Track changing control system for inspection vehicle and control method

A control system and inspection vehicle technology, which is applied to railway car body parts, and uses the passage of vehicles to control turnouts, buildings, etc., can solve the problems of wasting time and resources, increase labor intensity, etc. Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

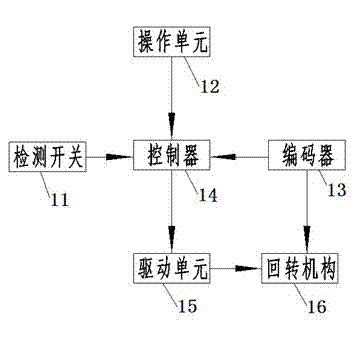

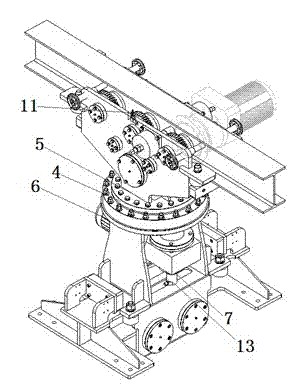

[0020] like Figure 1 to Figure 3 As shown, the track control system of the inspection vehicle includes a detection switch 11, an operation unit 12, an encoder 13, a controller 14, a drive unit 15, and a turning mechanism 16, among which: the detection switch 11, the operation unit 12, the encoder 13, and the drive unit 15 are respectively connected to the controller 14 through signal wires, the encoder 13 is mechanically connected to a set of gears of the rotary mechanism 16, and the drive unit 15 is electrically connected to the rotary motor 6 of the rotary mechanism 16; the detection switch 11 is used for detection and inspection Whether the car arrives at the center position of the revolving track and outputs the detection signal to the controller 14; the operation unit 12 is used to output the direction control signal to the controller 14; output to the controller 14; the controller 14 is used to receive the angle information output by the encoder 13 and the direction con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com