Methane pressure stabilizing device and manufacturing process thereof

A technology of voltage stabilizer and production process, which is applied in biological sludge treatment, waste fuel and other directions to achieve the effect of prolonging life, reducing construction cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

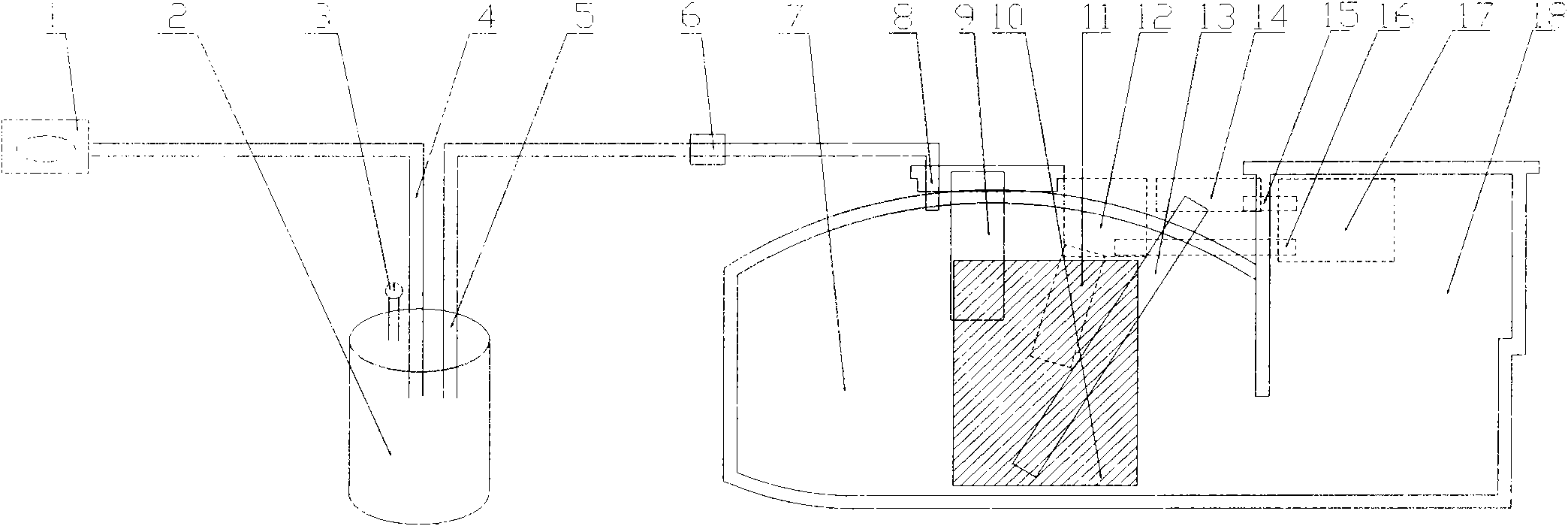

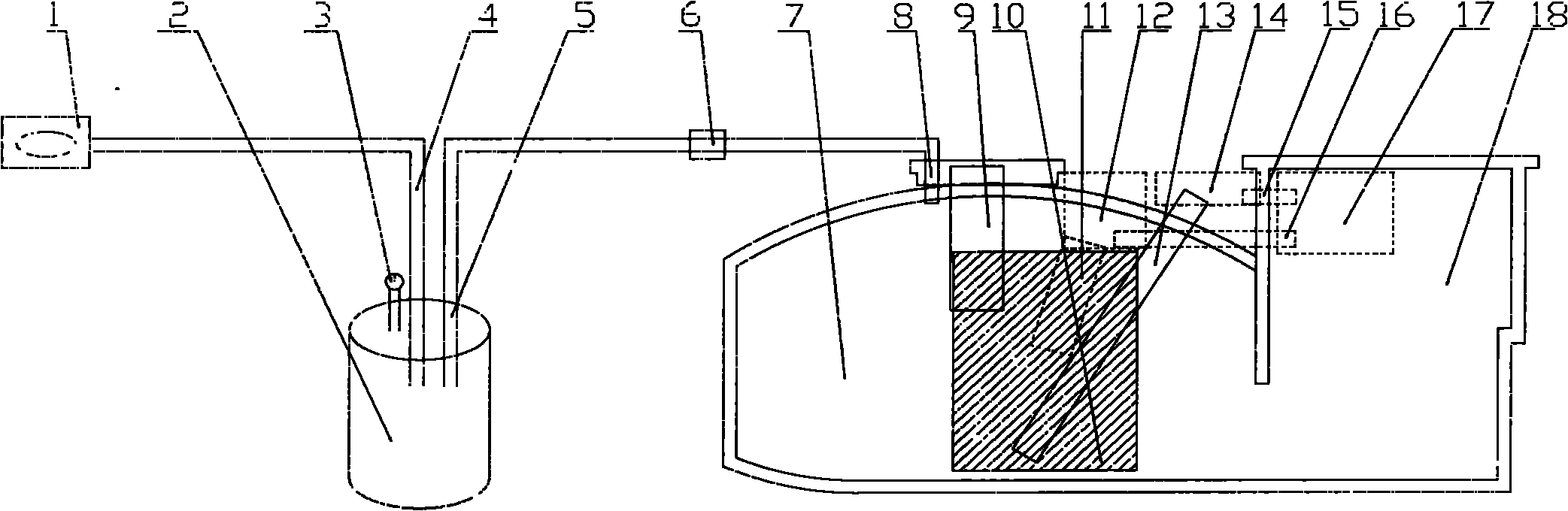

[0017] A biogas voltage stabilizing device and manufacturing process according to the present invention, the device includes: stove 1, gas storage tank 2, pressure relief valve 3, output biogas pipe 4, input biogas pipe 5, one-way valve 6, fermentation tank 7. Air guide pipe 8, closed pipe 9, cloth wall 10, feed pipe 11, feed port 12, discharge pipe 13, discharge port 14, guide pipe 15, return pipe 16, fertilizer storage room 17, water pressure Room 18.

[0018] The operation mode is: the feed port 12 is connected with the feed pipe 11 to transport the fermented material, the discharge pipe 13 is connected with the discharge port 14 to extract the fermentation liquid residue, and the fermented liquid waste residue is discharged to the discharge port 14 , the waste residue of the fermentation liquid material in the discharge port 14 is separated, and the liquid material that can continue to be fermented is separated, and the liquid material that continues to be fermented is tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com