Highly processable steel sheet for three-piece welded can and method for producing same

A manufacturing method and processability technology, applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., can solve problems such as steel plate cracks, and achieve the effect of thinning the wall and excellent flanging processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

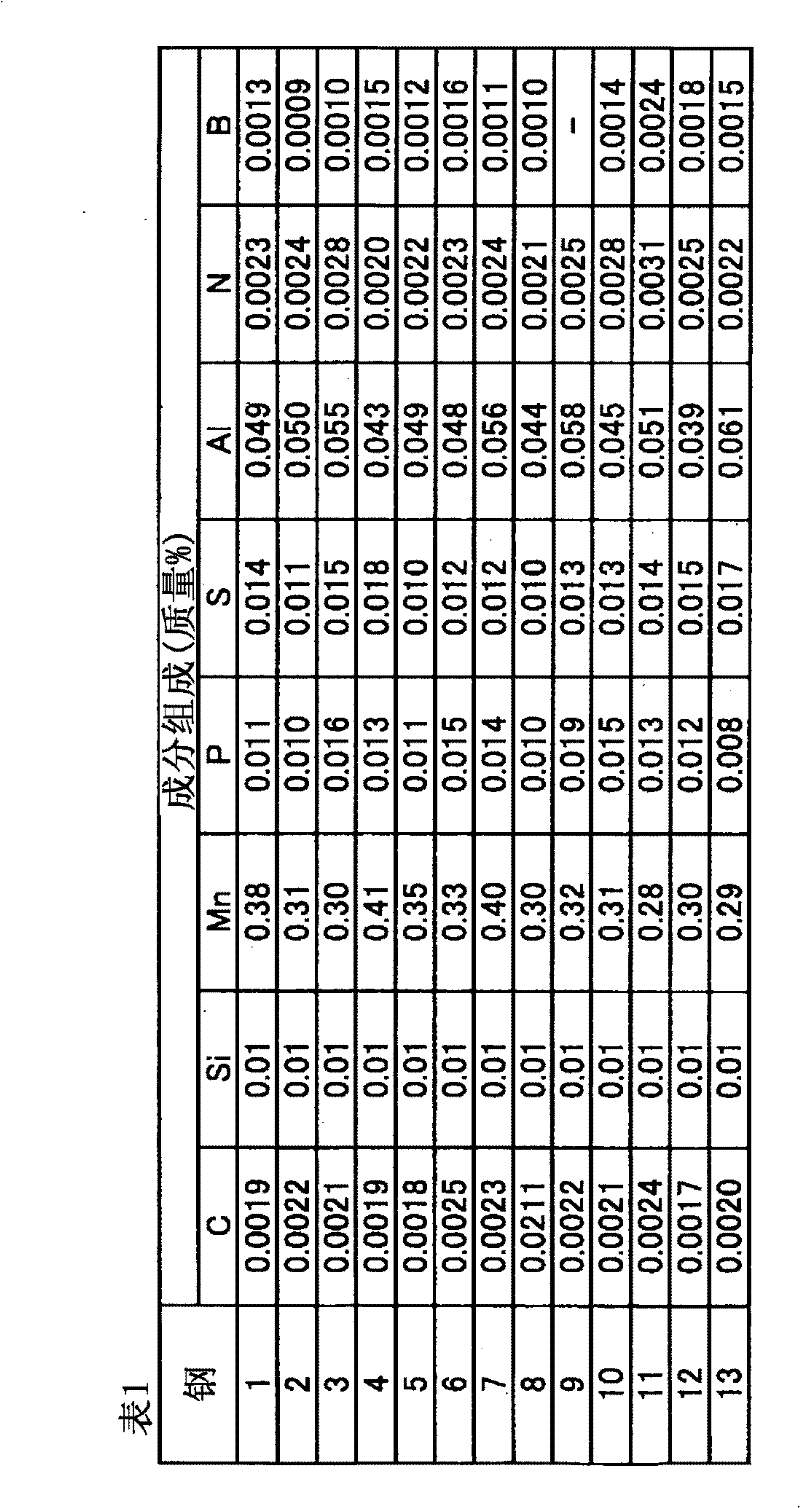

