Novel fume hood

A fume hood, a new type of technology, applied in the directions of removing smoke and dust, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of air and temperature loss, inconvenience of experimenters, air pressure imbalance, etc., to reduce energy consumption and air. Loss, easy experimental operation, reducing room temperature and the effect of air loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

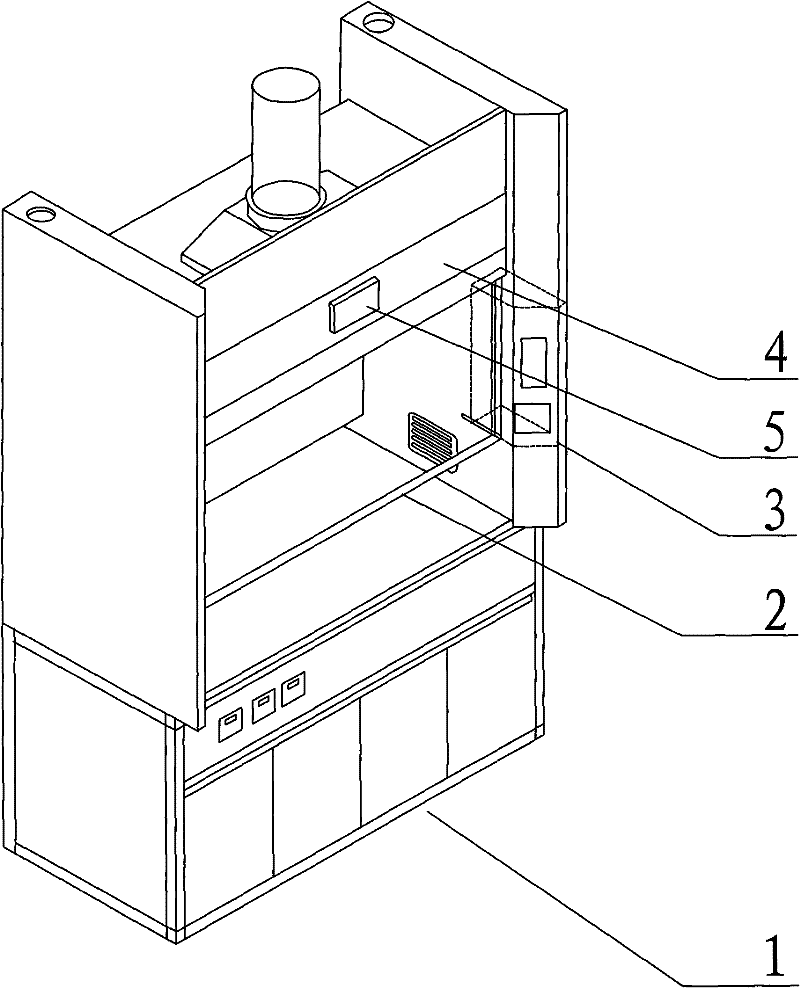

[0022] Such as figure 1 As shown, the novel fume hood includes a cabinet body 1, a safety sliding door 2 is provided on the front side of the cabinet body 1, a central control system 3 on the cabinet body 1, and lighting equipment is arranged on the top of the cabinet body 1 to ensure that the light is good during operation (illuminance Not less than 400LUX); the cabinet is divided into upper and lower layers, the upper part is the experimental operation part, and the lower part can place experimental equipment and other items; the operating table is a solid physical and chemical board, which is resistant to strong acids and alkalis. The countertop is recessed, which can store a certain volume of liquid and prevent harmful liquid from spilling out; the front of the cabinet 1 is also equipped with a surface wind speed sensor 5, which is electrically connected to the central control system 3, and is measured by measuring the air flow between the fume hood and the surrounding envi...

