Automatic control device for radiating and ventilating facility of engine of contact net operation vehicle

An automatic control device and work vehicle technology, which is applied to engine components, machines/engines, and engine cooling, etc., can solve problems such as engine damage, automatic control of engine cooling and ventilation facilities not meeting intelligent standards, and affecting locomotive engine cooling effects. , to achieve the effect of reasonable structure, improved technology content and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

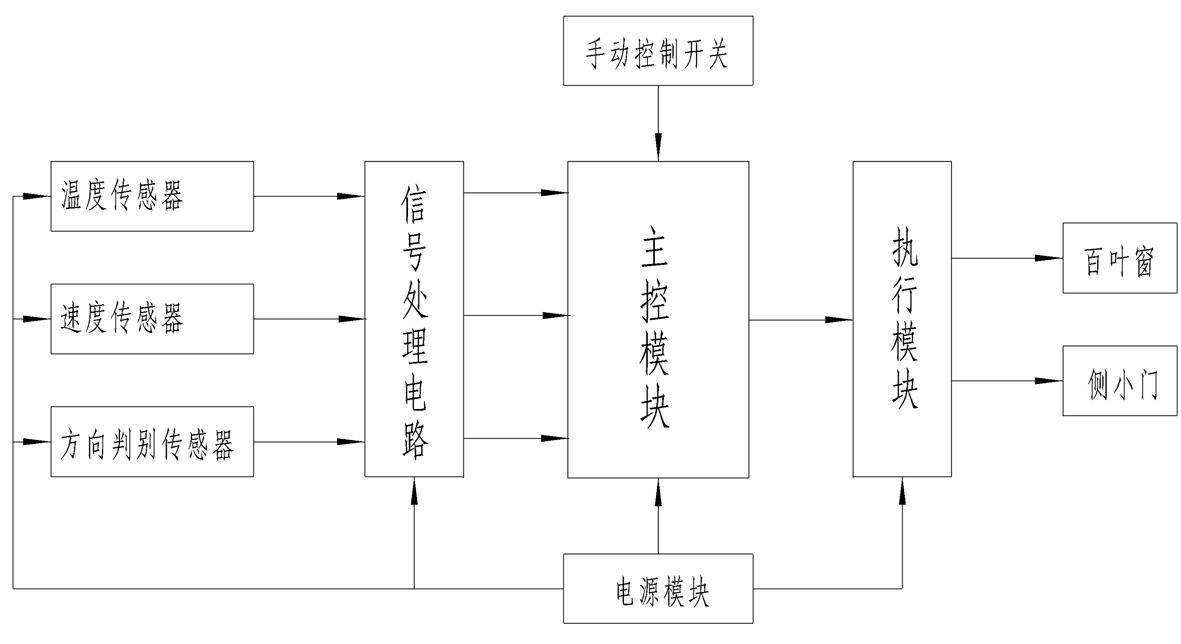

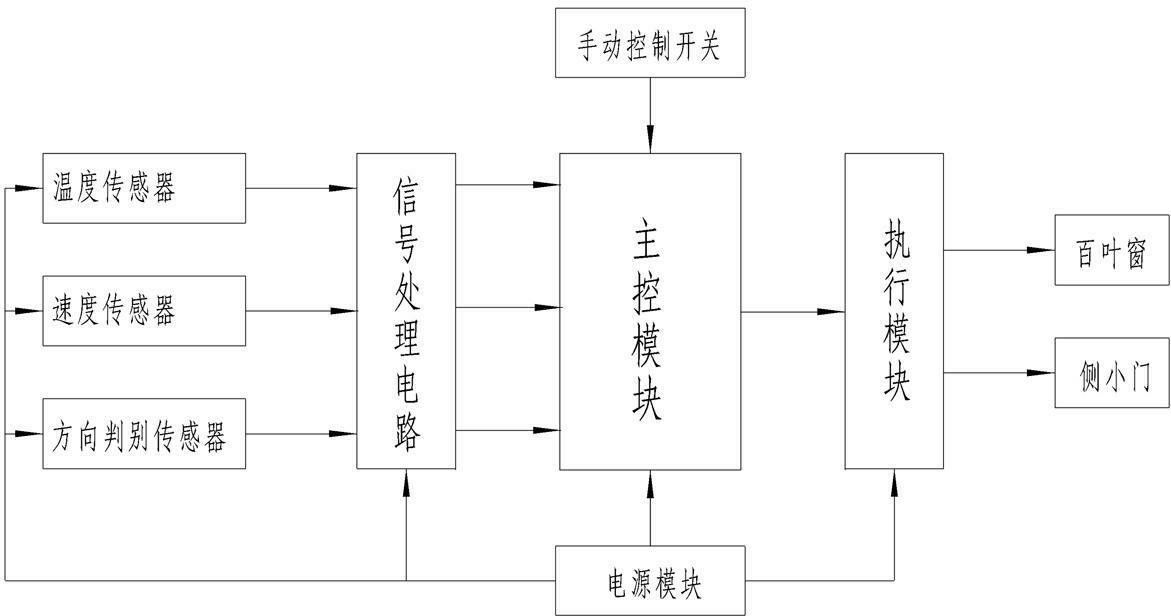

[0014] like figure 1 As shown, the automatic control device for the heat dissipation and ventilation facilities of the catenary operation vehicle engine. The heat dissipation and ventilation facilities of the catenary operation vehicle engine include shutters and small side doors. The signal acquisition module of the main control module, the execution module for manipulating the shutter and the opening and closing of the side door, and the power module for supplying power to each module, the output end of the signal acquisition module is connected with the signal acquisition input end of the main control module, and the control signal input end of the execution module is connected The control signal output terminal of the main control module is connected; the signal acquisition module includes a signal processing circuit, a temperature sensor for monitoring the temperature of the engine coolant, a speed sensor for monitoring the operating speed of the catenary operation vehicle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com