Wood working machine and processing platform thereof

A technology for processing platforms and woodworking machinery, applied in wood processing appliances, multi-purpose machinery, manufacturing tools, etc., to achieve the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0015] The woodworking machine of the present invention is suitable for processing prefabricated wooden squares used in building wooden houses. According to the requirements for wooden squares calculated by the software design wooden house, the wooden squares are cut in length, grooved and drilled, and each wooden The square materials are spray coded, and the workers perforate and groove the wooden square materials according to the codes and drawings, and assemble them into wooden houses.

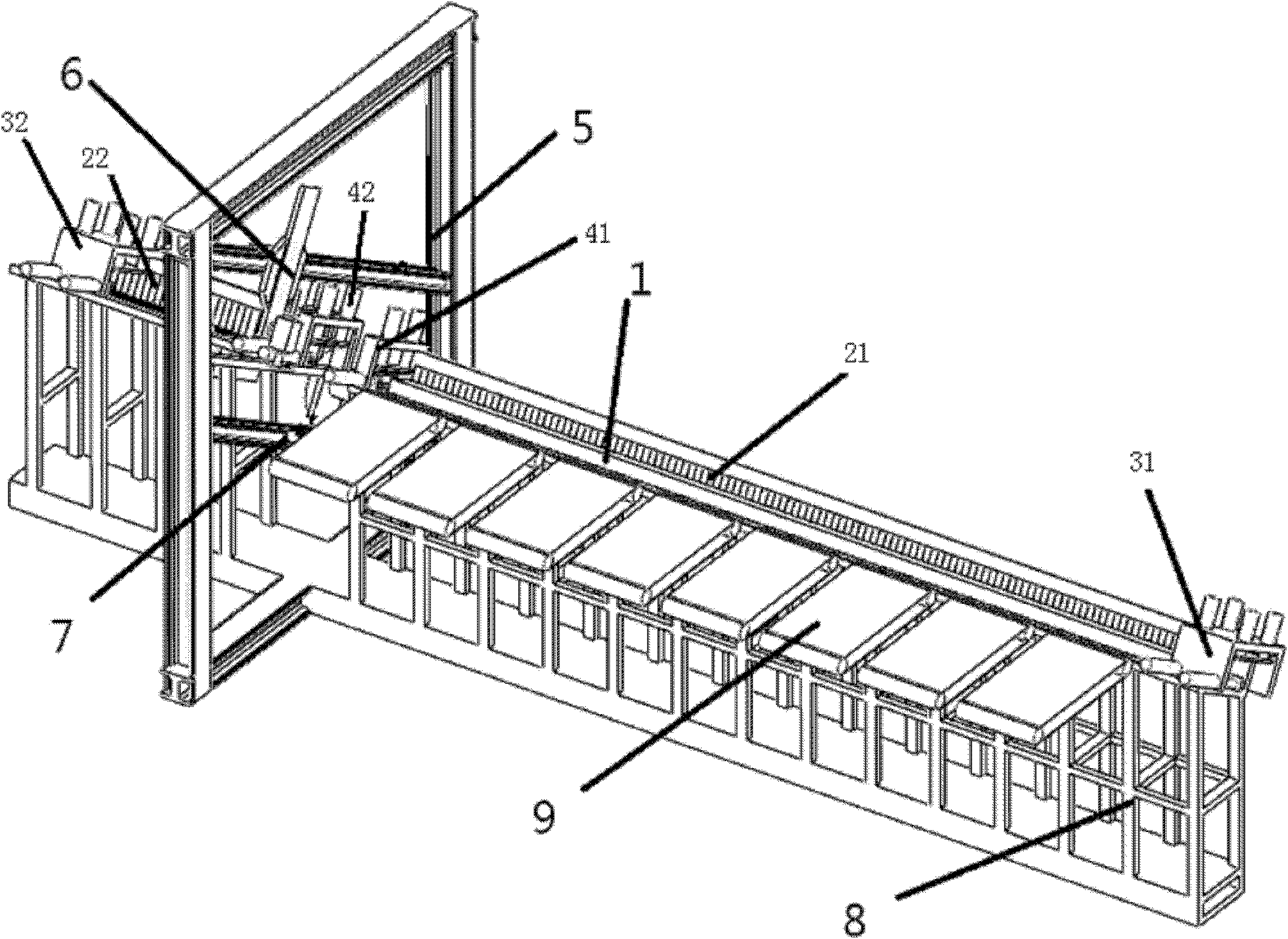

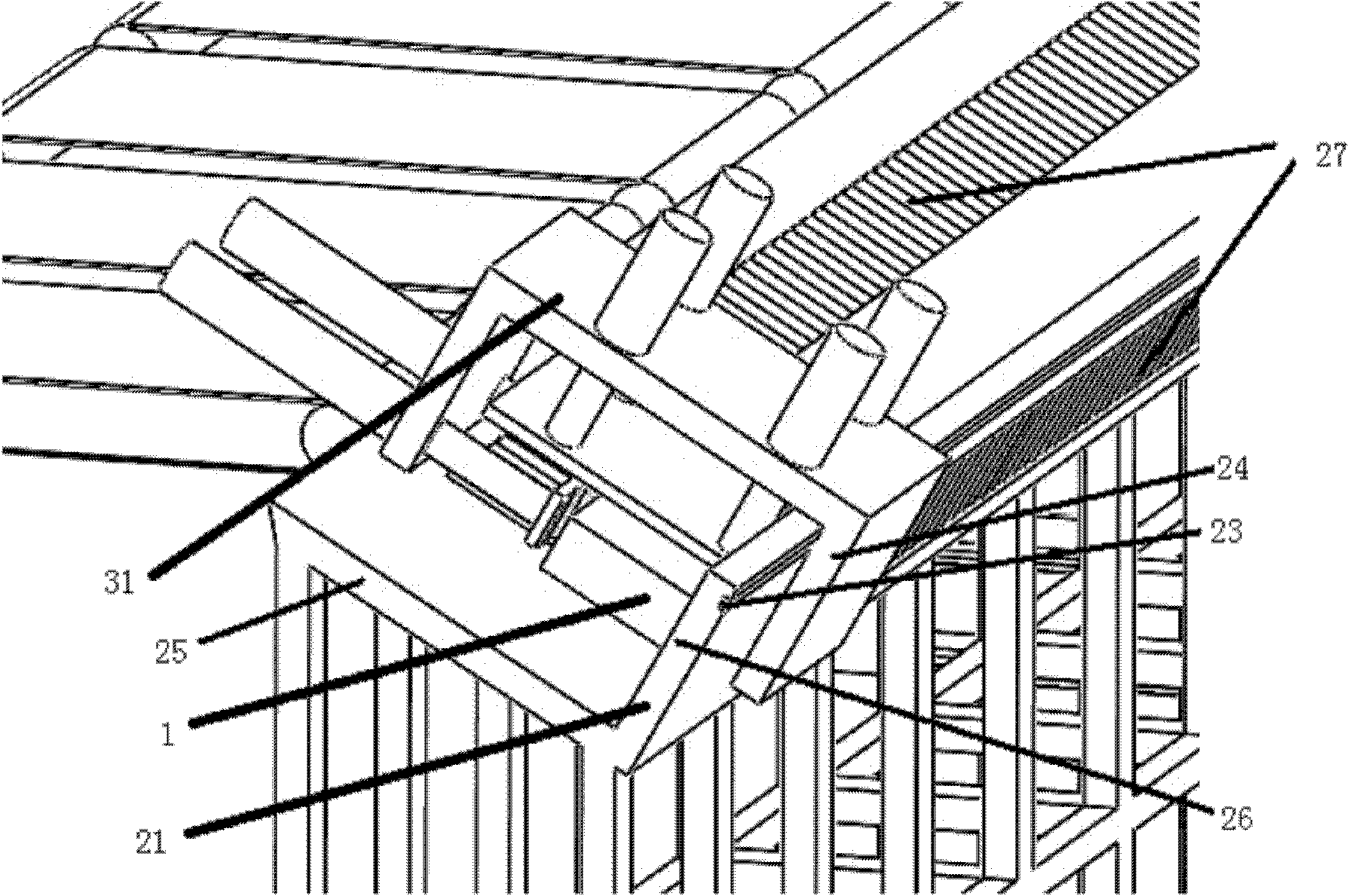

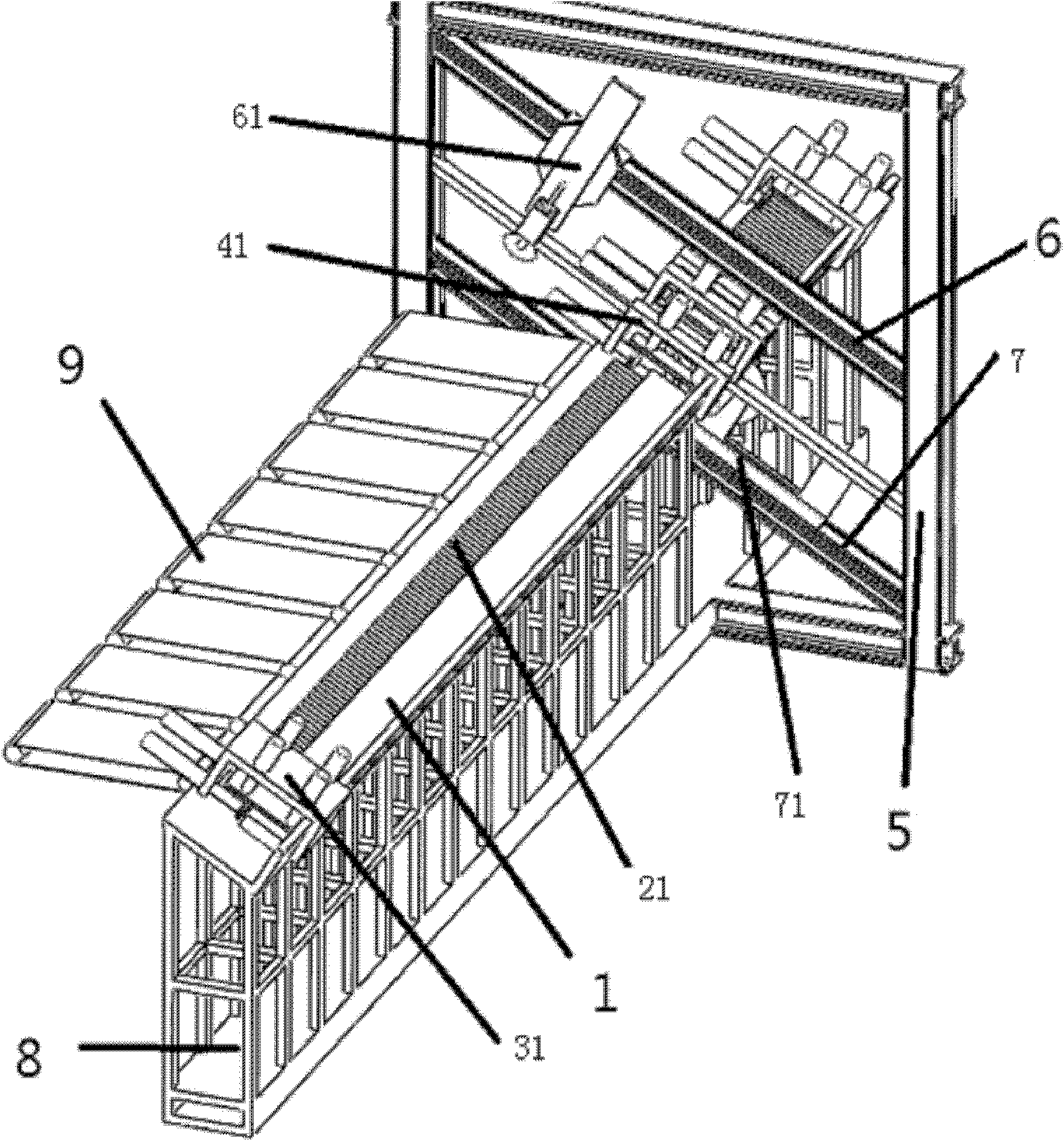

[0016] see figure 1 and figure 2 , The wood processing machine of the present invention can complete various processes such as drilling, grooving, cutting, and coding. The whole machine is supported by an integral support frame 8, including three parts, the feeding area, the processing area and the discharging area. The feeding area is designed to be longer due...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com