Hydraulic jet impacter

A technology of impactor and jet element, applied in the field of hydrodynamic jet impactor, can solve the problems of end face erosion, cylinder deformation, high-pressure mud leakage, etc., to improve the flow structure, reduce the erosion effect, and improve the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

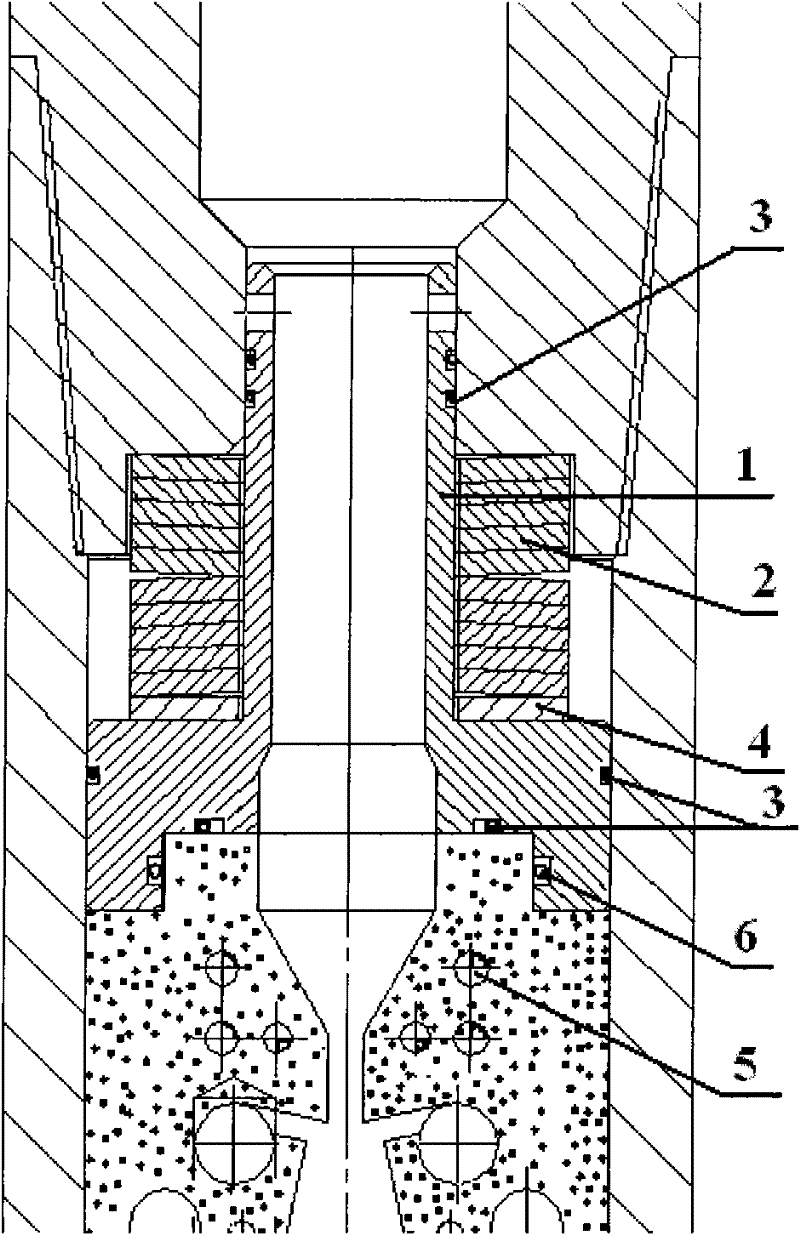

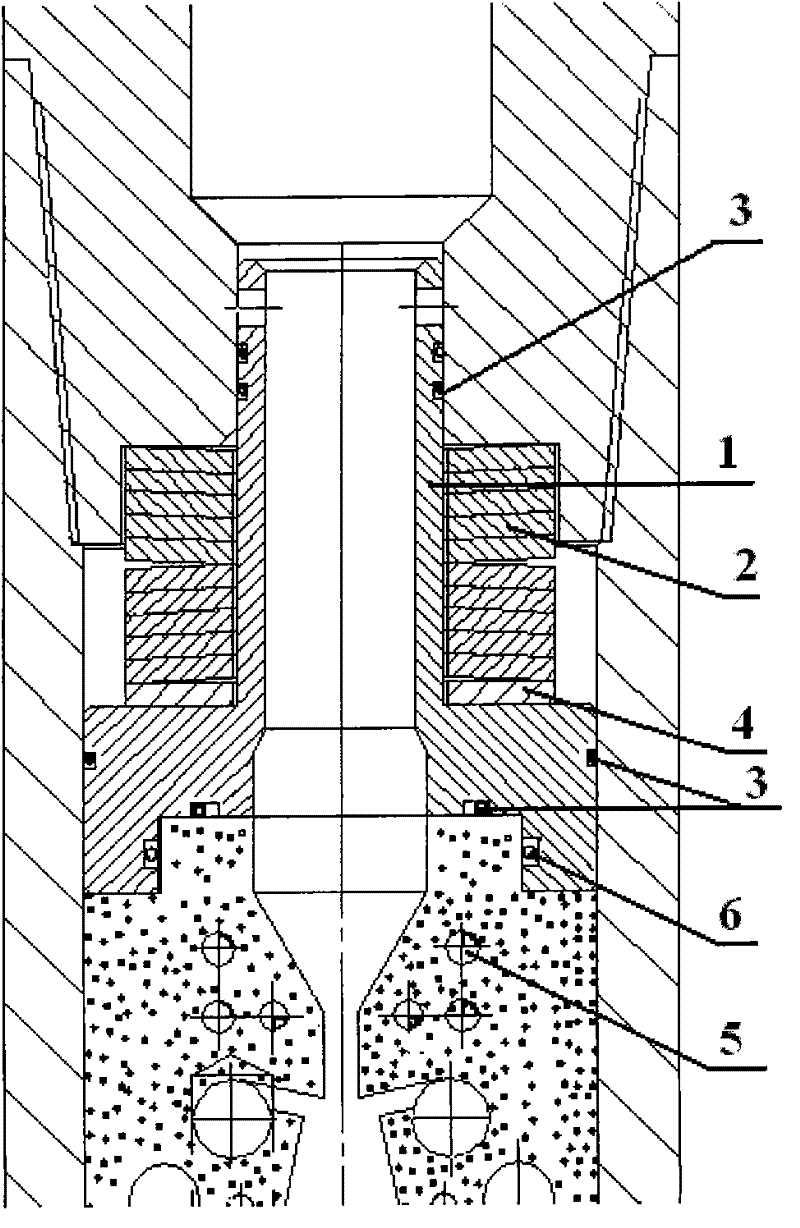

[0022] Such as figure 2 As shown, a hydraulic jet impactor includes an upper joint, a disc spring frame 1, a disc spring 2, a sealing ring 3, an adjusting washer 4, and a fluidic element 5; the bottom of the disc spring frame 1 is pressed against the The upper part of the jet element 5, the disc spring 2 is set on the neck of the disc spring frame 1, the upper part of the disc spring 2 is pressed against the lower part of the upper joint, and the bottom is pressed against the disc spring On the shoulder of the frame 1, the adjusting washer 4 is fixed between the shoulder of the disc spring frame 1 and the bottom of the disc spring 2, wherein,

[0023] The belleville spring 2 adopts a composite composite structure, the number of composite layers is 2 layers, and the upper and lower layers are respectively formed by stacking 5 discs;

[0024] The openings of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com