Method for assembling fixed ends of scaffold of large-volume triangular variable-section tubular truss structure

A technology of triangular and tube trusses, applied in building construction, processing of building materials, construction, etc., can solve problems such as small regularity, difficulty in arranging assembled tire frames, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

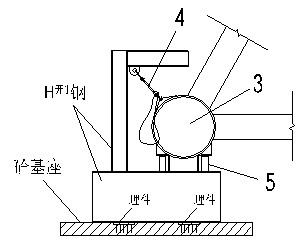

[0008] In the figure, the concrete foundation is poured on the ground, and the triangular sections at both ends of the large-scale pipe truss are built horizontally above it. After the assembly is completed, use a hoist to lift the puller and position it above the support system of the tire frame at a certain angle, and then assemble the rods between the two sections. After the assembly is completed, the end sections of the fixed end sections on both sides are removed and installed to the start section of the next assembled component. It is characterized in that: the ground concrete foundation is a triangular concrete bar, the maximum side length of which is larger than the maximum side length of the variable cross-section triangle to be assembled. It is characterized in that: the support system of the tire frame is a support system assembled by I-beams, which includes a chain hoist suspension point and a jack support point.

[0009] figure 1 , 2 In 3 and 4, a triangular ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com