Band type damper and preparation method thereof

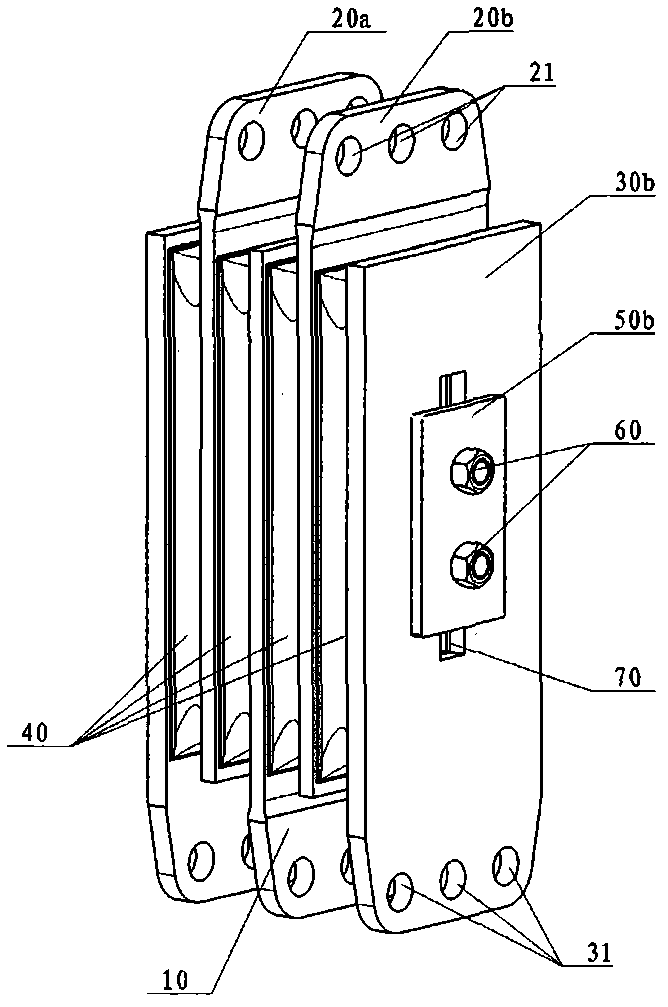

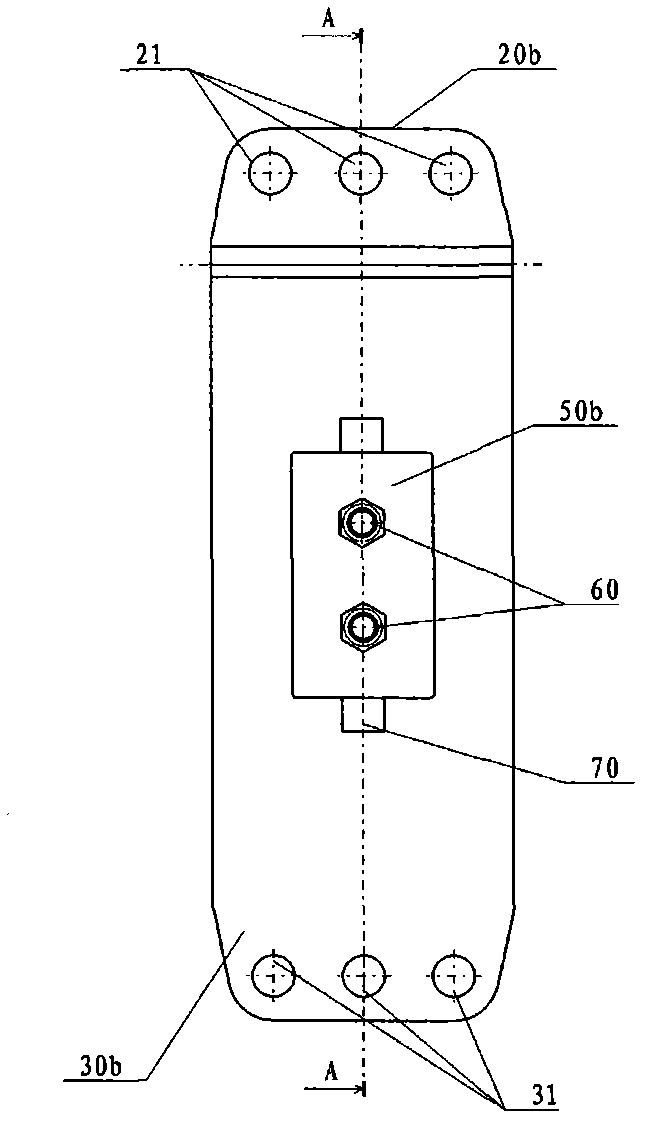

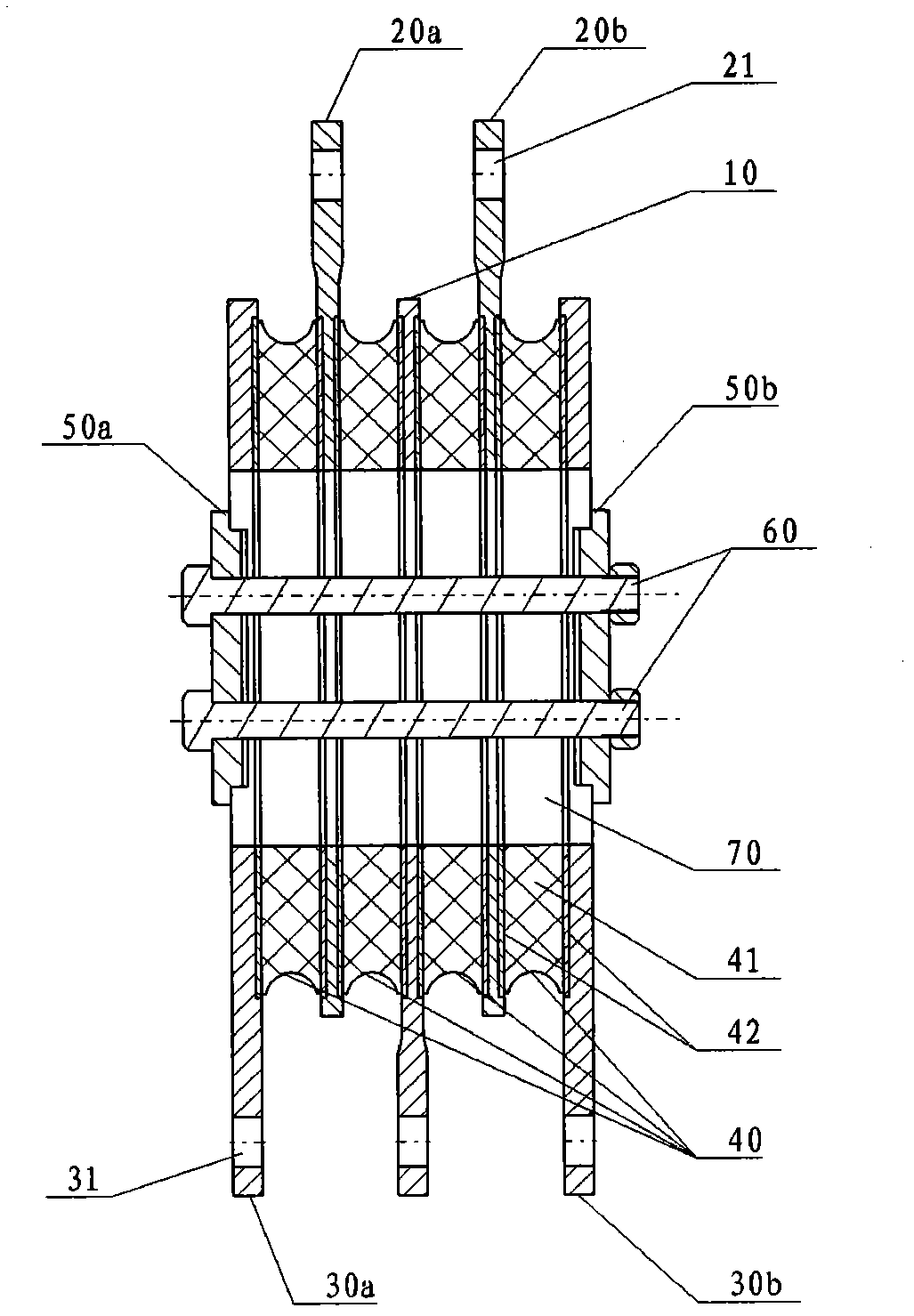

A damper and plate-type technology, which is applied in the improvement field of helicopter rotor plate-type dampers, can solve the problems of complex vulcanization molding molds, difficult processing, and high processing costs, and achieve the effects of low cost, easy processing, and small installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The left outer plate 30a, the left secondary middle plate 20a, the middle plate 10, the right secondary middle plate 20b and the right outer plate 30b are titanium alloy flat plates, which are processed on the outer surface of the left outer plate 30a corresponding to the four corners of the left pressing plate 50a There are four threaded holes, and four threaded holes are processed on the outer surface of the right outer plate 30b corresponding to the four corners of the right pressing plate 50b.

[0050] The material of the rubber plate 41 in the interlayer plate 40 is high damping silicon rubber, and the thickness of the metal plate 42 is 1.5mm, and the material is stainless steel.

[0051] The inner surface of the body of the left outer plate 30a, the two sides of the body of the left secondary middle plate 20a, the two sides of the body of the middle plate 10, the two sides of the body of the right secondary middle plate 20b and the inner surface of the body of the ...

Embodiment 2

[0057] The left outer plate 30a, the left secondary middle plate 20a, the middle plate 10, the right secondary middle plate 20b and the right outer plate 30b are flat plates made of stainless steel, and finite grooves are respectively processed in the middle of the outer surfaces of the left outer plate 30a and the right outer plate 30b.

[0058] The rubber plate 41 in the sandwich plate 40 is made of damping foam material, and the metal plate 42 has a thickness of 3 mm and is made of aluminum alloy.

[0059] The inner surface of the body of the left outer plate 30a, the two sides of the body of the left secondary middle plate 20a, the two sides of the body of the middle plate 10, the two sides of the body of the right secondary middle plate 20b and the inner surface of the body of the right outer plate 30b Grooves having the same dimensions as the metal plate 42 are correspondingly processed respectively.

[0060] The material of the left pressing plate 50a and the right pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com