Ultra-thin folding nail clipper

A foldable, nail clipper technology, applied in the field of nail clippers, can solve problems such as hidden dangers of nail clippers safety, inability to achieve durability, and damage to the knife edge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

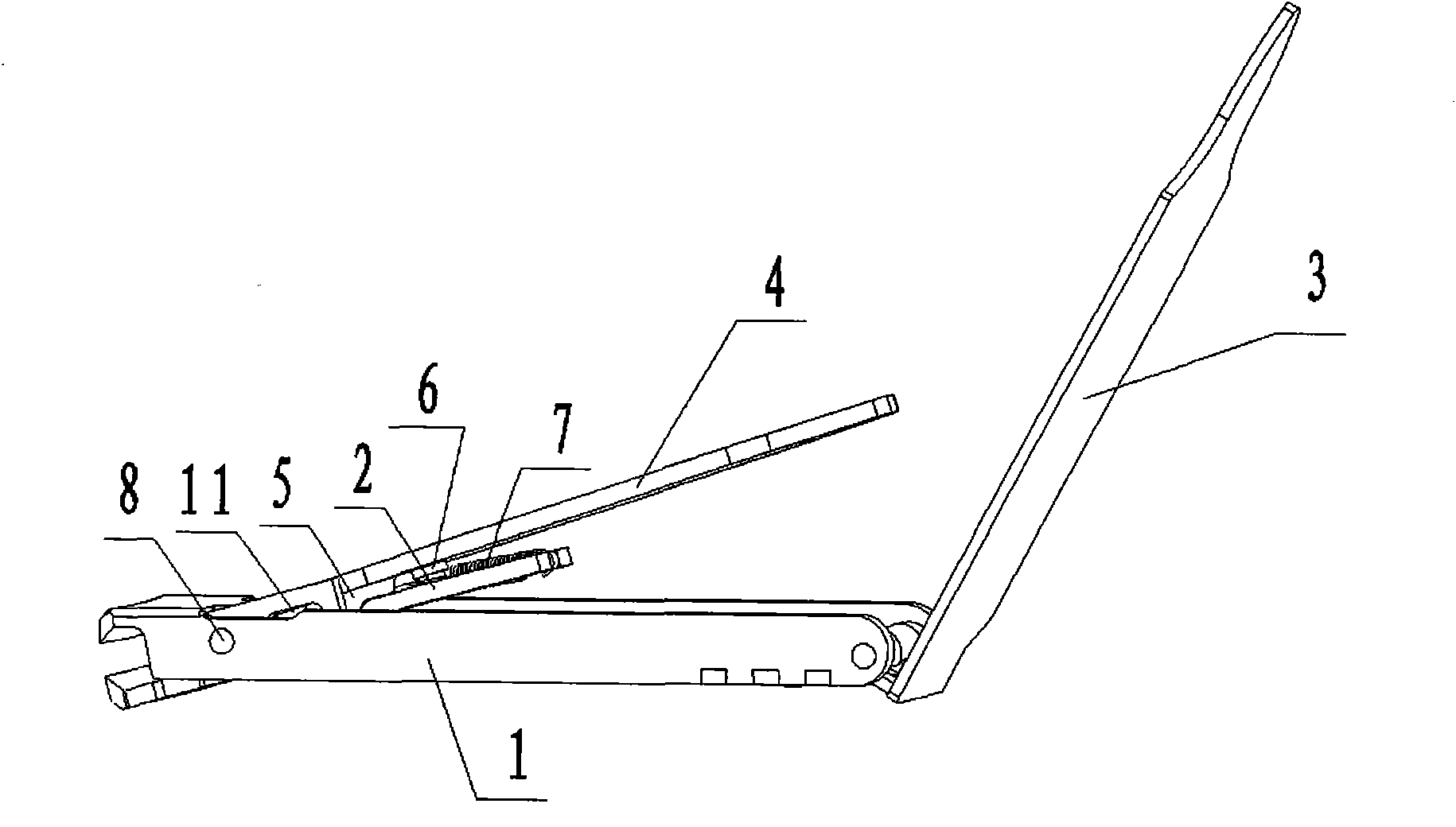

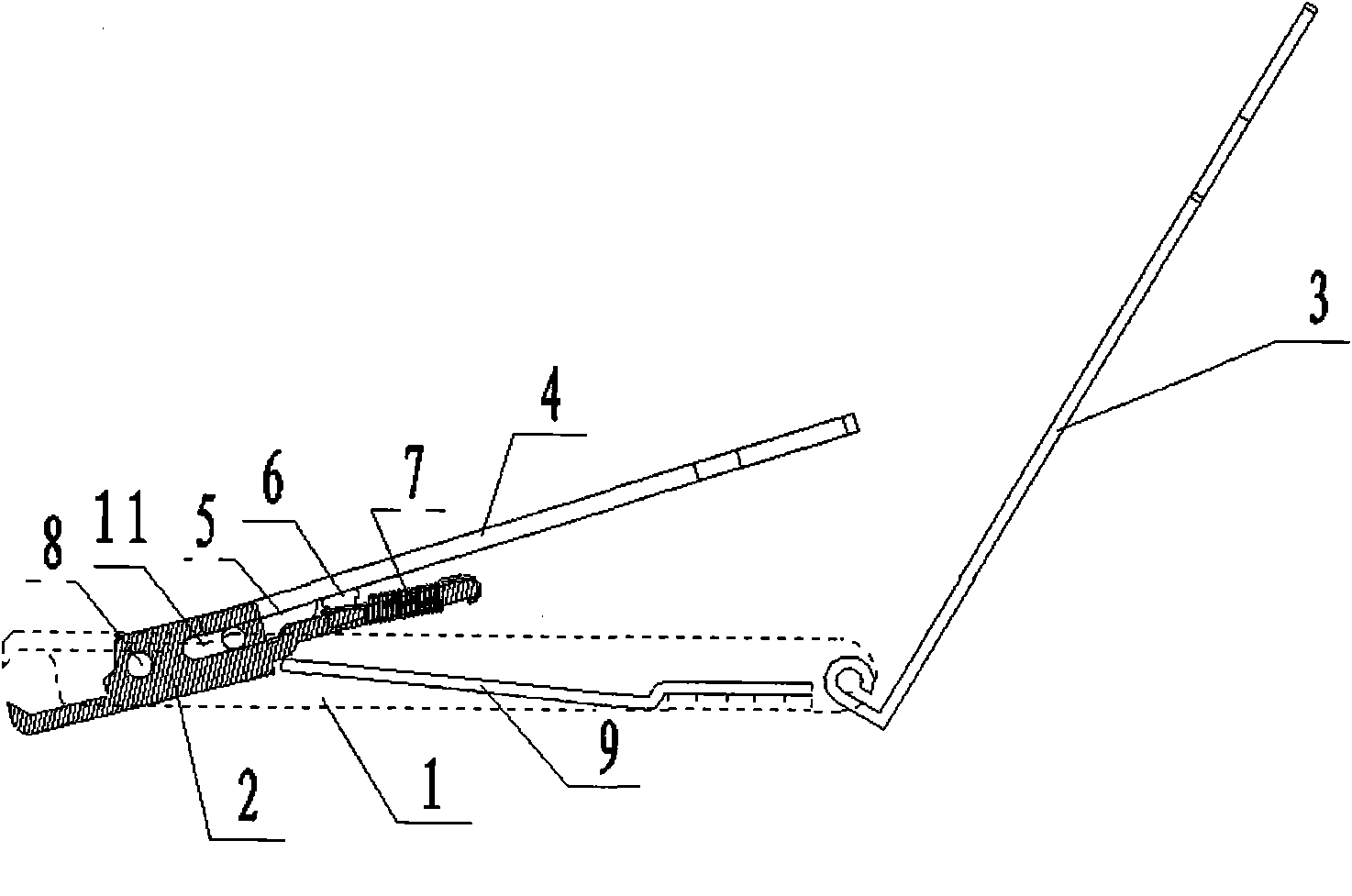

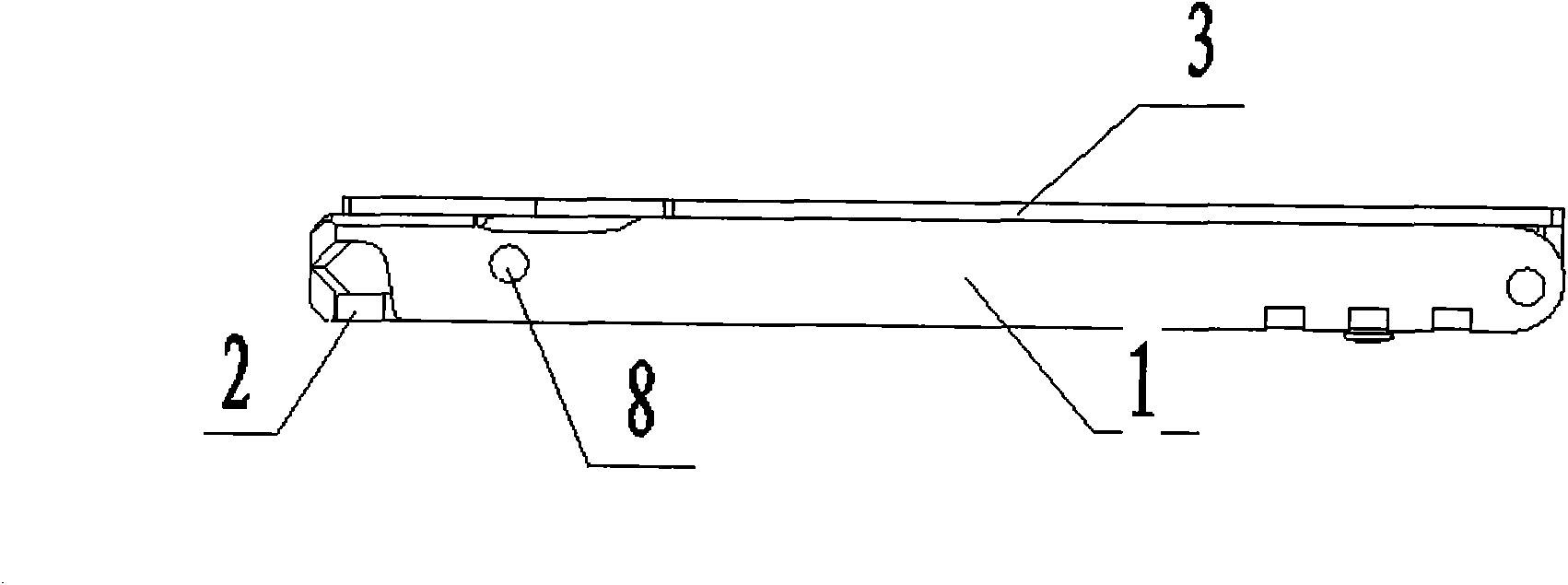

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0016] like figure 1 As shown, the fixed pliers body 1 is a frame structure, and its front end is an arc-shaped knife edge, and the movable pliers body 2 is pivotally connected in the frame of the fixed pliers body 1 by a pivot 8, and the front end of the movable pliers body 2 also has An arc-shaped knife-edge corresponds to the knife-edge of the fixed pliers body 1, the end of the spring leaf 9 is fixed on the rear of the fixed pliers body 1, and the front end is offset against the movable pliers body 2, so that the two knife-edges of the nail clippers always have an elastic force to open .

[0017] The front end of the depression bar 4 is fixed as a whole with the connection block 5, as Figures 4 to 6 As shown, a cylindrical protruding block is respectively provided on both sides of the connecting block 5, and a strip-shaped hole 11 is respectively provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com