Detecting assembly for shaft piece

A technology for detecting tooling and shaft parts, applied in angle/taper measurement, etc., can solve problems such as difficult operation and difficulty, achieve high accuracy, fast completion speed, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

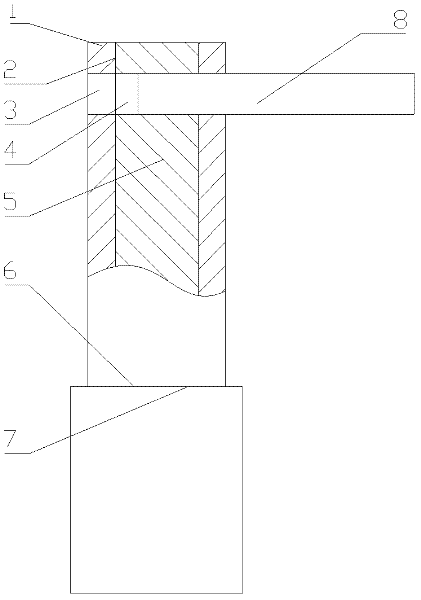

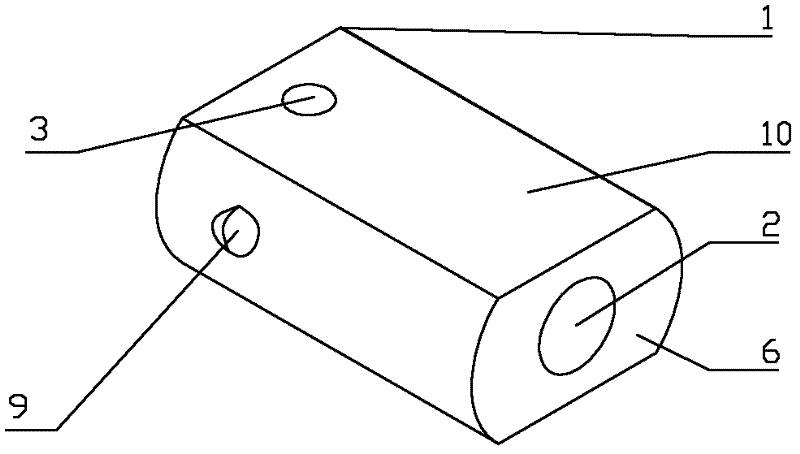

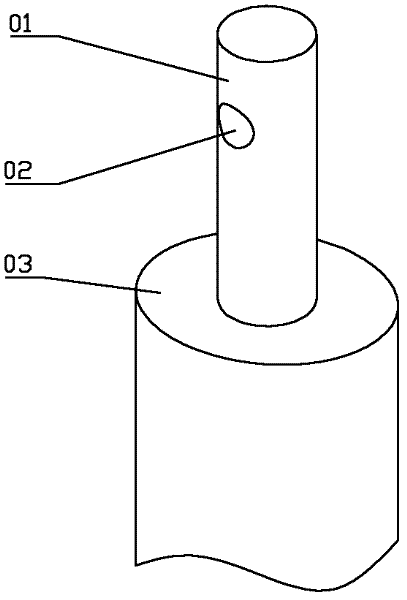

[0015] Such as figure 1 , figure 2 The structure schematic diagram of the embodiment of the present invention is shown, a shaft detection tool, including a body 1 and a push rod 8, the body 1 is vertically provided with a shaft hole 2, and the shaft hole is matched with the first step section and does not Radial swing occurs, after the body is inserted into the first step section, the lower bottom surface 6 of the body designed as a plane falls on the step surface 7 between the first step section and the second step section, and the push rod 8 and the connecting hole 4 Cooperate, and no radial swing occurs, the axis of the rod hole 3 intersects and is perpendicular to the axis of the shaft hole 2, that is, ensure that the axis of the rod hole and the axis of the shaft hole are in the same plane, so that the body is sleeved in the first stepped section Then, the ejector rod is penetrated along the rod hole, through the connecting hole 4, and then penetrated into the rod hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com