Installing structure of guardrail lamp

A technology for installation structures and guardrail lights, which is applied in the direction of lighting devices, fixed lighting devices, lighting device components, etc., can solve problems such as inability to cooperate with installation, rework and redo, and inaccurate positioning holes, so as to avoid installation deviation, Accurate positioning, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

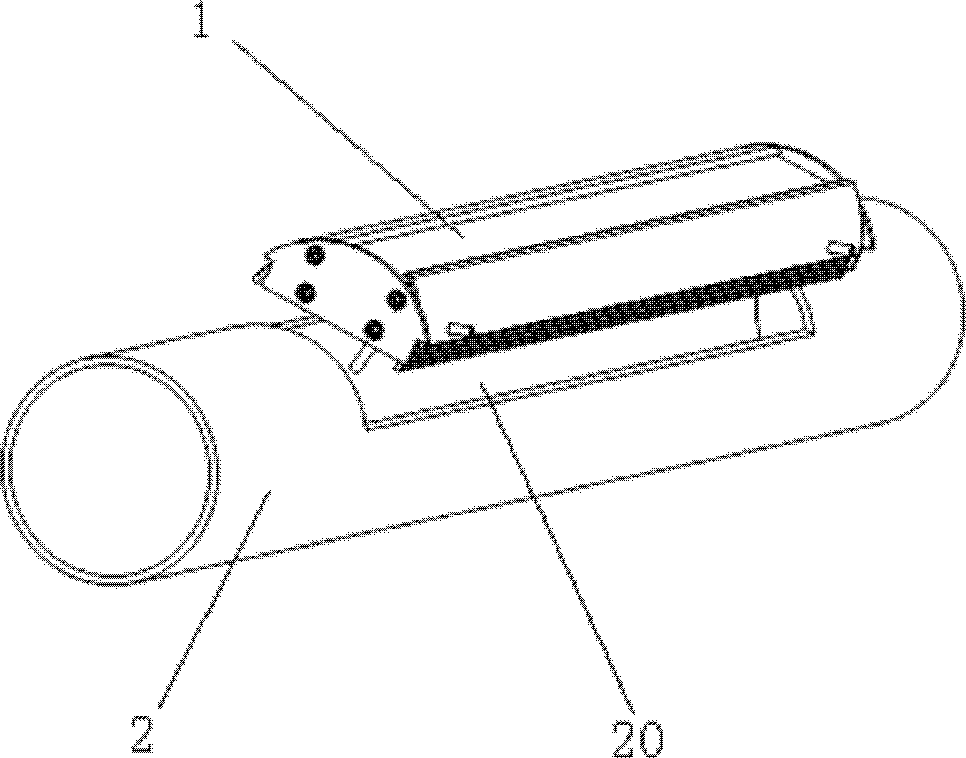

[0023] Such as figure 1 As shown, the guardrail light installation structure disclosed in the present invention includes a lamp 1, which is installed in a long slot 20 opened on the cylindrical wall of the cylindrical guardrail 2.

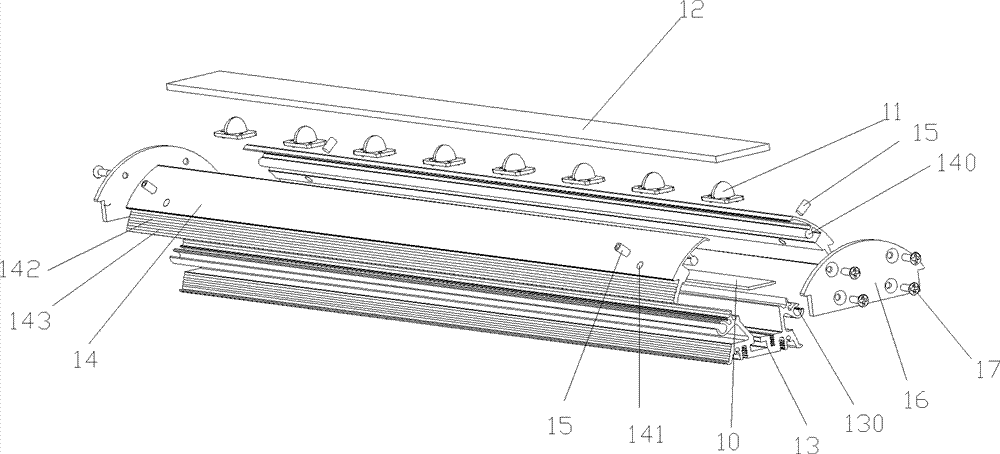

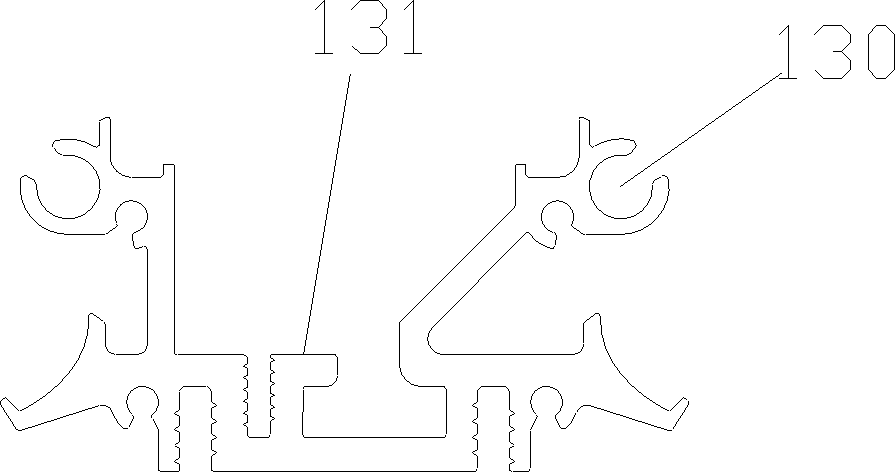

[0024] Such as Figure 2 ~ Figure 6 As shown, the lamp 1 is composed of a display part and an installation part. The display part includes a circuit board 10 on which a number of LED light sources 11 are mounted, and a mask 12 is placed at the light outlet. The mounting part of the luminaire 1 is a fixed bracket 13 made of a slotted aluminum alloy profile. On both sides of the fixed bracket 13, connecting pieces 14 are installed. The connecting pieces 14 are two arc-shaped aluminum alloy profiles. There is a round shaft 140, which penetrates into the arc-shaped sliding groove 130 provided on both sides of the fixed bracket 13, and the round shaft 140 can slide and rotate in the sliding groove 130. A through hole 141 is opened on the surface of the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com