Insertion system and method to insert insulators and coils in slots of stator of electric machine

A technology of insertion system, stator, applied in the field of electric motors, which can solve the problems of increased manufacturing costs, troublesome operation of slot liners, damage to motors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

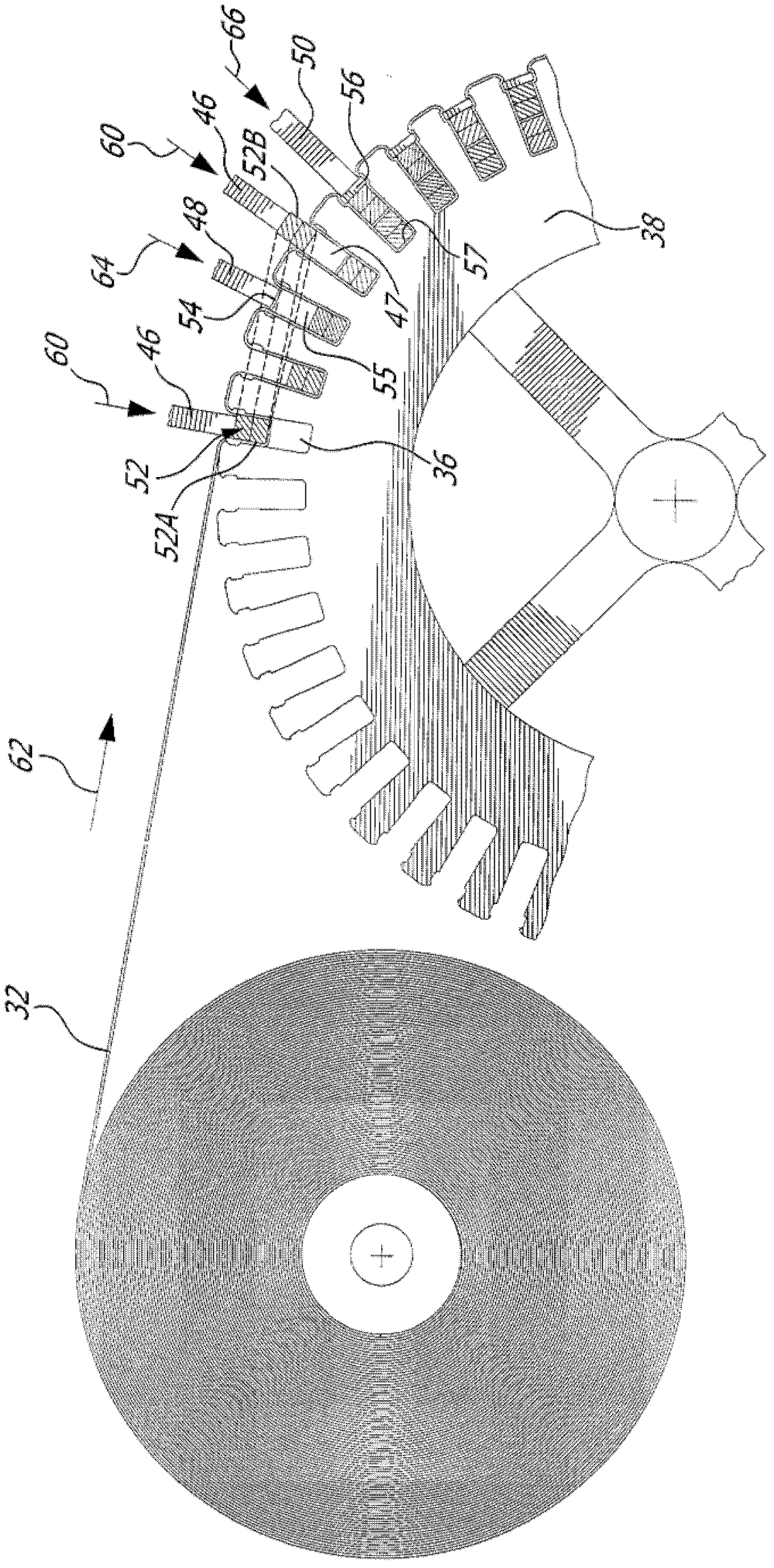

[0047] Turning now to the attached Figures 1 to 5 , an exemplary insertion system 30 according to a first illustrative embodiment will be described.

[0048] The insertion system 30 is designed for inserting a continuous insulating paper 32 in a longitudinal slot 36 of a stator 38 from a continuous paper roll 34 .

[0049]Insertion system 30 includes a rotating stator holder 42, schematically shown with four spokes 44, and two interconnected radially movable pre-coil holding and pushing members, referred to as pre-coil holders 46. The exemplary insertion system 30 optionally includes a radially moveable interface paper retaining member 48 and a radially moveable wedge retaining member 50 .

[0050] In fact, as those skilled in the art will readily understand, the insertion of the illustrated systems and methods discussed herein is also designed to insert interface insulating paper and wedges, which are optional and can be omitted.

[0051] If the system 30 is a manual syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com