Vehicle suspension ball head pin assembly

A ball stud and assembly technology, which is applied to vehicle components, steering mechanisms, steering rods, etc., can solve problems such as the inability to ensure the complete positioning of the lower ball bowl, the small swing angle of the ball stud pin, and the difficulty in ensuring the lower ball bowl. Achieve the effects of simple structure, increased swing angle and large swing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

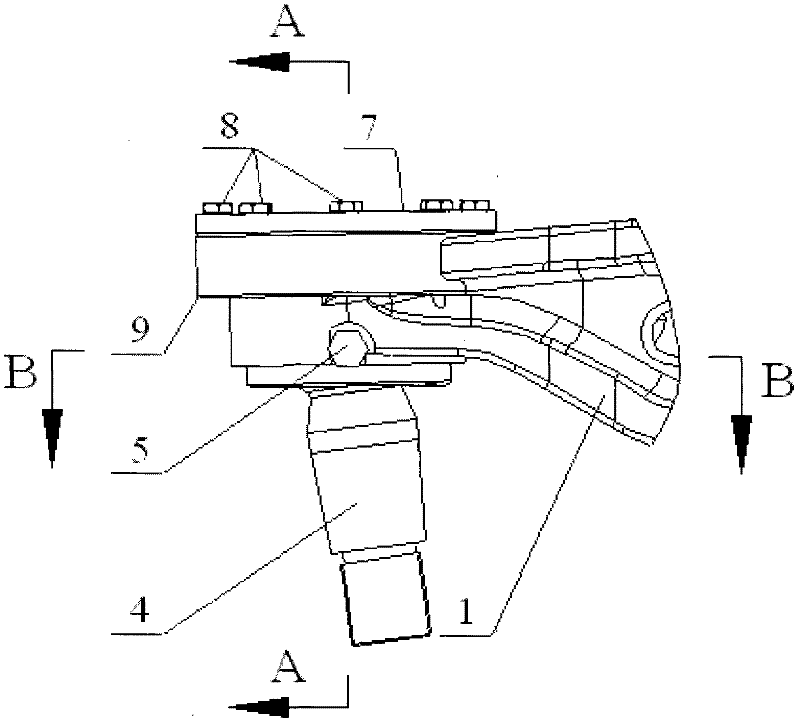

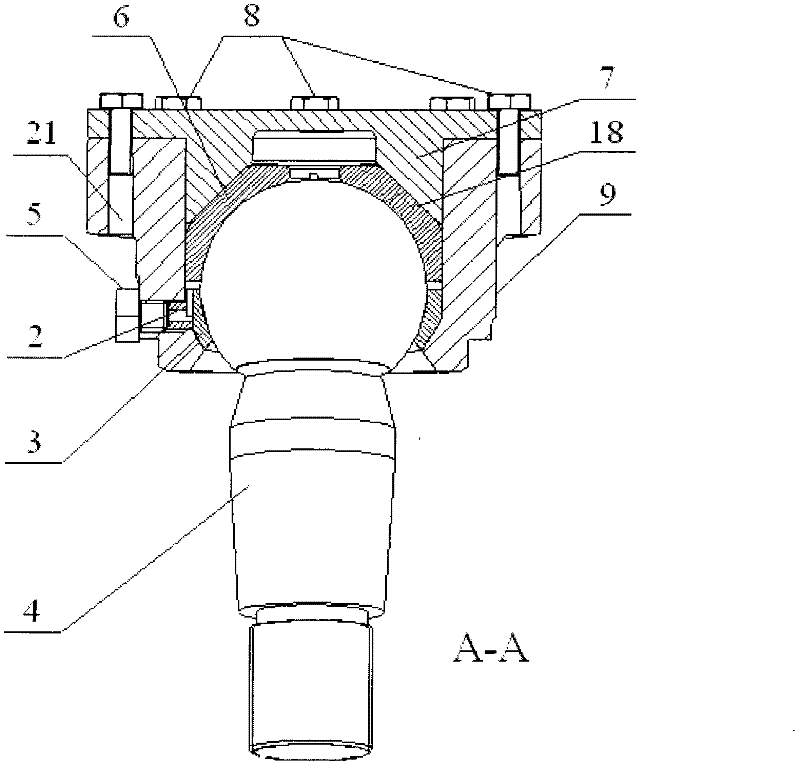

[0033] The vehicle suspension ball stud assembly of the present invention will be further described in detail below in conjunction with the accompanying drawings.

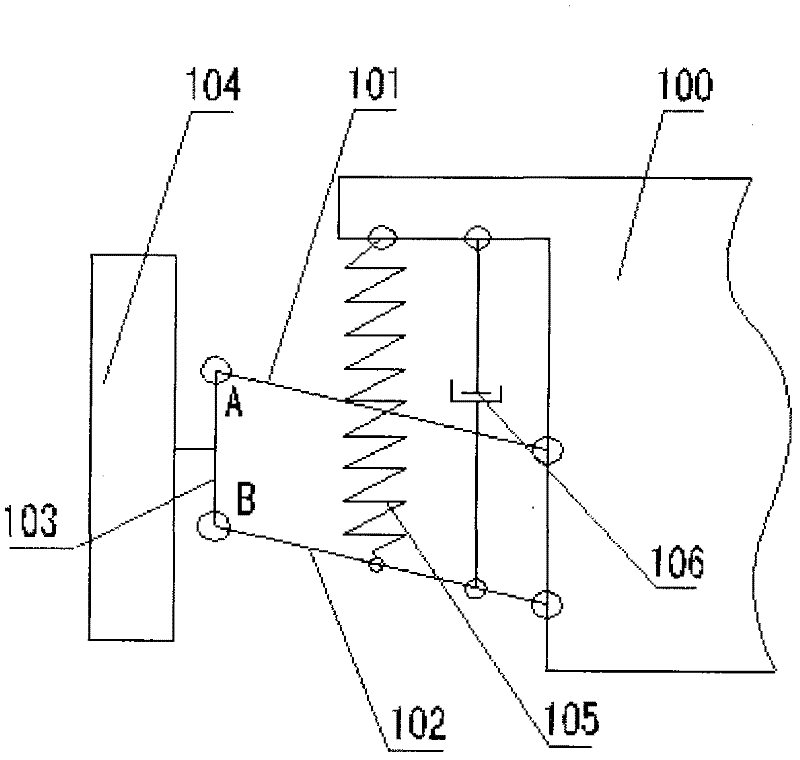

[0034] figure 1 A schematic diagram of the structural principle of the double-wishbone suspension mechanism is shown. like figure 1 As shown, the suspension mechanism is mainly composed of upper cross arm 101, lower cross arm 102, wheel 104, spring 105 and shock absorber 106, and the suspension mechanism forms a four-bar mechanism together with the wheel hub assembly 103 and the car body 100, which is the wheel 104 provides guidance and supports the vehicle body 100 . figure 1 Among them, A and B are the installation positions of the ball stud assembly of the present invention. The present invention connects the joints of the upper and lower cross arms 101, 102 and the hub assembly 103 through the ball stud assembly, and the ball stud is installed at the ends of the upper and lower cross arms 101, 102 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com