High-concentration nano-carbon cotton special fertilizer and preparation method thereof

A cotton-specific fertilizer and nano-carbon technology, which can be used in applications, fertilization devices, fertilizer mixtures, etc., can solve the problems of uneven fertilizer nutrients, low fertilizer utilization rate, poor dissolution, etc., and achieve balanced fertilizer, high fertilizer utilization, and improved Effects on cotton yield and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Melt 540 parts of urea at a high temperature of about 135°C, enter the buffer tank, pressurize it through a delivery pump, and pump it into the top mixer;

[0065] 140 parts of potassium dihydrogen phosphate, 210 parts of potassium chloride, 100 parts of monoammonium phosphate, 50 parts of calcium magnesium phosphate fertilizer, 26.5 parts of ferrous sulfate, 10 parts of zinc sulfate, 10 parts of EDTA chelated manganese, 10 parts of borax, 0.5 parts Ammonium molybdate and 3 parts of nano-carbon, after metering, are sent to the mixer and mixed evenly; after the mixed raw materials are crushed and screened, they are sent to the mixing heater to be heated to about 90°C; they are sent to the top of the tower by a bucket elevator Silo.

[0066] The hot mixture in the silo at the top of the tower is evenly measured by the spiral meter, and then sent to the above mixer, mixed by a high-speed shear mixer to make a thin paste material, the temperature is controlled at about 110 ...

Embodiment 2

[0069] Take 500 parts of urea, 140 parts of potassium dihydrogen phosphate, 100 parts of monoammonium phosphate, 250 parts of potassium chloride, 50 parts of calcium magnesium phosphate fertilizer, 26.5 parts of ferrous sulfate, 10 parts of zinc sulfate, 10 parts of manganese chelated with EDTA, and 10 parts of borax 0.5 part, 0.5 part of ammonium molybdate, 3 parts of nano carbon;

[0070] Concrete production technology is with embodiment 1.

[0071] The obtained special fertilizer for high-concentration nano-carbon cotton has a ratio of nitrogen, phosphorus and potassium of 23-8-20, and contains nano-carbon and medium and trace elements.

Embodiment 3

[0073] Get 540 parts of urea, 300 parts of potassium chloride, 60 parts of potassium dihydrogen phosphate, and 100 parts of monoammonium phosphate; the specific production process is the same as in Example 1.

[0074] The obtained product has a ratio of nitrogen, phosphorus and potassium of 26-8-20, and does not contain nano-carbon and medium and trace elements.

[0075] Comparative example: 54% ordinary potassium chloride compound fertilizer, the ratio of nitrogen, phosphorus and potassium is 18-18-18, and it is Sanan compound fertilizer produced by Stanley Fertilizer Co., Ltd.

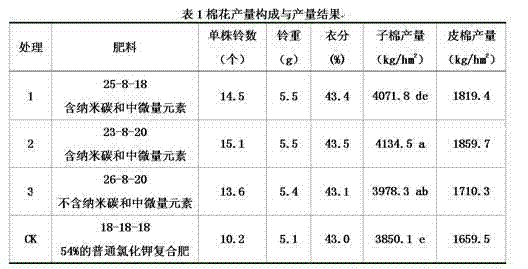

[0076] Xinjiang is the largest high-quality cotton production base in my country. The "National Cotton Engineering Technology Research Center" was established in Xinjiang with the approval of the Ministry of Science and Technology in 1998. The applicant signed a strategic cooperation agreement with the National Cotton Engineering Technology Research Center in 2008. Therefore, the company The experimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com