Test hardware system for full-scale bit test

A technology for testing and hardware systems, applied to measuring devices, instruments, etc., can solve the problems of low automation, high hardware cost, and large limitations of extended functions, and achieve the effect of improving automation and simplifying the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

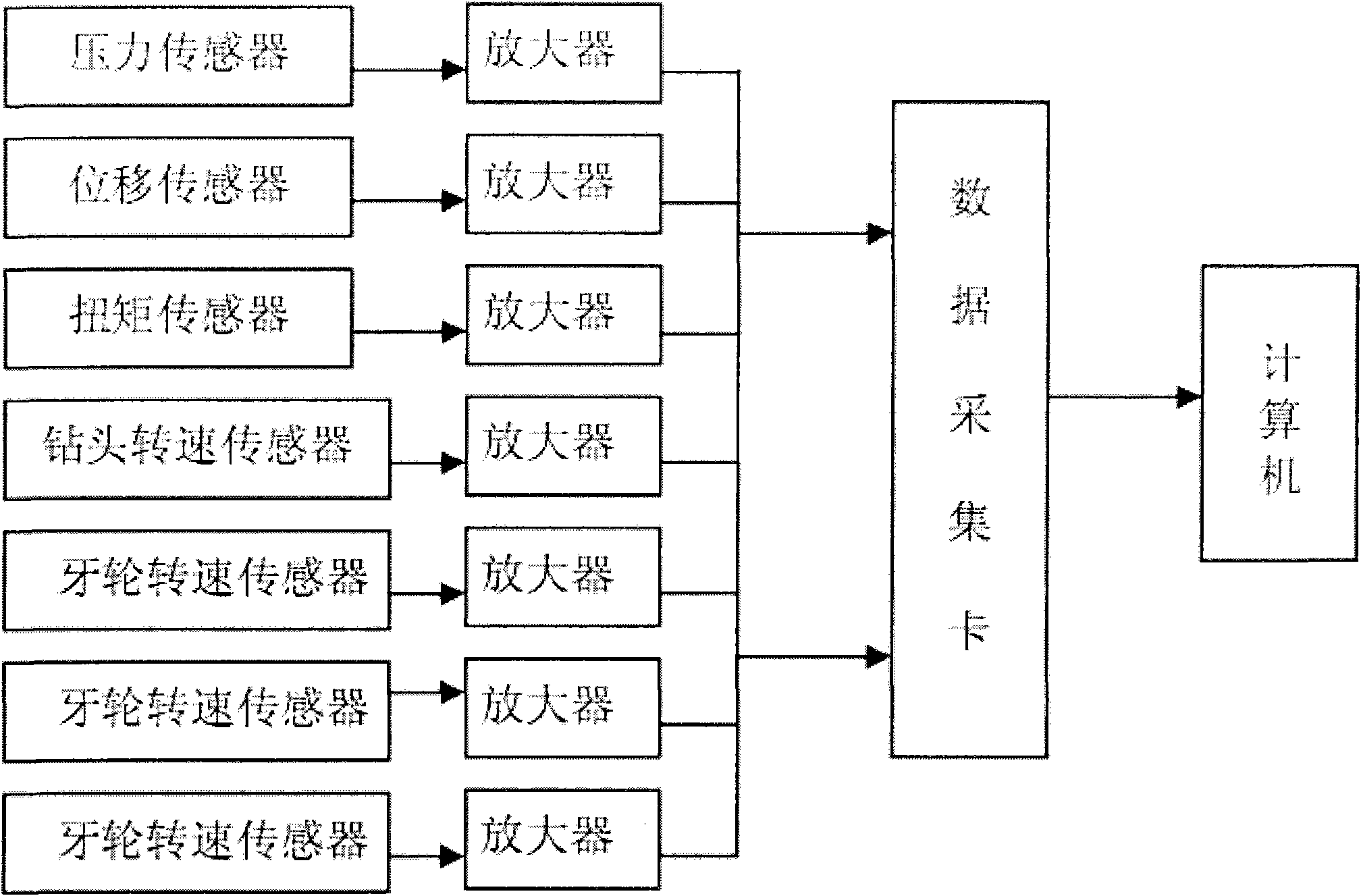

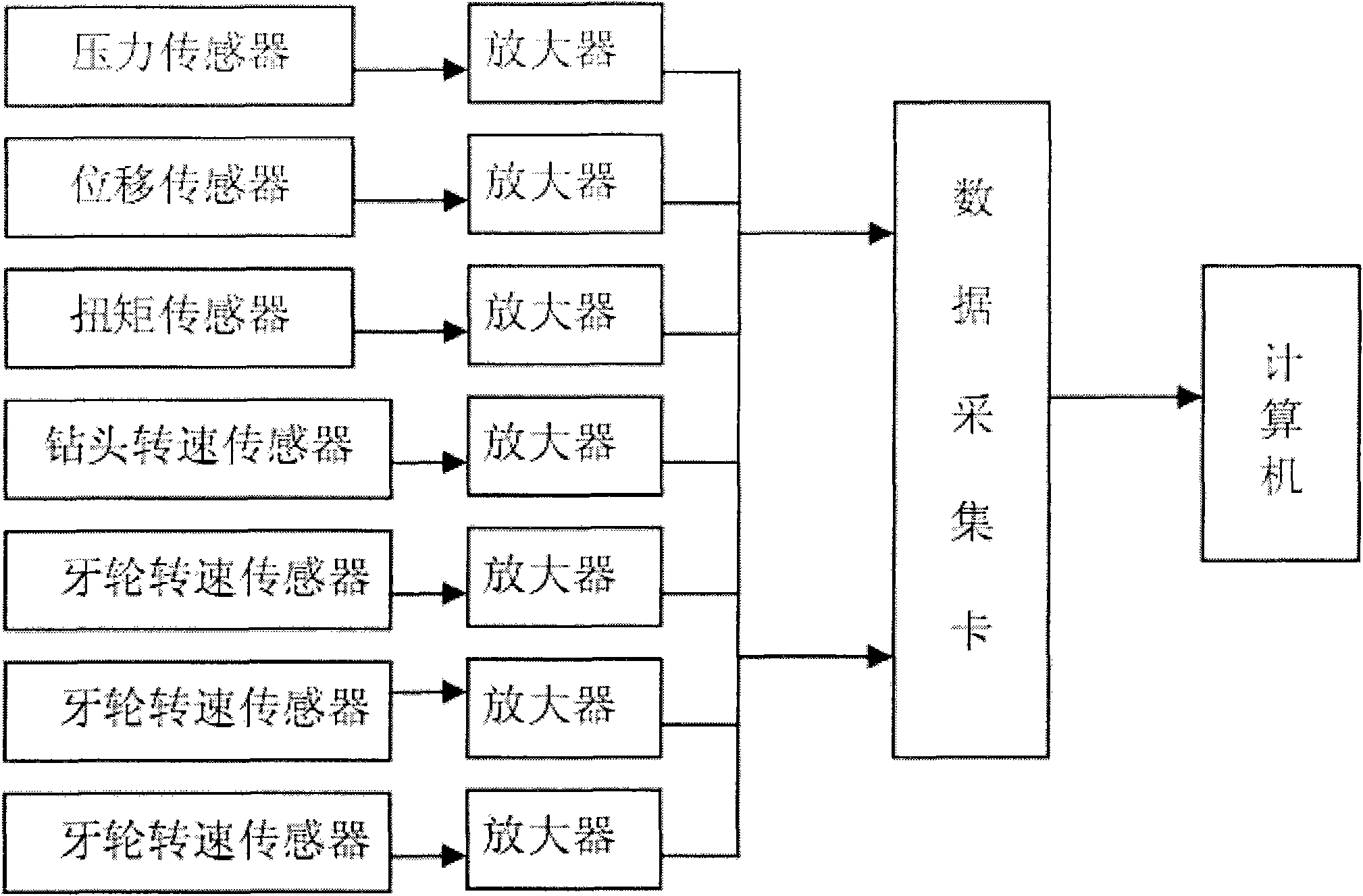

[0028] Such as figure 1 As shown, the present invention is mainly made of pressure sensor, displacement sensor, torque sensor, drill bit rotational speed sensor, and 3 cone rotational speed sensors, and described pressure sensor, displacement sensor, torque sensor, drill bit rotational speed sensor, and 3 cone rotational speed sensors The sensors are independently connected with amplifiers, all the amplifiers are connected with the same data acquisition card, and the data acquisition card is connected with the computer.

[0029] The full drill bit test needs to measure the WOB generated during the drilling process of the drill bit, and a tension pressure sensor can be installed between the measuring joint and the drill bit for measurement. This design selects the LTR-1M tension pressure sensor produced by Shanghai Zhendan Sensor Instrument Factory. The test principle is: using the principle of resistance strain, the high-precision foil strain gauge is pasted on the elastic bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com