Method for producing sophorolipid through fermentation of lignocellulose material

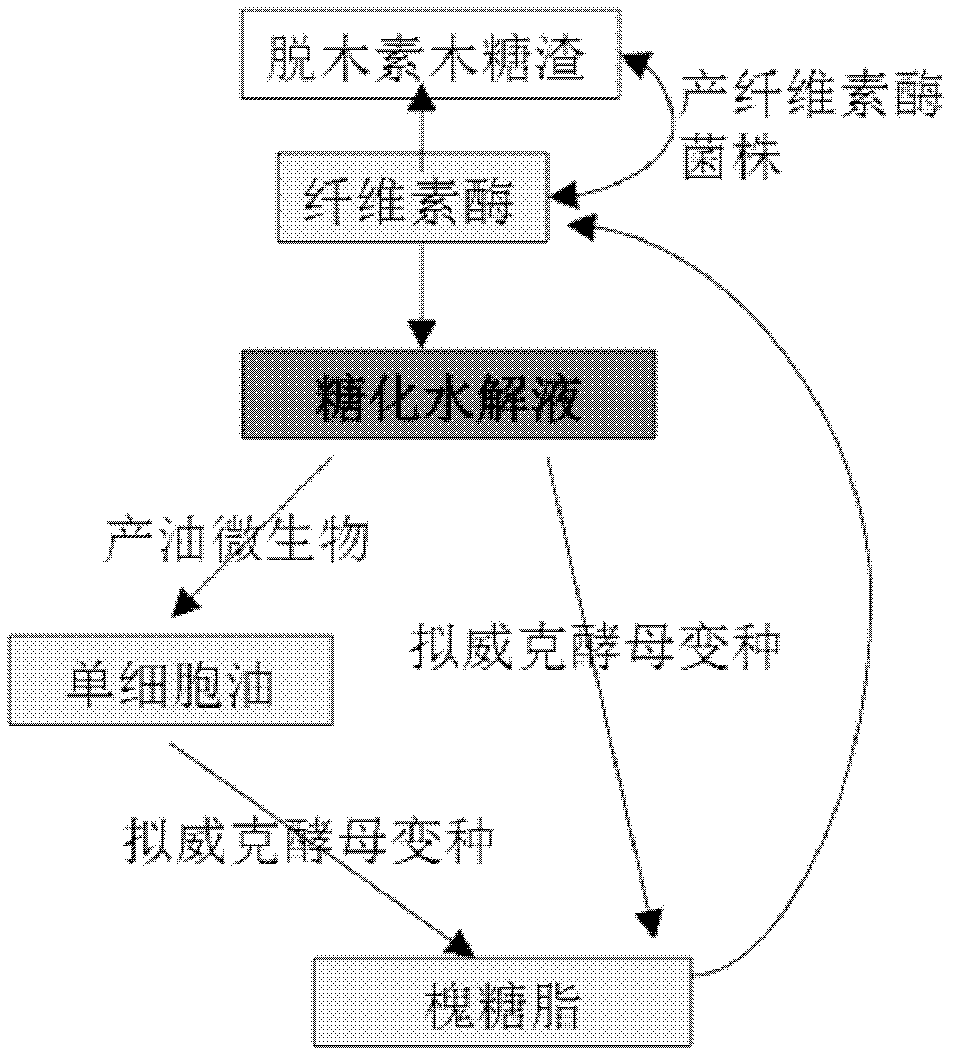

A technology for lignocellulose and microbial fermentation biosurfactant, which is applied in the field of using lignocellulosic material to ferment and produce microbial fermentation biosurfactant by using a Wick yeast variant, and achieves the effects of improving energy shortage, simple process and easy separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation of cellulase solution: Penicillium decumbens JU-A10 was inoculated into the enzyme-producing medium in a conventional amount, cultured at 30°C, shaking at 250 rpm for 96 hours to produce enzyme, centrifuged at 6000 rpm for 30 minutes, and collected The supernatant is the crude cellulase enzyme solution;

[0028] The above-mentioned enzyme production medium formula is: 20g / l xylose residue, 30g / l bran, 6g / l microcrystalline cellulose, 5g / l soybean meal, 2g / l ammonium sulfate, 1g / l urea, 2g / l nitric acid Sodium, 3g / l potassium dihydrogen phosphate, 0.5g / l magnesium sulfate, 3ml / l Tween 80;

[0029] (2) Preparation of saccharification solution: take the delignified xylose residue, add cellulase solution to 25 FPA per gram of dry substrate, and saccharify at 45°C for 72 hours; collect the saccharification solution in a water bath at 80°C for 30 minutes to make residual cellulose The enzyme is inactivated, and the saccharification solution is centrifuged at 8000 ...

