Method and apparatus for sterilizing footwear

A technology of a disinfection device and a disinfection method, which is applied to footwear, disinfection, water supply devices, etc., can solve the problems of ineffective disinfection process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

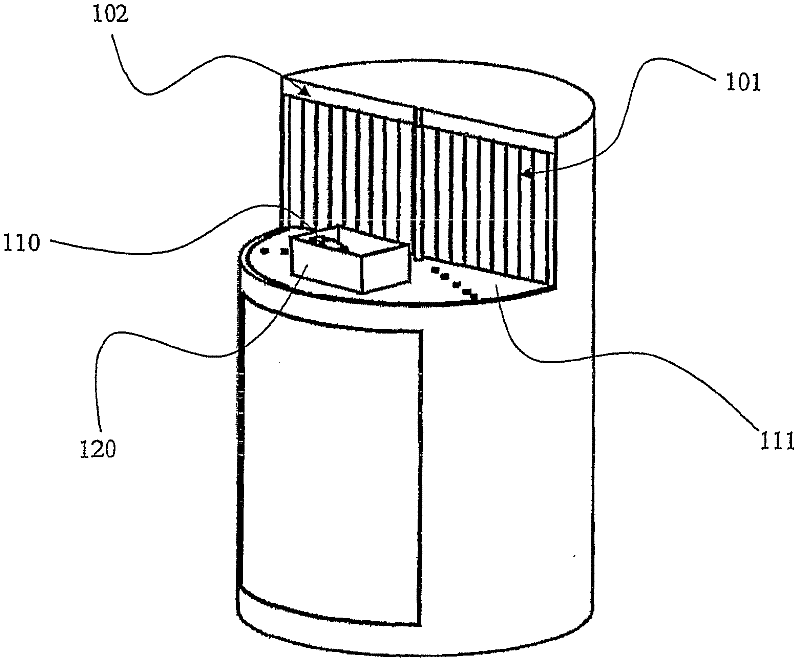

[0027] refer to figure 1 In the preferred embodiment shown here, the shoe disinfection device according to the invention comprises two disinfection tanks 1, 2 and a device 3 for transporting footwear 10 from the inlet of the disinfection tanks 1 and 2 to the outlet thereof. The embodiment described here comprises two sterilization cases 1 and 2 that are independently and interchangeably placed one after the other, and those skilled in the art can understand that, according to the degree of sterilization required, more sterilization cases can be provided, The footwear can be placed inside and transported with the device 3 .

[0028] Each of said sterilization boxes 1 and 2 is provided with an inlet section and an outlet section through which said footwear is conveyed for said sterilization step. The disinfection chambers 1 and 2 are provided with means 4 for generating heat and 5 for generating ultraviolet rays, both known per se in the art, for the disinfection of footwear. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com