Multi-frame reciprocating grate

A technology of reciprocating grate and frame, applied in the direction of grate, mobile grate, lighting and heating equipment, etc., can solve problems such as affecting the normal operation of the boiler, connection failure, etc. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

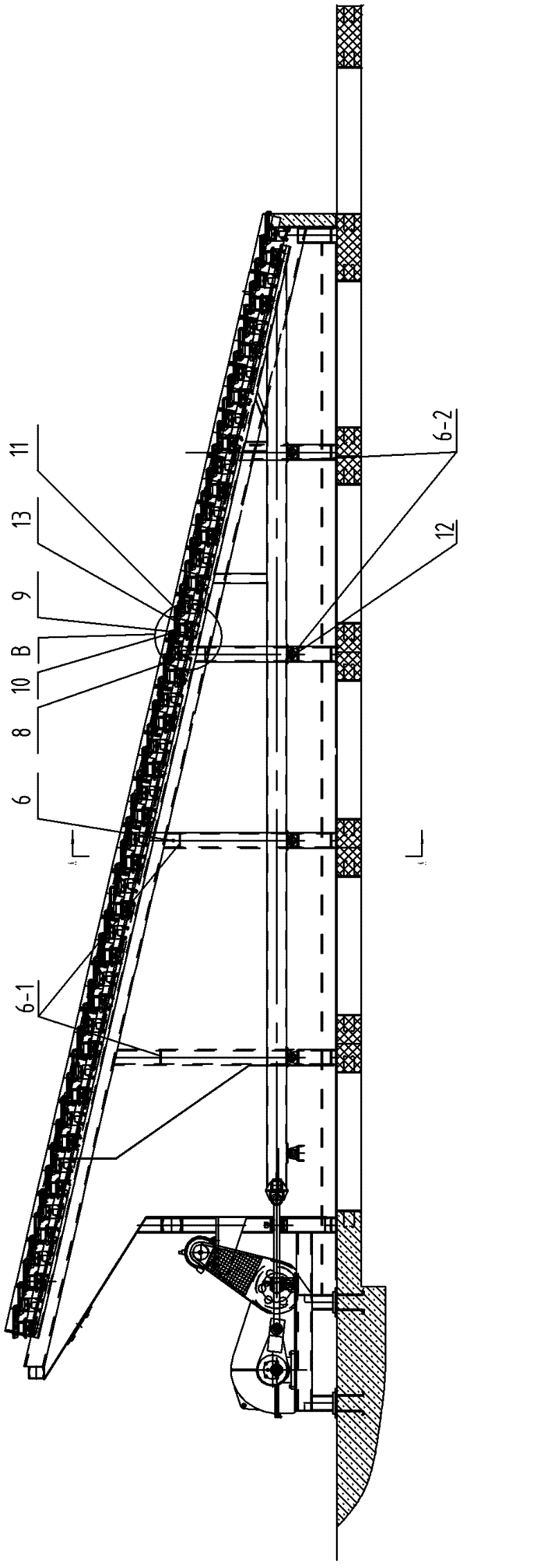

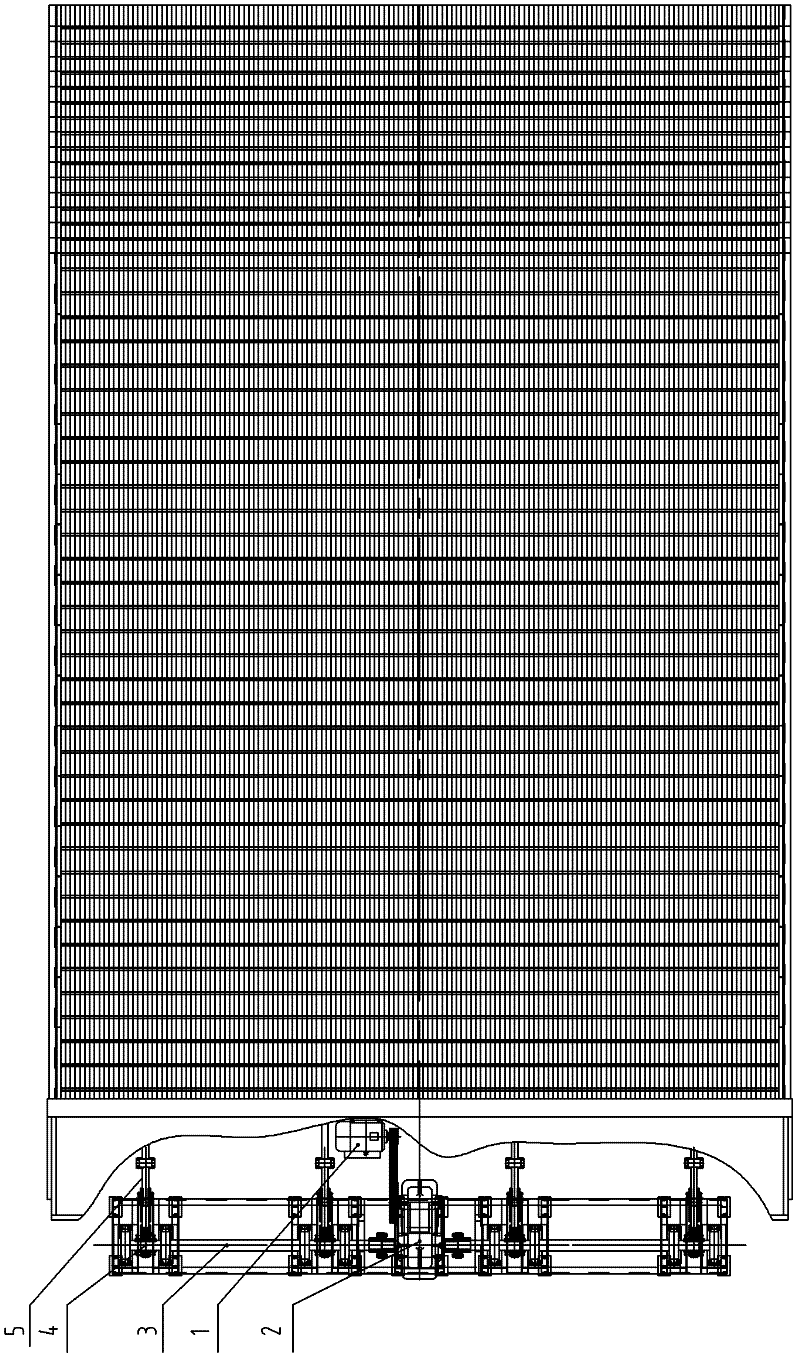

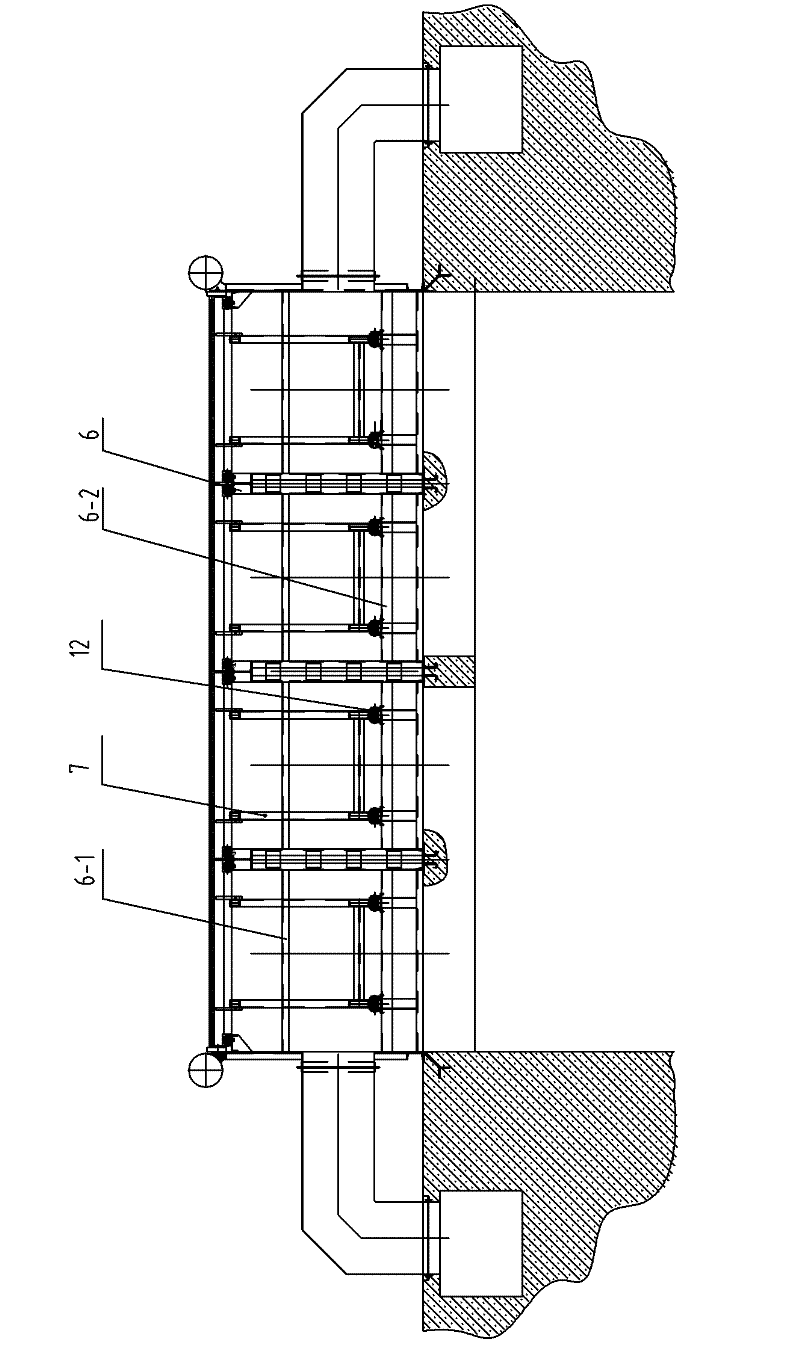

[0007] Specific implementation mode one: combine Figure 1-Figure 4 Describe this embodiment, the fire grate of this embodiment comprises motor 1, speed reducer 2, transmission shaft 3, multiple eccentric wheels 4, multiple push-pull rods 5, fixed fire grate frame 6, movable fire grate frame 7, multiple fixed Grate beam 8, multiple movable grate beams 9, multiple fixed grate pieces 10, multiple movable grate pieces 11, multiple movable grate frame rollers 12 and multiple movable grate beam rollers 13, output end of motor 1 It is connected to the input end of the reducer 2, and the output end of the reducer 2 is connected to the transmission shaft 3. The transmission shaft 3 is equipped with a plurality of eccentric wheels 4, and each eccentric wheel 4 is connected to one end of the push-pull rod 5. The push-pull rod The other end of 5 is connected to the corresponding movable grate frame 7 through transmission, and the movable grate frame 7 is arranged in the fixed grate frame...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the fixed grate frame 6 of this embodiment is set with a high front and a low slope at the rear, and the inclination angle is 11°-15°. The use of low-quality coal requires a thick coal seam, and the grate can be guaranteed at an angle of 11°-15°. The reciprocating grate transports a thicker coal seam, and the coal seam has a certain tumbling ability during the movement; the double roller structure decomposes the gravity of the movable grate frame and the movable grate beam to reduce local wear. When a certain roller is worn out, the supported part will sink, and at this moment, another set of rollers can prevent the sinking. Therefore, the structure has the advantages of small running resistance and low failure rate. Other components and connections are the same as those in the first embodiment. Other components and connections are the same as those in the first embodiment.

[0009]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com