Embodiment 2

[0036] (1) Preparation of cellulase solution: Inoculate Penicillium decumbens in the enzyme-producing medium in a conventional amount, culture at 30°C, shaking at 250 rpm for 84 hours to produce enzyme, centrifuge at 6000 rpm for 30 minutes, and collect the supernatant to obtain cellulose. Enzyme crude enzyme solution;

[0037] The above-mentioned enzyme production medium formula is: 20g / l xylose residue, 30g / l bran, 6g / l microcrystalline cellulose, 5g / l soybean meal, 2g / l ammonium sulfate, 1g / l urea, 2g / l nitric acid Sodium, 3g / l potassium dihydrogen phosphate, 0.5g / l magnesium sulfate, 3ml / l Tween 80;

[0038] (2) Preparation of saccharification solution: take the delignified xylose residue, add cellulase solution to 30 FPA per gram of dry substrate, and saccharify at 45°C for 72 hours; collect the saccharification solution in a water bath at 80°C for 30 minutes to make residual cellulose The enzyme is inactivated, and then the saccharification solution is centrifuged at 9000 rp...

Embodiment 3

[0045] (1) Preparation of saccharification solution: take the delignified xylose residue, add 25 FPA per gram of dry substrate to a commercial cellulase solution (from Qingdao Kang Dien Biotechnology Co., Ltd.), the buffer system is pH 4.8 Saccharification with 0.05M HAC-NaAc buffer solution at 45℃ for 72h; Collect the saccharification solution in a water bath at 80℃ for 30min to inactivate the residual cellulase, and then centrifuge the saccharification solution at 8000rpm for 10min to obtain a clear saccharification solution;

[0046] (2) Detoxification treatment of the saccharification solution: heat the saccharification solution to 80°C in a water bath, add 1.0% by mass activated carbon, stir for 30 minutes, and then remove the activated carbon by vacuum filtration to obtain a detoxified saccharification solution;