Embodiment 2

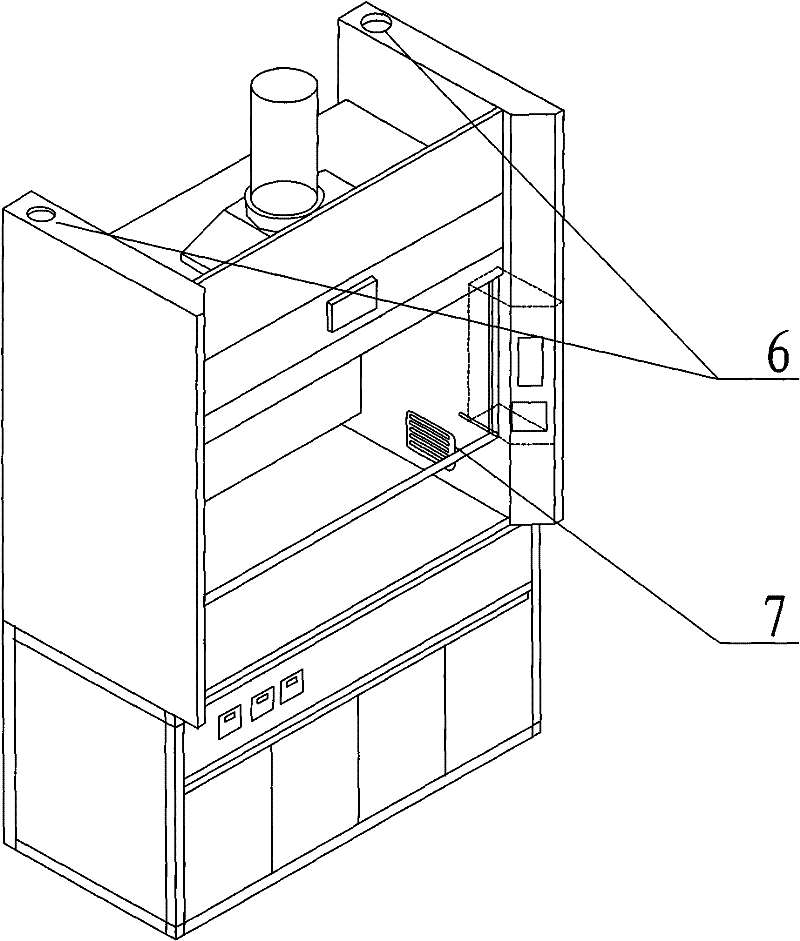

[0026] Such as figure 2 As shown, on the basis of Embodiment 1, a supplementary air outlet 7 is opened on the inner side of the cabinet body 1, and the outdoor fresh air is sent into the cabinet body 1 through an axial flow fan connected to a PVC air duct with a diameter of 90 mm. The central control system 3 is electrically connected with the axial flow fan, and the supplementary air volume can be controlled through the axial flow fan, and the outdoor fresh air is transmitted into the cabinet 1 through the supplementary air duct 6 at the top of the cabinet 1 .

Embodiment 3

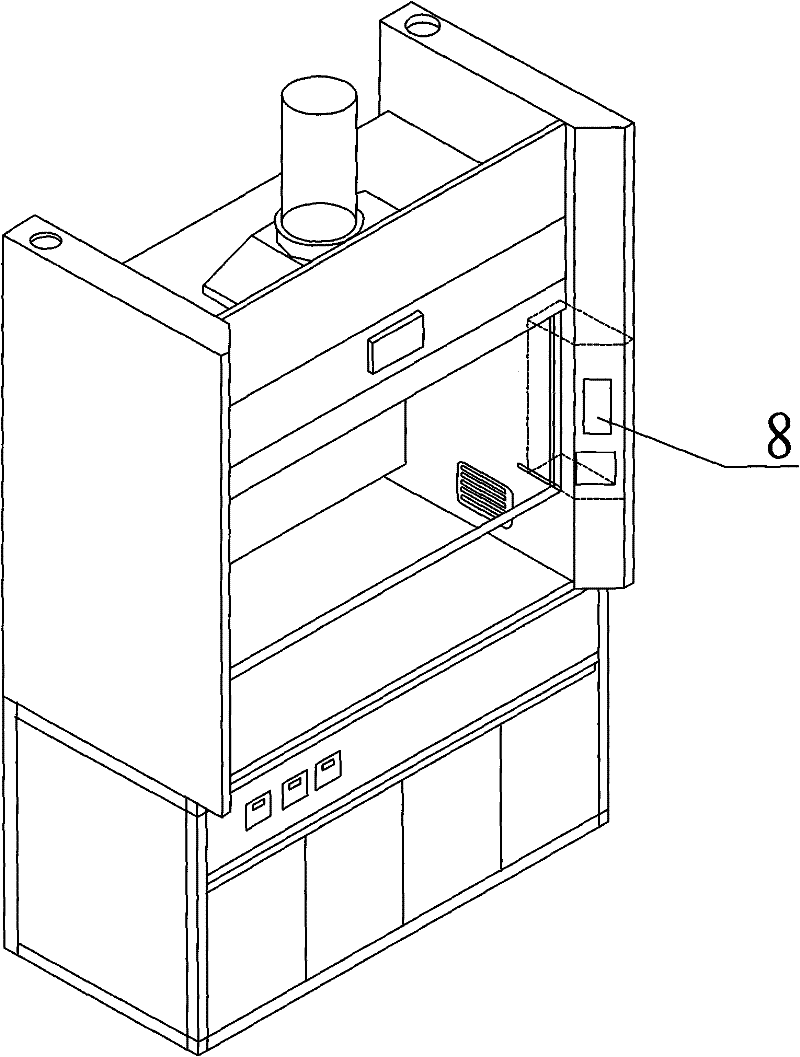

[0028] Such as image 3 , Figure 4 As shown, the overall technical solution of embodiment 3 is the same as that of embodiment 1, the difference is that the control panel 8 installed on the front of the cabinet body 1, the central control system 3 is electrically connected to the control panel 8, and the control panel 8 is optional The water and air control valves are located on the right hand side of the best position for human operation. Control panel 8 comprises fan switch 81, emergency switch 82, safety sliding door opening key 83, safety sliding door closing key 84, light switch 85. The safety sliding door opening key 83 and the safety sliding door closing key 84 can be adjusted at any height; when the emergency switch 82 is started, the safety sliding door 2 is completely closed, and the exhaust air volume is adjusted to the maximum, avoiding the potential danger of the experiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com