Small-sized fuel adjuster of turbojet engine

A technology of turbojet engine and fuel regulator, which is applied to engine components, turbine/propulsion fuel delivery system, fuel control of turbine/propulsion device, etc. It can solve problems such as low adjustment ratio, high requirements for actuators, and complex structure. Achieve the effect of large adjustment ratio, fast response speed and high adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

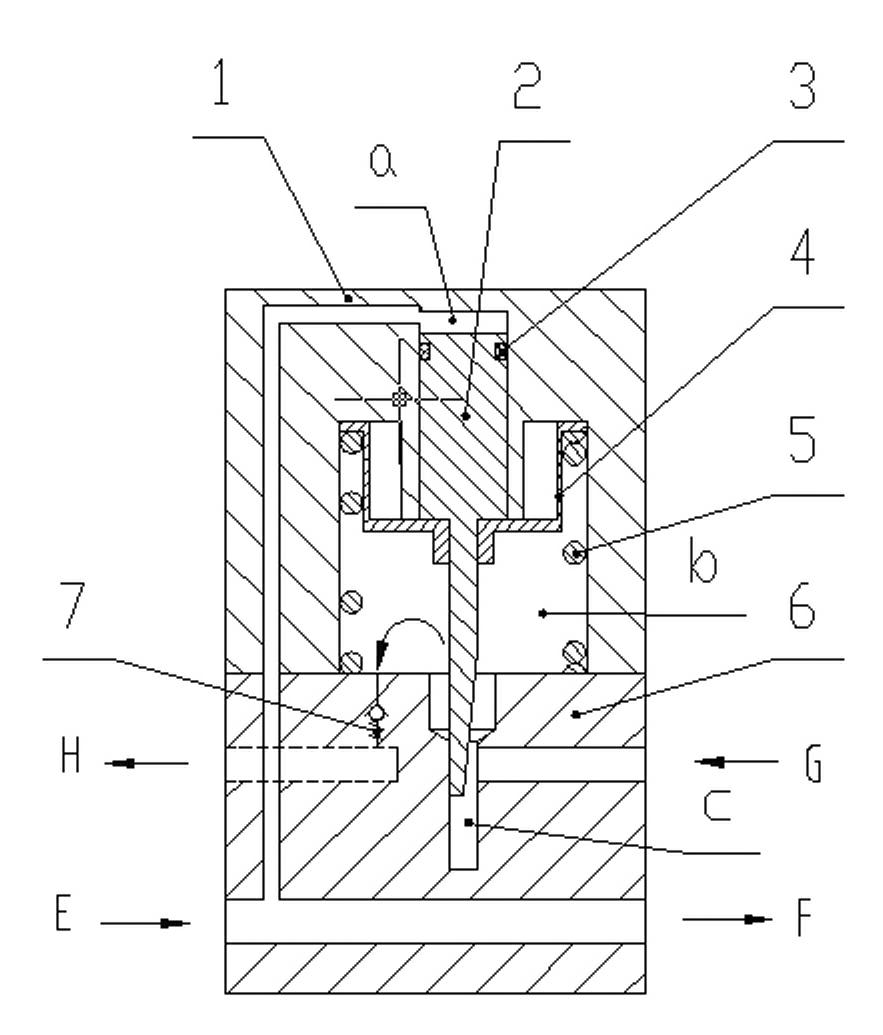

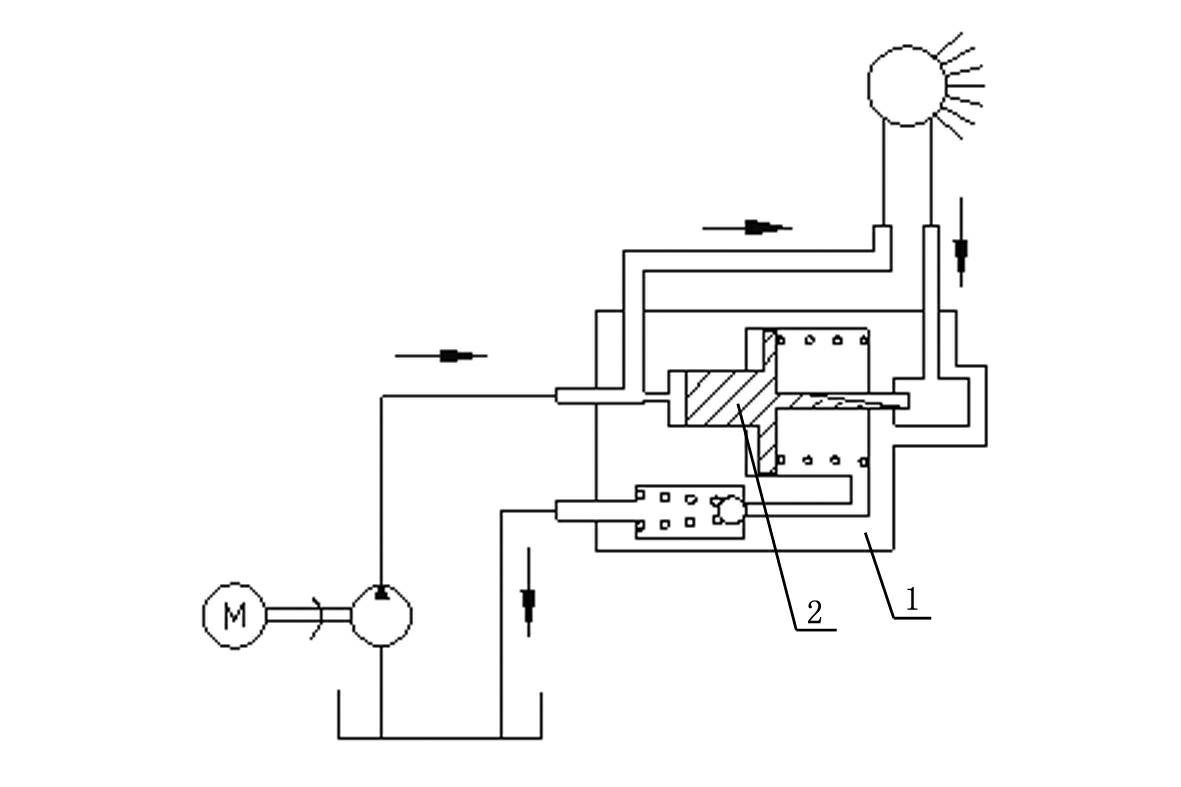

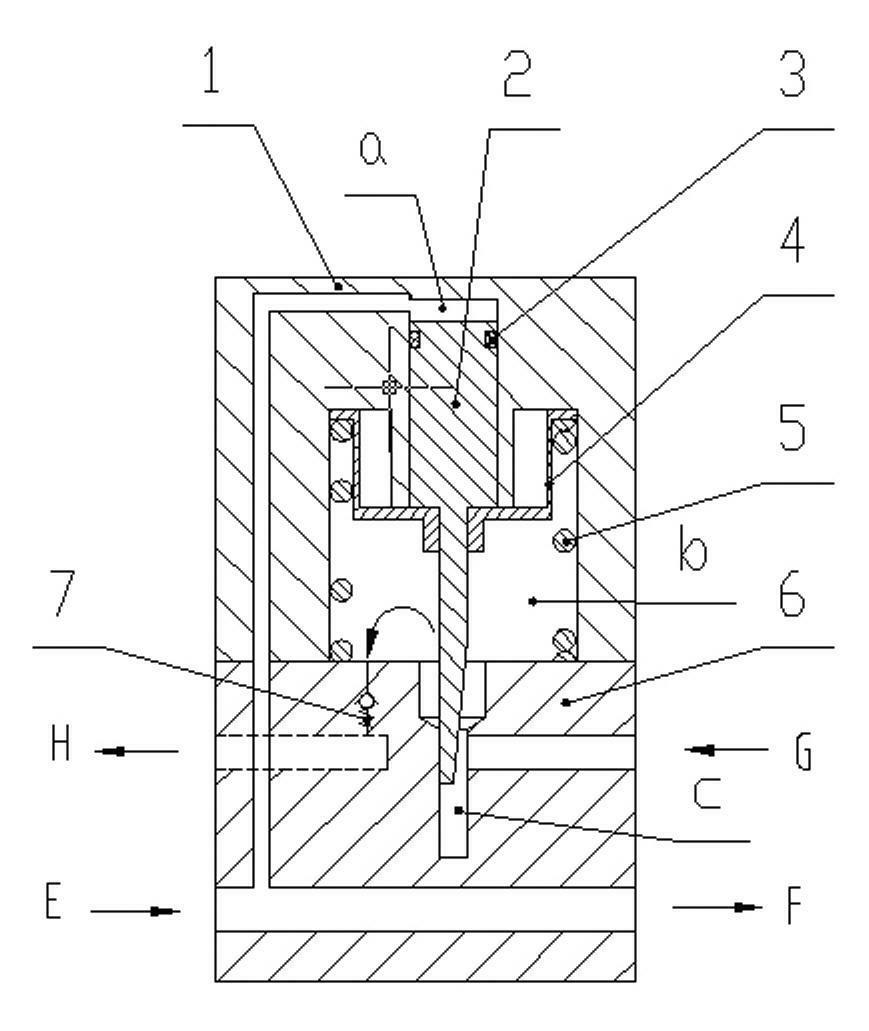

[0011] Refer to attached figure 1 , 2 , small turbojet engine fuel regulator consists of housing 1, regulating needle 2, O-ring 3, spring cover 4, spring 5, oil distribution block 6, check valve 7, spring cover 4, spring 5 and regulating needle 2 installed into one. An oil distribution block 6 is installed in the housing 1, and the oil distribution block 6 is provided with cavities a, b and c, the spring 5 is installed in the b cavity of the oil distribution block, the spring cover 4 is installed on the spring 5, and the spring The cover 4 is provided with an adjustment needle installation hole, the upper part of the adjustment needle 2 is installed in the chamber a, the lower part of the adjustment needle 2 is designed with a special-shaped adjustment end, and the special-shaped adjustment end is inserted into the adjustment hole between the chamber b and c chamber, and the upper part of the adjustment needle 2 is installed There is an O-ring 3 through which the oil inlet a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com