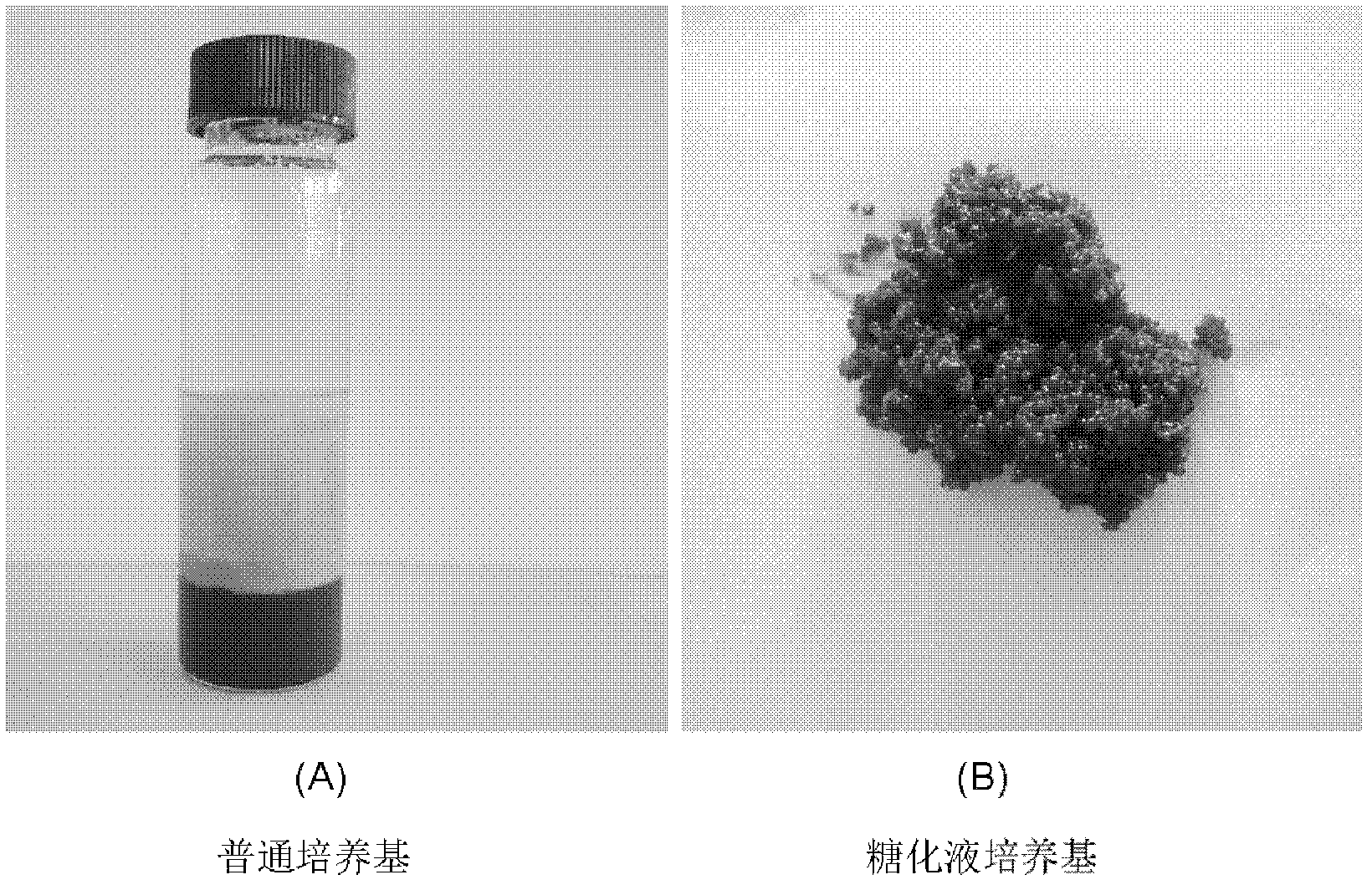

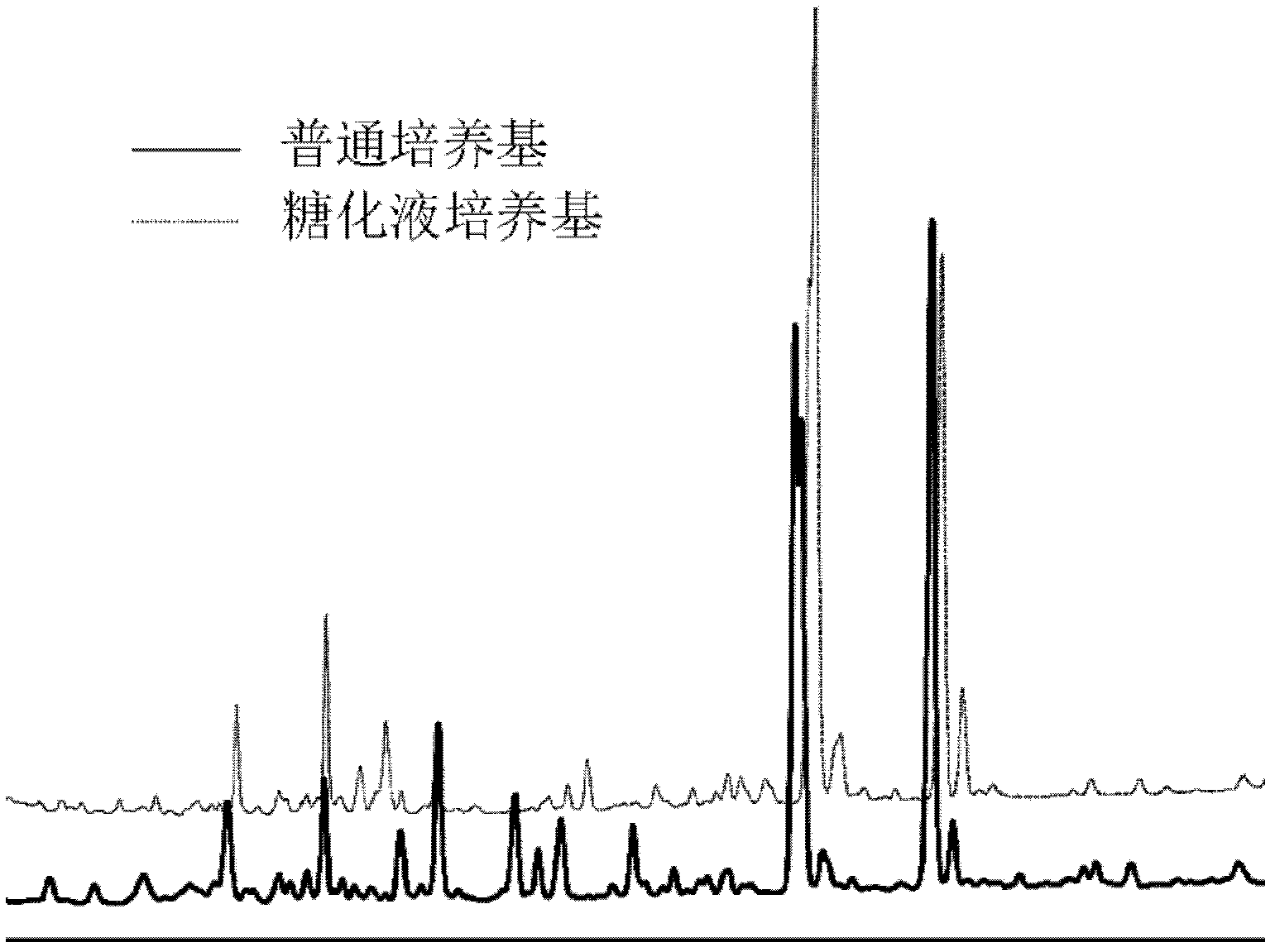

[0047] (3) Use saccharification solution to prepare single-cell oil: prepare an oil-producing saccharification solution fermentation medium with a formula of detoxif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com