Ocean platform crane

An offshore platform and crane technology, applied in the direction of cranes, etc., can solve the problems of affecting the normal operation of the crane, destroying the boom or pile leg structure, and the boom being easy to touch the pile legs, etc., so as to save valuable space and protect the safety and convenience of the structure. The effect of structural arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

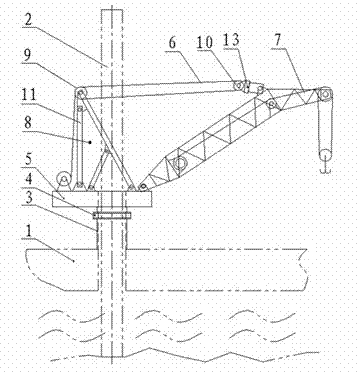

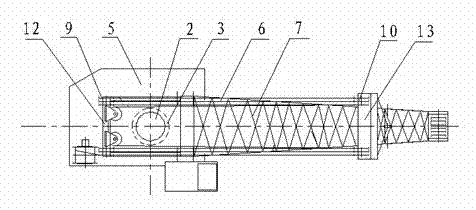

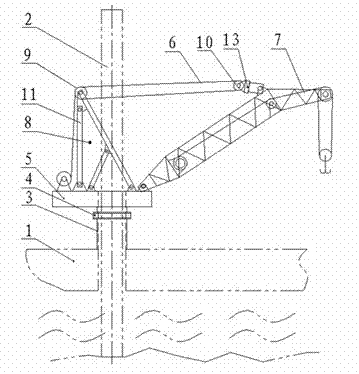

[0024] Specific embodiment: the offshore platform crane provided by the present invention has a design lifting capacity of 190 tons, the maximum outer diameter of the pile leg 1 is 3258mm, the inner diameter of the base column 3 is 3648mm, and a gap of 195mm is left on one side, and the inner diameter of the through hole of the turntable 5 is 3668mm. The minimum distance between the two sides of the luffing steel wire rope 6 at the pile leg 1 is 4539 mm, which is greater than the outer diameter of the pile leg 1 of 3258 mm. A sufficient safety distance is left between the pile leg 1 and the turntable 5, the base column 3 and the luffing wire rope 9, so that the pile leg 2 can move up and down freely when lifting and lowering without colliding with any part of the crane, and the operation of the pile leg and the crane The operation is safe and reliable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com