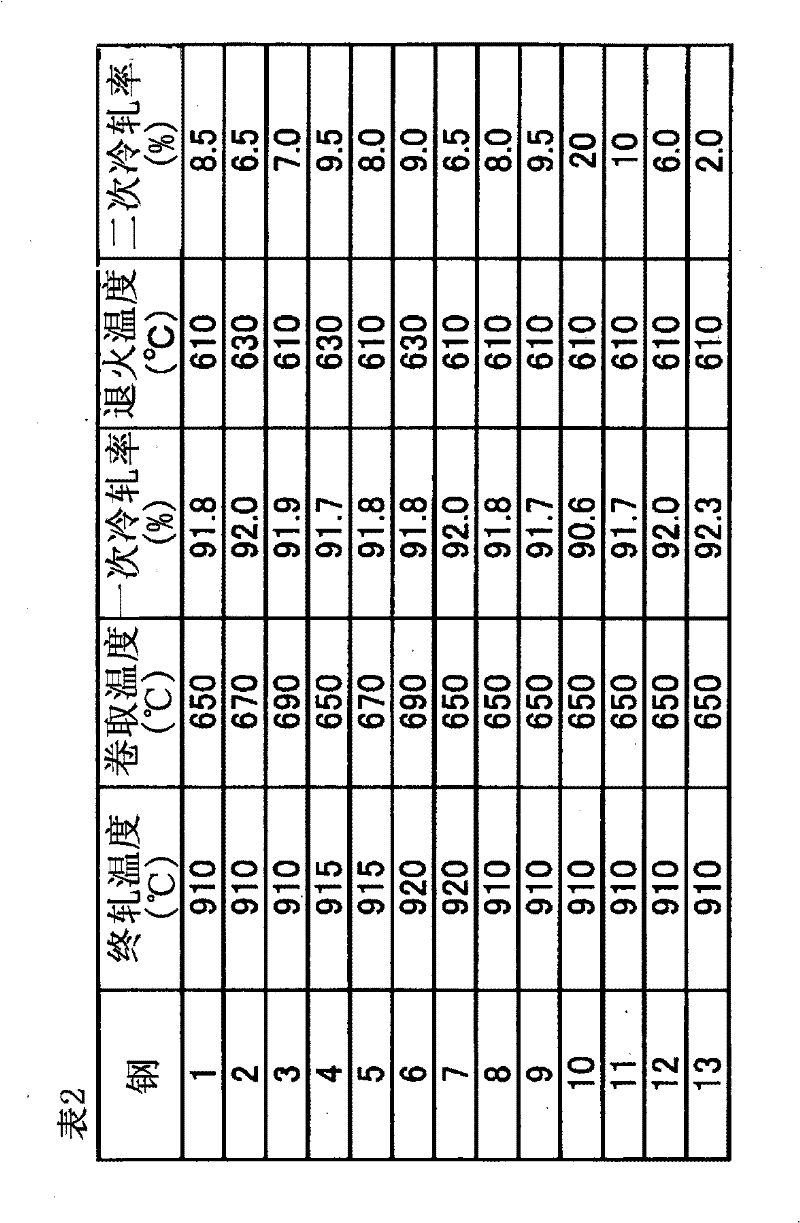

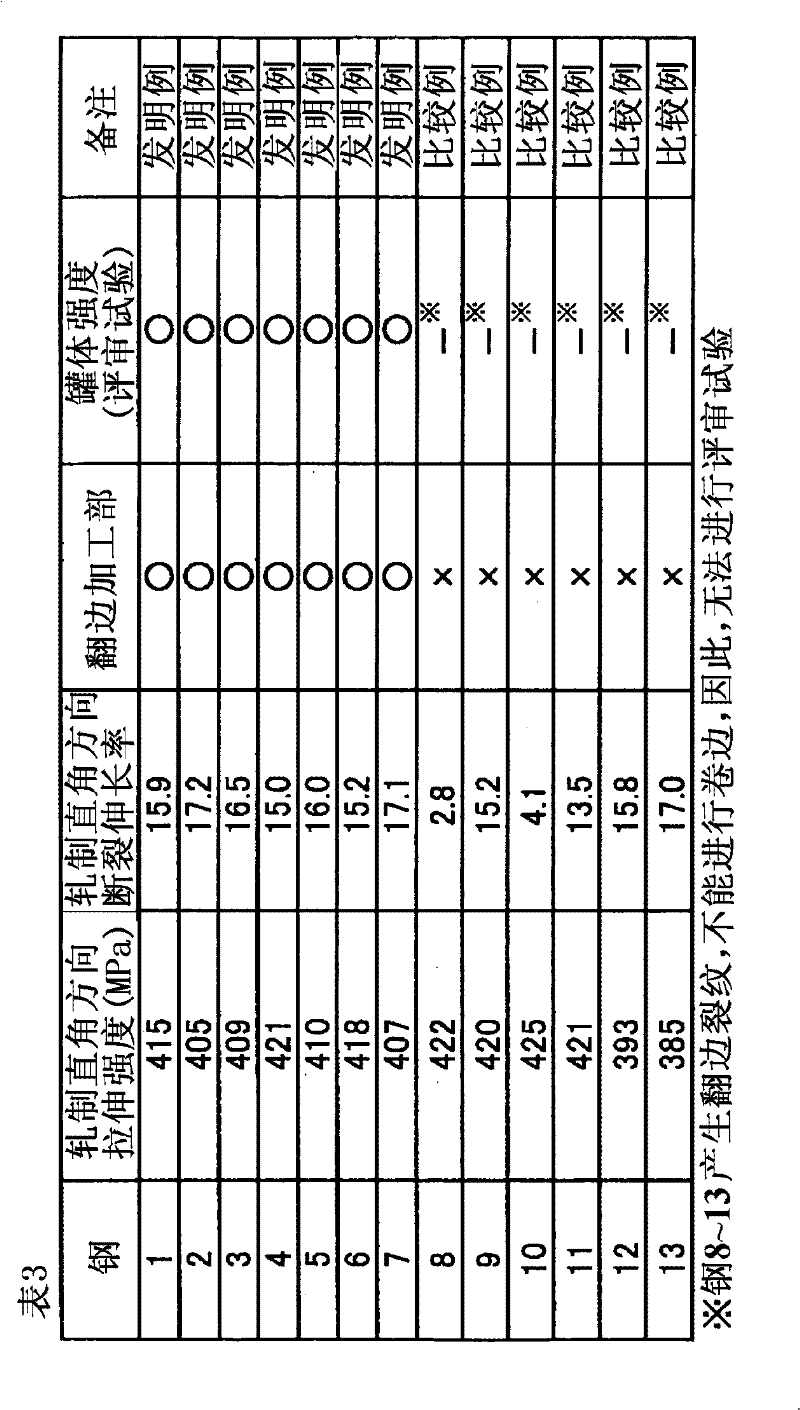

[0070] Steel containing the composition shown in Table 1, with the balance consisting of Fe and unavoidable impurities was melted in an actual converter, and a billet was obtained by continuous casting. Next, the obtained steel slab was reheated at 1250° C., and hot rolling, primary cold rolling, continuous annealing, and secondary cold rolling were performed under the conditions shown in Table 2 to produce a plate of 0.14 to 0.15 mm. thick. Pickling is carried out after hot rolling. The two surfaces of the steel sheet manufactured as above were continuously plated with Sn, and the amount of Sn deposited on one side was 2.8g / m 2 of tin-plated steel.

[0071]

[0072]

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com