Safety control device for welders in special operating environments

A technology for working environment and safety control, applied in auxiliary devices, combined devices, manufacturing tools, etc., can solve the problems of difficult air circulation and difficult mechanical exhaust fan discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Take the application of the present invention in welding construction in natural gas pipeline cross-river tunnels as an example.

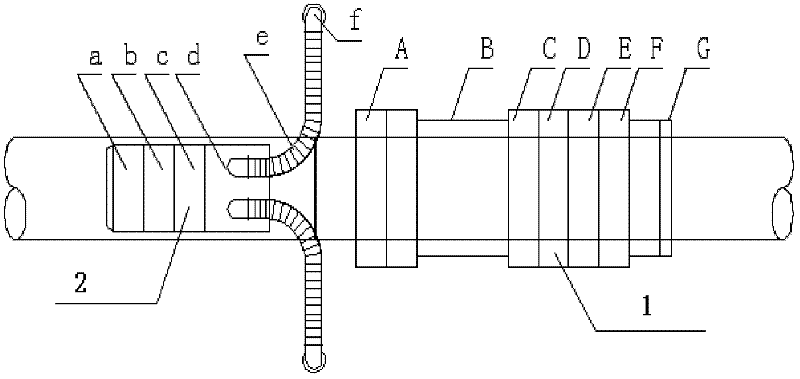

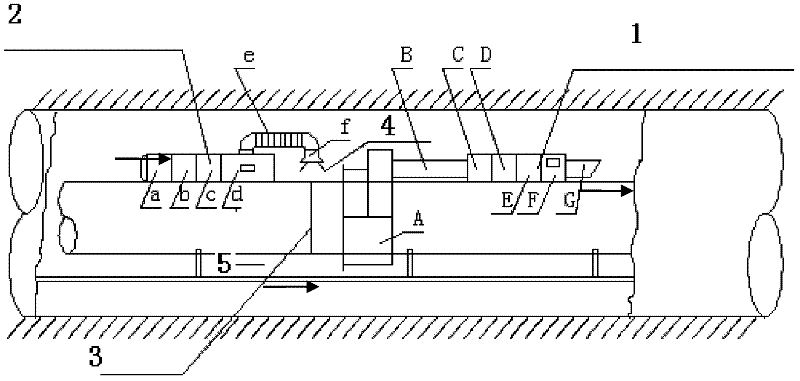

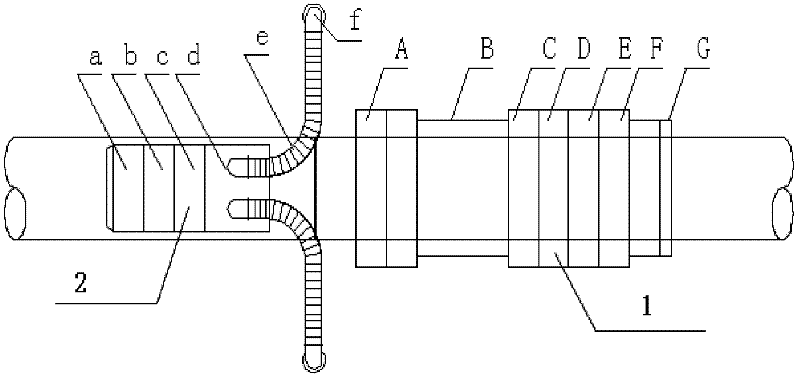

[0019] Such as figure 1 and figure 2 As shown, the present invention is a safety control device for welders in a special working environment, including a smoke and dust discharge treatment device and a purification air supply device. In the opposite direction of the exhaust port of the device, the two sets of devices are activated at the same time during use; the on-site soot discharge treatment device includes a side suction hood A for smoke and dust, and a first-stage filter is arranged inside the side suction hood A for smoke and dust. The dust side suction hood A is connected to the first and second stage filter C through the communication pipe B, and the first and second stage filter C is connected with the first electronic purifier D, namely the first and third stage filter, so The above-mentioned first electronic purifier D is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com