Pin assembling and disassembling device

A loading and unloading device and pin shaft technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of affecting the appearance quality, low efficiency, time-consuming and laborious manual disassembly and assembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

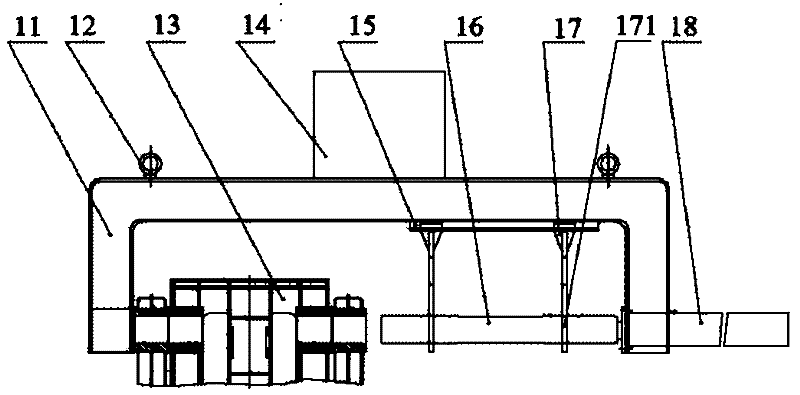

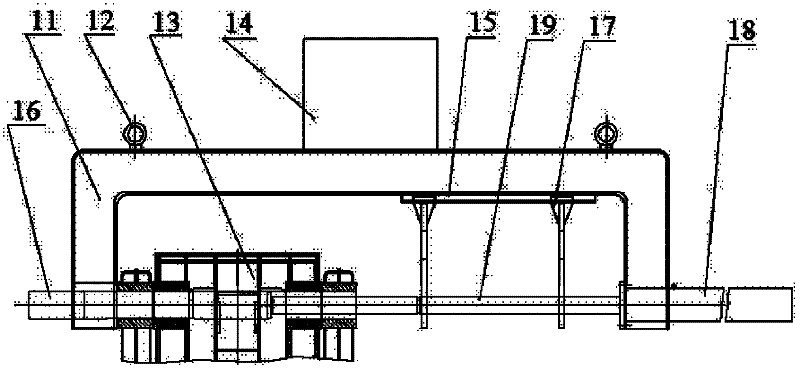

[0020] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

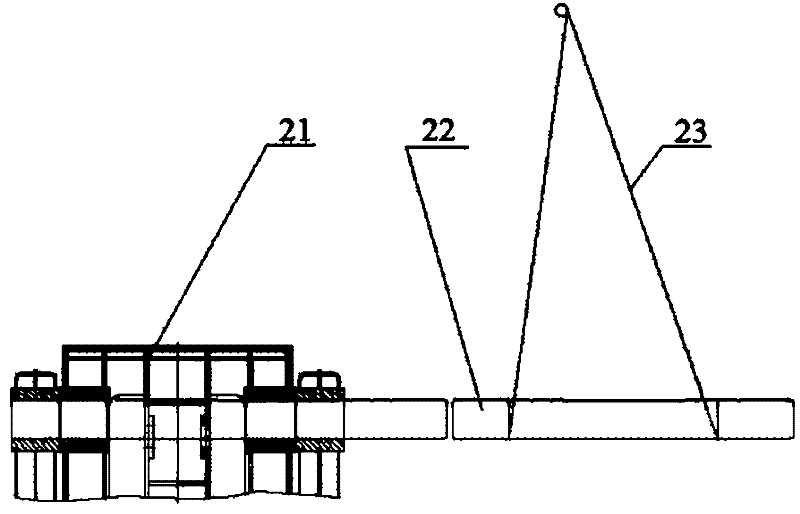

[0021] figure 2 A schematic diagram of a pin handling device according to an embodiment of the present invention is shown in . The pin shaft loading and unloading device of the present invention comprises: a door frame 11 straddling the top of the to-be-installed piece 13 and the pin shaft 16; a bracket 17, connected below the door frame 11, having a hoisting part 171 for hanging the pin shaft 16, and the hoisting part 171 hangs the pin shaft 16 to be installed; the hydraulic cylinder 18 is fixedly connected with the door frame, and the piston 19 is telescopically driven to connect with the pin shaft 16 .

[0022] This embodiment also includes: a slide rail 15, which is fixedly connected under the door frame 11, and the bracket 17 can slide freely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com