Method for manufacturing raw pueraria powder

A production method and technology of raw powder, which is applied in the field of production of root crop kudzu root powder, can solve the problems of reduced benefit, large loss, affecting the original taste and quality of the product, and achieves the effect of no change in activity and zero loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

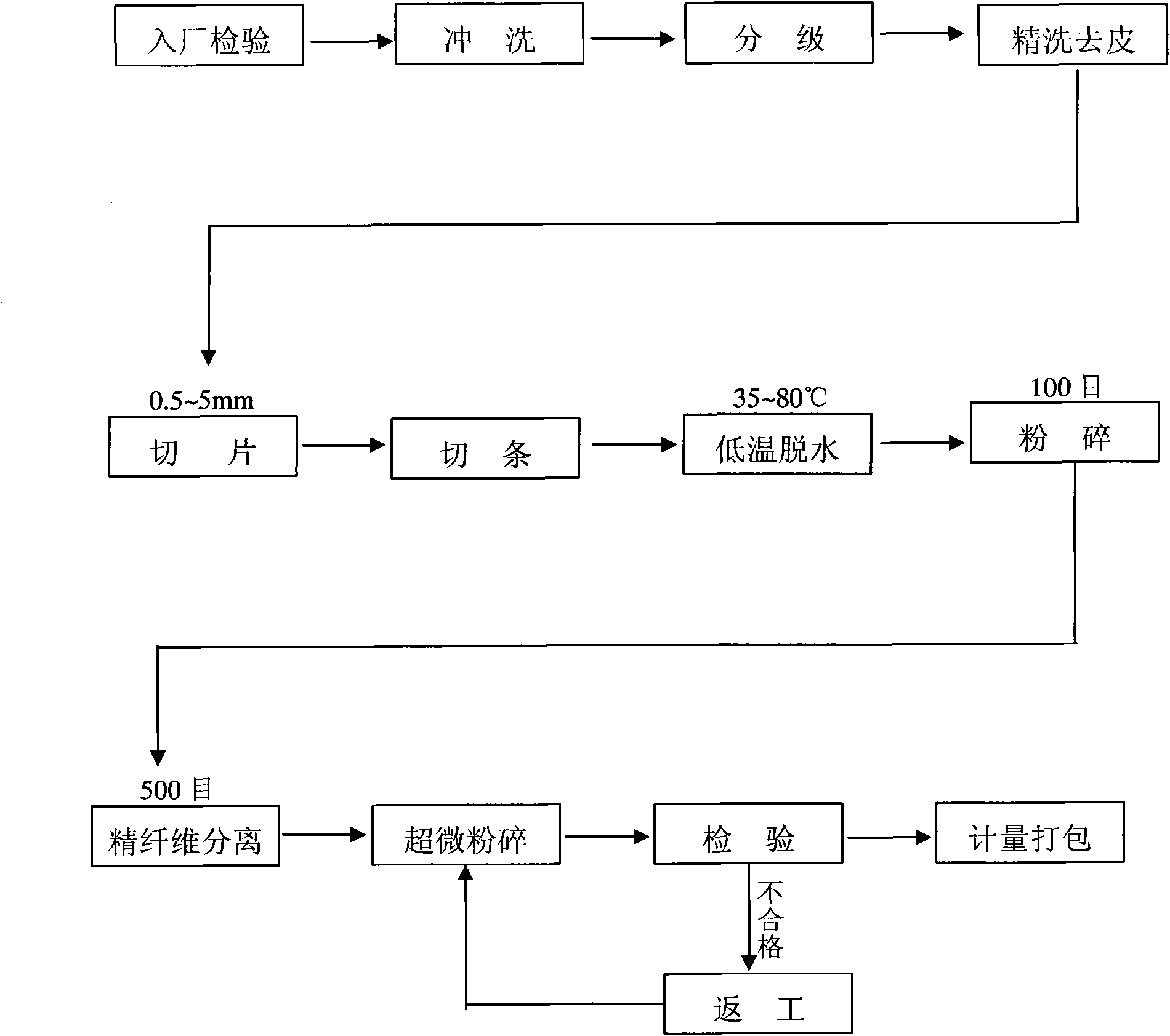

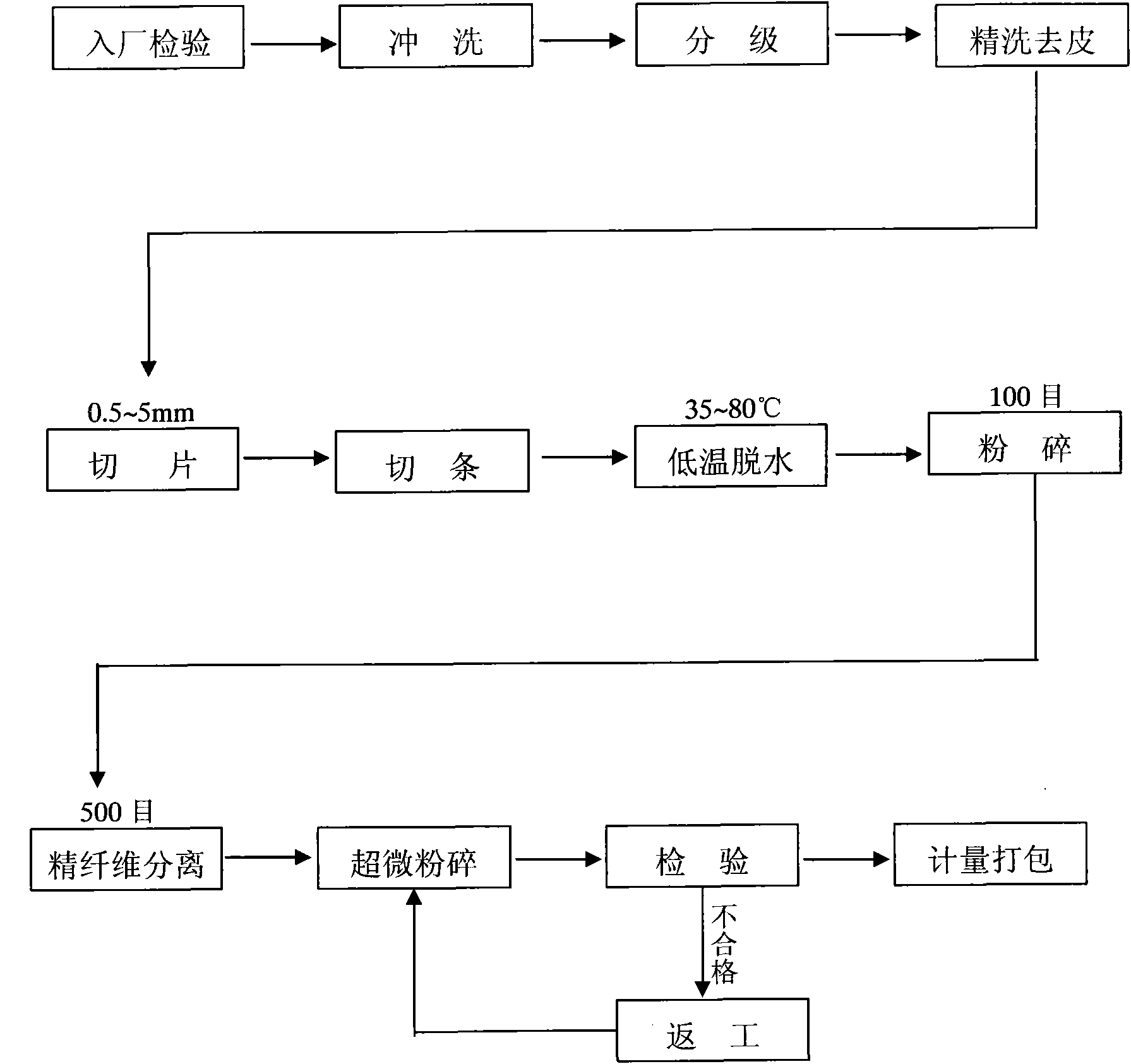

Image

Examples

Example Embodiment

[0007] Pueraria lobata has passed inspection after entering the factory and cleaned to ensure 100% removal of sediment. Then, trim the branch-shaped raw material and the raw material longer than 30cm. After washing and peeling, slicing or dicing is carried out. During the slicing process, the thickness of the slices is uniform and the cut surface is free of hair. After that, the slices or dicing are dehydrated and dried. During the process from slicing or dicing to conveying into the dehydration dryer, it must be clean and hygienic, free of debris and pollution. The dehydration drying temperature is controlled between 3580℃, the highest is not higher than 80℃, and the whole dehydration drying time is 60~75 minutes. When the water content of the raw material reaches 150%, it is cooled, pulverized, coarse fiber separated, superfine pulverized, and sieved. In the ultrafine grinding, the mesh size can be adjusted according to the product requirements, generally 500-800 mesh. Fin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com