Laser-probe-array-based three-dimensional measurement method and device

A laser probe and three-dimensional measurement technology, applied in the field of three-dimensional measurement, can solve the problems of long processing time, inability to perform stereo matching, interference by laser noise and vibration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

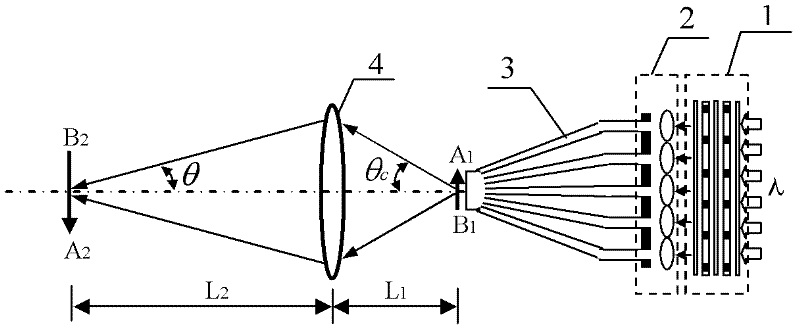

[0057] A three-dimensional measurement method based on a laser probe array includes the following steps:

[0058] Step 1. Set the optical center of the optical lens of the two-dimensional camera as the origin of coordinates. The optical axis of the optical lens of the two-dimensional camera is the Z axis, the X axis is perpendicular to the Z axis, the X axis and the Z axis plane is a horizontal plane, and the Y axis is perpendicular to X. Axis Z-axis plane; set the first laser probe generator on the X axis, the optical axis of the first laser probe generator is parallel to the Z axis, the two-dimensional camera monitors the laser probe emitted by the first laser probe generator The reflection on the surface of the object under test, where the first laser probe generator is a digital optical phase conjugate device or a holographic reconstruction device;

[0059] Step 2. Set the predetermined focus point of the laser probe array emitted by the first laser probe generator on the prede...

Embodiment 2

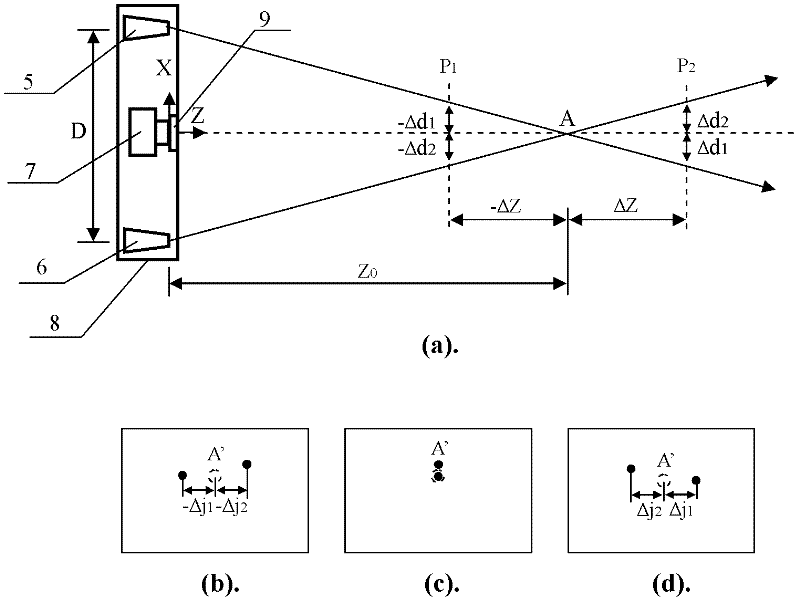

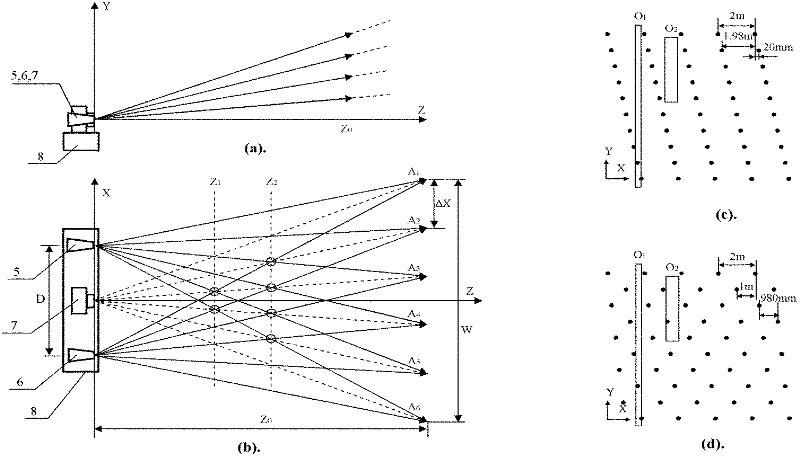

[0081] Such as figure 2 , image 3 As shown, a three-dimensional measurement device based on a laser probe array includes a first laser probe generator 5, a second laser probe generator 6, a first two-dimensional camera 7 and a first holder 8, and a first laser probe The needle generator 5, the first two-dimensional camera 7, and the second laser probe generator 6 are fixed on the first bracket 8 at an equal distance in turn. The optical axis of the first laser probe generator 5 and the second laser probe generator The optical axis of 6 and the optical axis of the first two-dimensional camera 7 are parallel to each other and are located on the same plane. The connection between the optical centers of the first laser probe generator 5 and the second laser probe generator 6 is perpendicular to their optical axes , The optical center of the lens of the first two-dimensional camera 7 is located on the line connecting the optical centers of the first laser probe generator 5 and the ...

Embodiment 3

[0110] Such as Figure 4 , Figure 5 As shown, a three-dimensional measurement device based on a laser probe array includes a third laser probe generator 10, a fourth laser probe generator 11, a second two-dimensional camera 13, a second movable support 12 and a third The movable support 14, the third laser probe generator 10 and the fourth laser probe generator 11 are fixed on the second movable support 12, the third laser probe generator 10 and the fourth laser probe generator 11 The optical axes are parallel to each other, and the connection of their optical centers is perpendicular to their optical axis. The second two-dimensional camera 13 is fixed on the third movable support 14, the second movable support 12 and the third movable support 14 Both are provided for aligning the optical axis of the second two-dimensional camera 13, the optical axis of the third laser probe generator 10, and the optical axis of the fourth laser probe generator 11 on the same plane and parallel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com