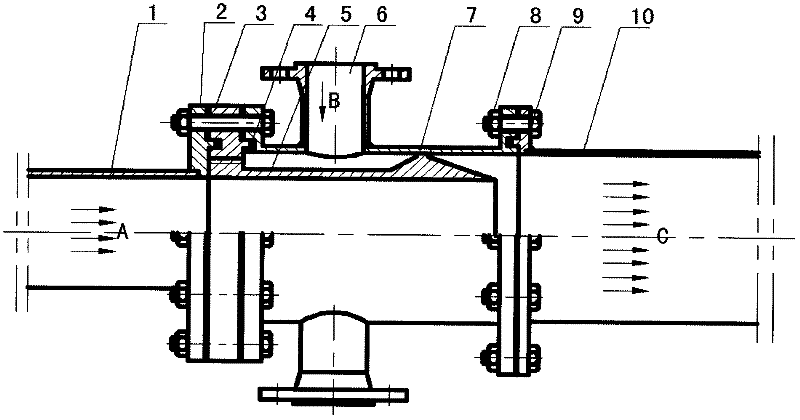

[0018] The present invention will now be further described in conjunction with the embodiments and drawings:

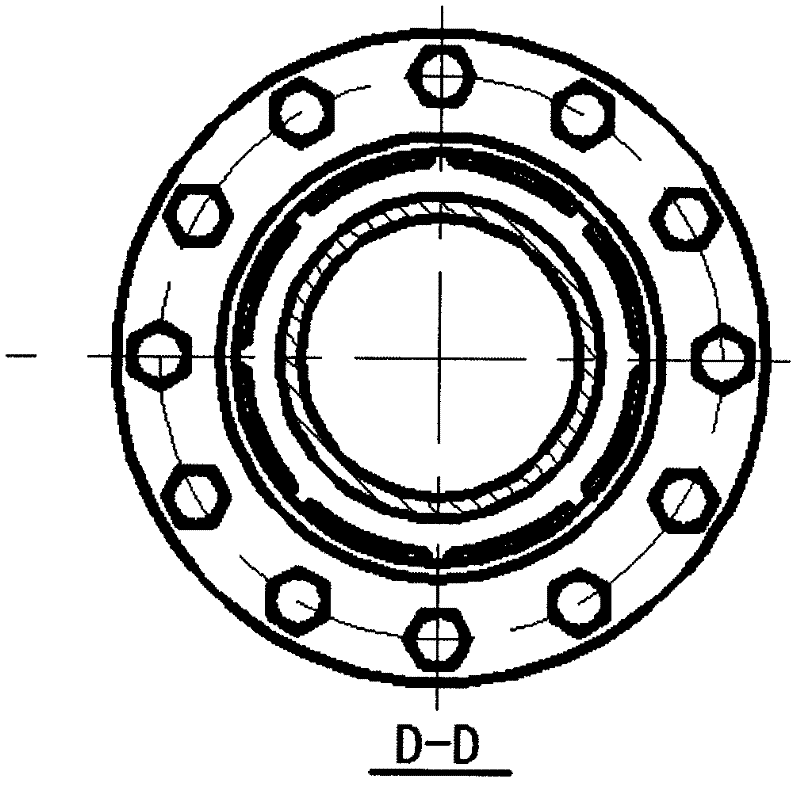

[0019] Such as figure 1 As shown, the ejection nozzle 5 and the adapter flange 3 are connected by pipe threads, and the ejection nozzle 5 is placed in the ejector outer cylinder 7; the two ends of the adapter flange 3 are respectively connected to the ejector outer cylinder 7 and the incoming flow. The connecting flange I 2 of the ejector pipe 1 is fixed by the bolt assembly 8, and the boss of each connecting surface is provided with a seal 4; the mixing pipe 10 is fixed with the ejector outer cylinder 7 through the connecting flange II 9 by the bolt assembly 8 . The outer tube 7 of the ejector has an inner diameter of 70-200mm and a length of 150-300mm. The ejector gas inlet pipes 6 are arranged on both sides, and the diameter of the inlet pipe is 25-50mm.

[0020] According to the test requirements, you can change the inner diameter of the ejection nozzle 5 at 50~150mm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com